Novel nanopore organic framework solid alkali material

An organic framework and nano-organic technology, which is applied in the field of new nanoporous organic framework solid alkali materials, can solve problems such as poor carbon dioxide adsorption performance, achieve good carbon dioxide adsorption effect, overcome high preparation cost and good carbon dioxide adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

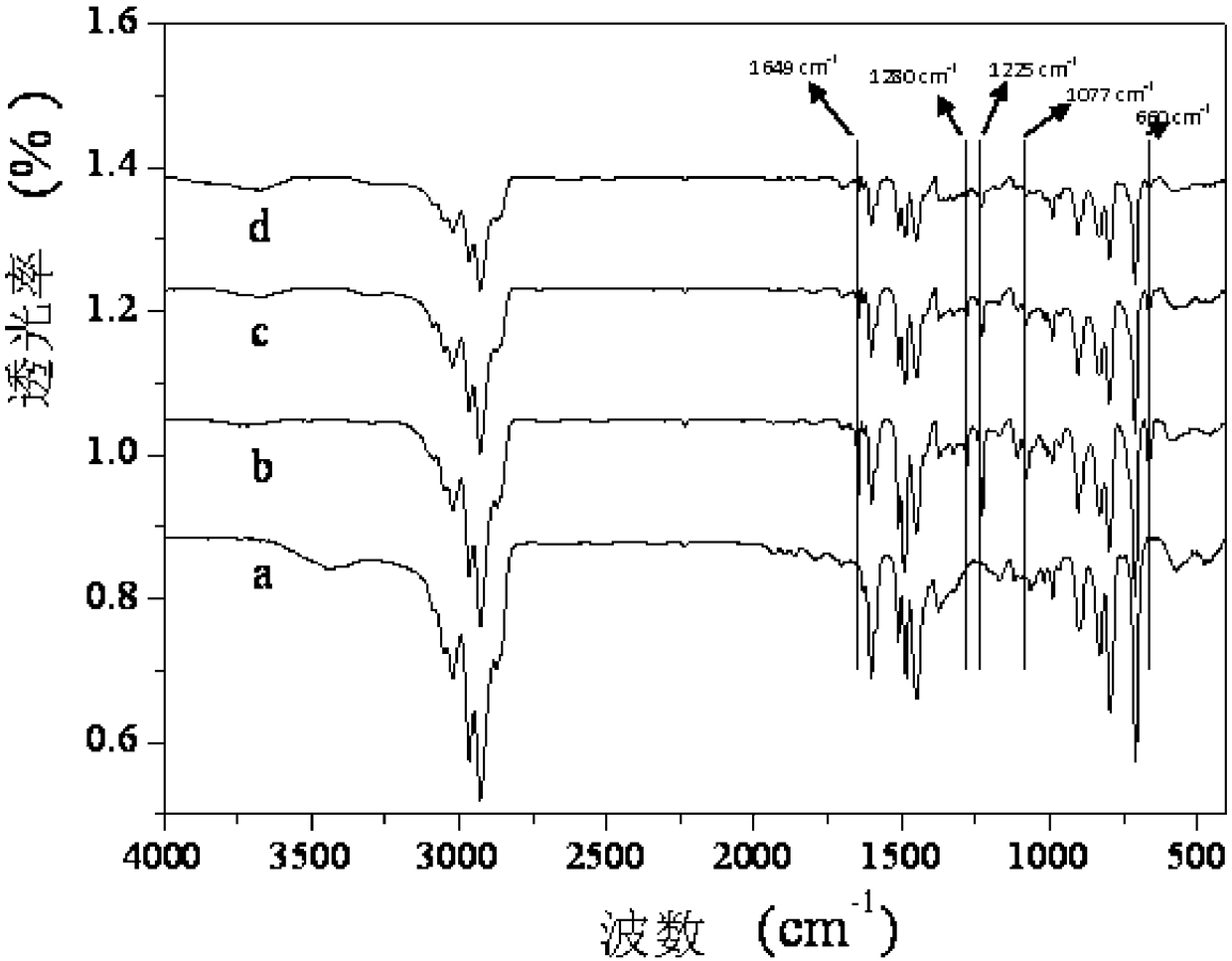

[0028] Embodiment 1: Synthesis of polyimidazole functionalized nanoporous solid alkali material

