Preparation method of maleic hydrazide

A technology of maleic hydrazide and hydrazine hydrate, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of large waste discharge, difficulty in wastewater treatment, and high treatment costs, and achieve waste disposal. The effect of low emission, good catalytic effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

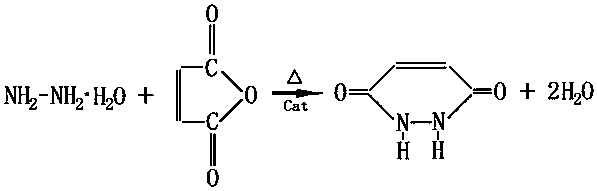

Method used

Image

Examples

Embodiment 1

[0011] With 200g of maleic anhydride, 250g of hydrazine hydrate and ZnCl with a content of 80% 2 / CuCl 2 Put 20g of the composite catalyst in a four-necked flask with stirring, thermometer and rectification column, start the stirring, heat up to reflux, when the steam enters the rectification column, extract water vapor at the column top temperature of 98°C to 100°C, and in the reflux React at high temperature for 4 to 6 hours. When there is no condensed water flowing out from the top of the rectifying column, the reaction is ended. Use vacuum distillation to distill all the remaining hydrazine hydrate in the flask, then cool the flask to normal temperature, add an appropriate amount of pure water, and start stirring , after the solid matter in the flask is stirred into a slurry, it is put into a centrifugal filter to filter, and then the filter cake is washed with an appropriate amount of pure water, and the washed filter cake is centrifugally dehydrated and dried to obtain 2...

Embodiment 2

[0013] Maleic anhydride 200g, hydrazine hydrate 280g and ZnCl with a content of 90% 2 / CuCl 2 Put 30g of composite catalyst in a four-neck flask with stirring, thermometer and rectification column, start stirring, heat up to reflux, when the steam enters the rectification column, extract water vapor at the column top temperature of 98°C to 100°C, and in the reflux React at high temperature for 4 to 6 hours. When there is no condensed water flowing out from the top of the rectifying column, the reaction is ended. Use vacuum distillation to distill all the remaining hydrazine hydrate in the flask, then cool the flask to normal temperature, add an appropriate amount of pure water, and start stirring , after the solid matter in the flask is stirred into a slurry, put it into a centrifugal filter to filter, then wash the filter cake with an appropriate amount of pure water, and the washed filter cake obtains 221.4 g of maleic hydrazide through centrifugal dehydration and drying.

Embodiment 3

[0015] Maleic anhydride 200g, hydrazine hydrate 300g and ZnCl with a content of 99% 2 / CuCl 2 Put 40g of the composite catalyst in a four-neck flask with stirring, thermometer and rectification column, start the stirring, heat up to reflux, when the steam enters the rectification column, extract water vapor at the column top temperature of 98°C to 100°C, and in the reflux React at high temperature for 4 to 6 hours. When there is no condensed water flowing out from the top of the rectifying column, the reaction is ended. Use vacuum distillation to distill all the remaining hydrazine hydrate in the flask, then cool the flask to normal temperature, add an appropriate amount of pure water, and start stirring After the solid matter in the flask is stirred into a slurry, put it into a centrifugal filter and filter, then wash the filter cake with an appropriate amount of pure water, and the washed filter cake obtains 223.6 g of maleic hydrazide through centrifugal dehydration and dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com