Composite flame-retardant smoke suppressor

A technology of compound flame retardant and smoke suppressant, applied in the field of flame retardant additives, can solve the problems of poor light resistance, generate more toxic products, etc., and achieve the effect of reducing combustion and smoke releasing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Composite flame retardant smoke suppressant is composed of: 40% magnesium hydroxide, 10% aluminum hypophosphite, 10% aluminum hydroxide, 10% microporous silica powder, 10% zinc borate, 10% magnesium aluminum hydrotalcite, 5% Smoke suppression catalyst, 3% highly active magnesium oxide, 2% coating agent compounded.

Embodiment 2

[0025] Composite flame retardant smoke suppressant is composed of: 30% magnesium hydroxide, 12% aluminum hypophosphite, 12% aluminum hydroxide, 10% microporous silica powder, 12% zinc borate, 12% magnesium aluminum hydrotalcite, 6% Smoke suppression catalyst, compounded with 4% highly active magnesium oxide and 2% coating agent.

Embodiment 3

[0027] The composite flame retardant smoke suppressant is composed of: 20% magnesium hydroxide, 14% aluminum hypophosphite, 14% aluminum hydroxide, 10% microporous silica powder, 14% zinc borate, 14% magnesium aluminum hydrotalcite, 7% Smoke suppressing catalyst, compounded with 5% highly active magnesium oxide and 2% coating agent.

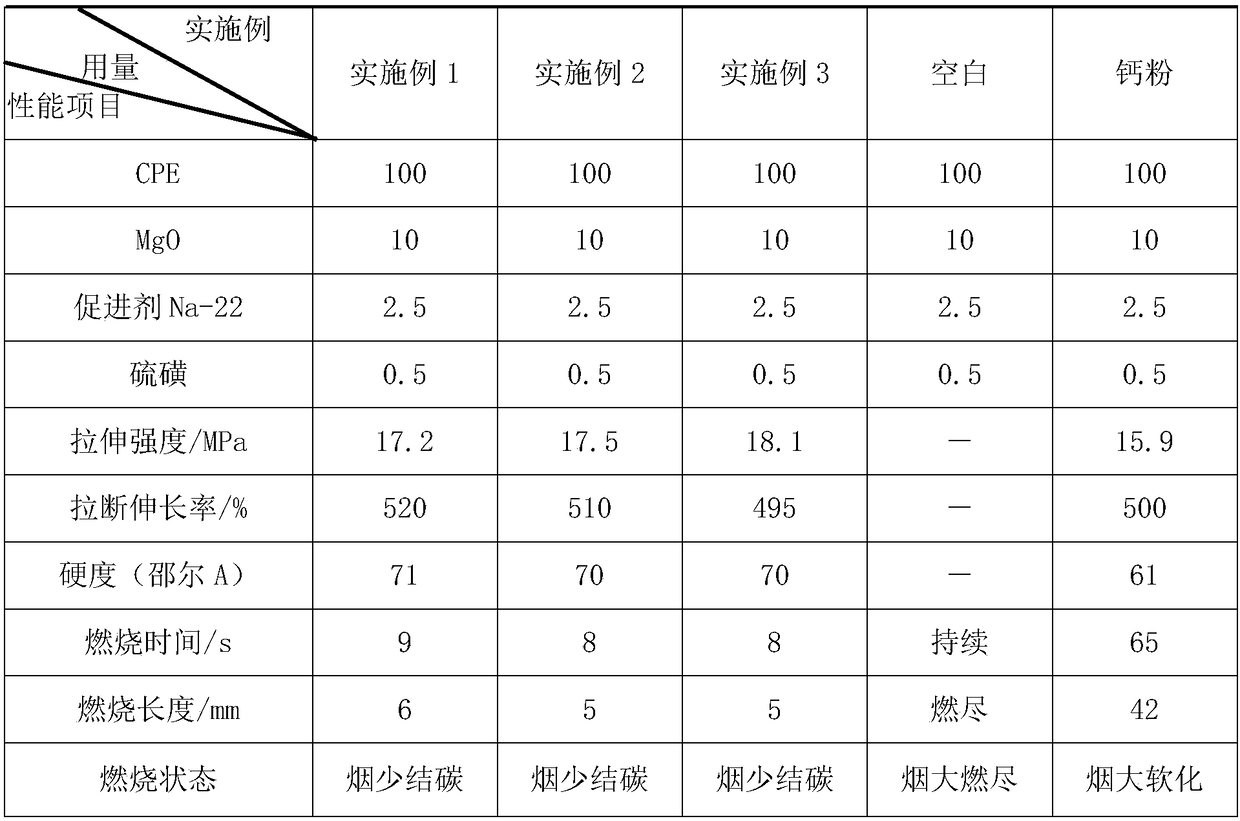

[0028] Table 1 shows the performance of composite flame retardants compared and tested by CPE vulcanizate (the addition of flame retardant powder or calcium powder is 30 parts).

[0029]

[0030] Table 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com