Apple-shaped hollow molecular sieve microspheres and preparation method and application thereof

A molecular sieve and hollow technology, applied in the field of molecular sieves, can solve the problems such as difficulty in exerting the advantages of spatial confinement effect and channel folding, catalyst particles unable to form a hollow structure, and limited application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

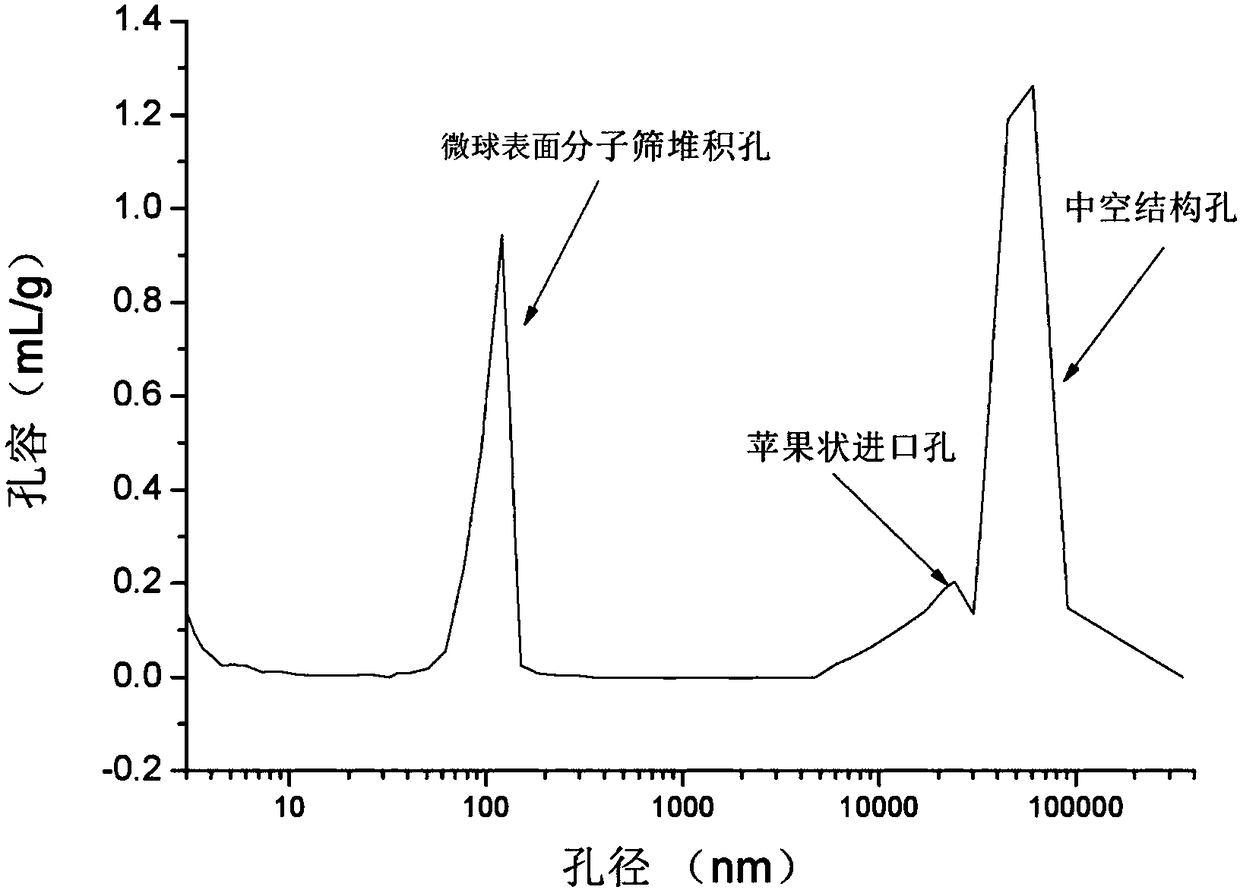

[0030] The invention provides a method for preparing apple-shaped hollow molecular sieve microspheres, comprising the following steps:

[0031] (1) Homogenizing molecular sieves, binders, pore-forming agents and water to obtain colloidal slurry;

[0032] (2) mixing and emulsifying the colloid slurry obtained in the step (1) with a surfactant to obtain a microsphere emulsion;

[0033] (3) The microsphere emulsion obtained in the step (2) is subjected to balling treatment by spray drying method to obtain primary microspheres;

[0034] (4) Calcining the primary microspheres obtained in the step (3) to obtain apple-shaped hollow molecular sieve microspheres.

[0035] The invention homogenizes molecular sieve, binder, pore-forming agent and water to obtain colloid slurry. In the present invention, the solid content of the colloidal slurry is preferably 20-45%, more preferably 30-45%, more preferably 42-43%; the solid content of the colloidal slurry refers to the dried colloidal s...

Embodiment 1

[0063] (1) Take 5.5kg of HZSM-5 molecular sieve with a grain size of 300-350nm, 3kg of kaolin, 1kg of cement and 0.5kg of ammonium carbonate into 20kg of deionized water, and use a homogeneous emulsifier to perform shear emulsification at 2000rpm for 2 hours to form Uniform colloidal slurry, the solid content of the colloidal slurry is 31.7%.

[0064] (2) Add 300 g of P123 surfactant to the colloid slurry, and continue stirring for 1 hour to obtain a microsphere slurry.

[0065] (3) Transport the above-mentioned microsphere slurry to the spray dryer, the atomization pressure of the spray dryer is 2.8Mpa, the inlet temperature of the atomization dryer is 280°C, and the outlet temperature is 120°C. The outlet flows out to obtain primary microsphere particles.

[0066] (4) The spray-dried microspheres were heated to 600° C. in a muffle furnace at a rate of 2° C. / min, and then calcined for 4 hours to obtain apple-shaped hollow molecular sieve microspheres.

[0067] Scanning elec...

Embodiment 2

[0070] (1) Take 4.5kg of SAPO-34 molecular sieve with a grain size of 400-500nm, 4kg of attapulgite powder, 1kg of kaolin, 0.3kg of urea and 0.2kg of ammonium nitrate into 15kg of deionized water, and use a homogeneous emulsifier to shear at 2000rpm Cut and emulsify for 2 hours to form a uniform colloidal slurry with a solid content of 38.0%.

[0071] (2) Add 600 g of cetyltrimethylammonium bromide surfactant to the colloid slurry and continue stirring for 1 hour to obtain a microsphere slurry.

[0072] (3) Transport the above-mentioned microsphere slurry to a spray dryer, the atomization pressure of the spray dryer is 2.5Mpa, the inlet temperature of the atomization dryer is 300°C, and the outlet temperature is 130°C, and the spray dryer is sprayed for 2 to 5 seconds. The outlet flows out to obtain primary microsphere particles.

[0073] (4) The spray-dried microspheres were heated to 580° C. in a muffle furnace at a rate of 2° C. / min, and then calcined for 5 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com