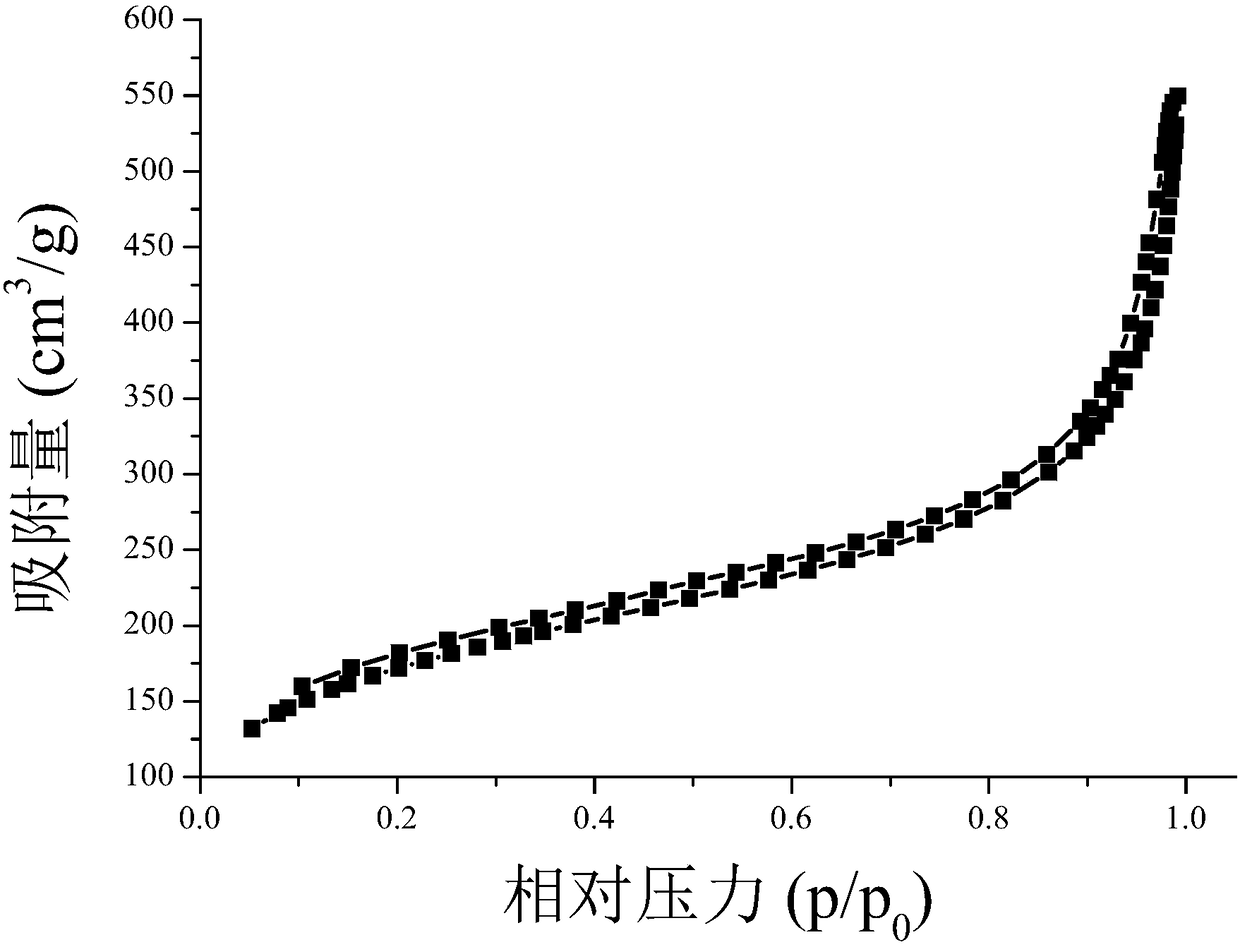

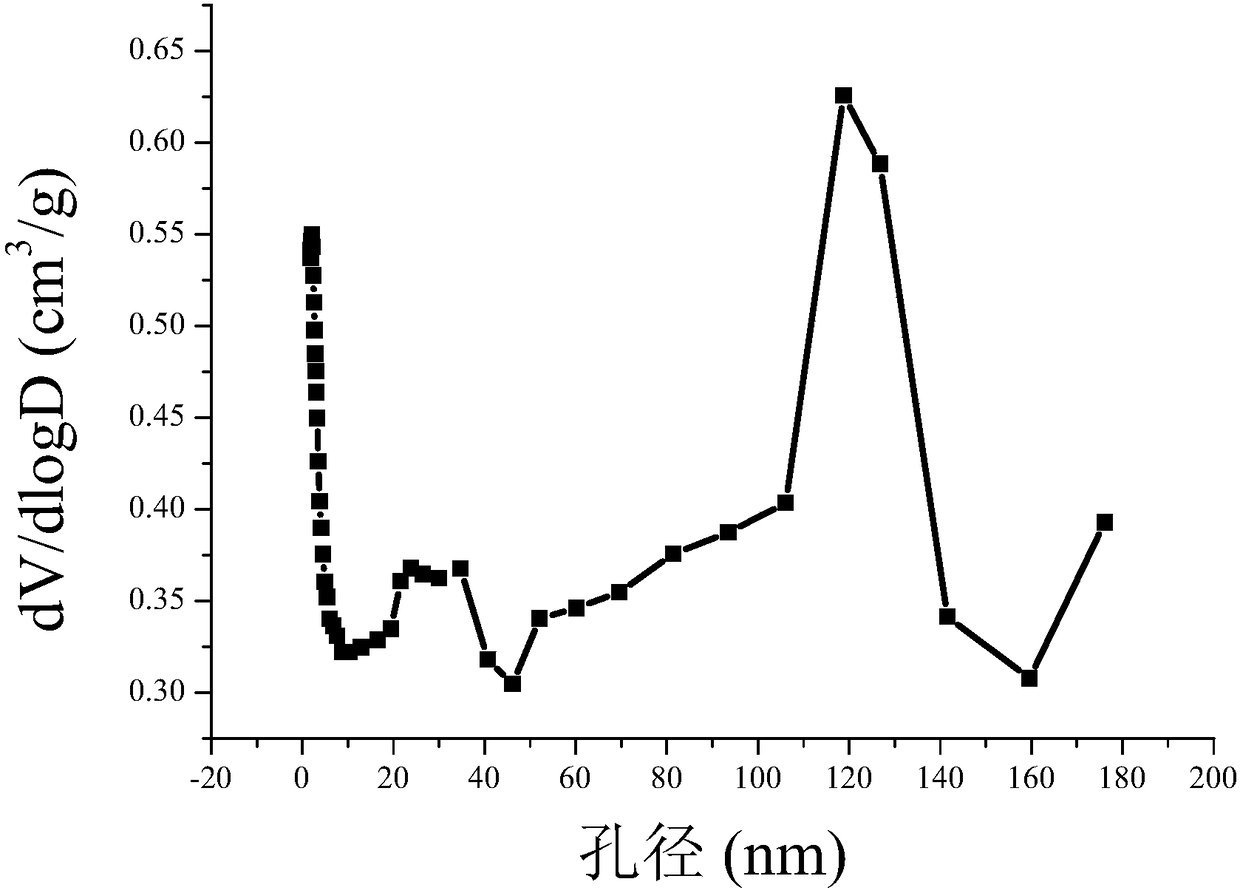

[0029] Disperse 0.020 g of azobisisobutyronitrile in 25 ml of dimethylformamide, then add 2.2 ml of divinylbenzene and 0.276 ml of tetravinylimidazole functional monomer, stir at room temperature for 3 hours, and fill the tank with a solvent at 180°C Heat treatment for 24 hours, open the cover, and volatilize the solvent to obtain a solid alkali material with a rich nanoporous structure, which is recorded as: PDVB-vim-5.0, and the specific surface area of the obtained material is 300m 2 / g, the pore volume is 0.3cm 3 / g.

Embodiment 2

[0030] Embodiment 2: Synthesis of polyimidazole functionalized nanoporous solid alkali material

[0031] Disperse 0.100 g of azobisisobutyronitrile in 30 ml of dimethylformamide, then add 2.2 ml of divinylbenzene and 2.76 ml of tetravinylimidazole functional monomers, stir at room temperature for 3 hours, and fill the tank with a solvent at 140°C Heat treatment for 24 hours, open the cover, and volatilize the solvent to obtain a solid alkali material with a rich nanoporous structure, which is recorded as: PDVB-vim-0.5, and the specific surface area of the obtained material is 700m 2 / g, the pore volume is 1.44cm 3 / g.

Embodiment 3

[0032] Embodiment 3: Synthetic polyimidazole functionalized nanoporous solid alkali material

[0033] Disperse 0.070 g of azobisisobutyronitrile in 30 ml of DMSO, then add 2.2 ml of divinylbenzene and 1.38 ml of vinylimidazole functional monomers, stir at room temperature for 3 hours, heat the solvent at 180°C for 24 hours in a kettle, and open Cover, volatilize the solvent, you can get a solid alkali material with rich nanoporous structure, recorded as: PDVB-vim-1.0, the specific surface area is 500m 2 / g, the pore volume is 1.14cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com