Low-VOC, low-odor environment-friendly PVC edge sealing strip material and preparation method thereof

An edge banding, low-odor technology, applied in the field of environmentally friendly PVC edge banding materials and their preparation, can solve the problems of complex PVC formulations, the risk of analysis, and many production processes, so as to reduce VOC and odor emissions, The effect of reducing decomposition and reducing decomposition products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

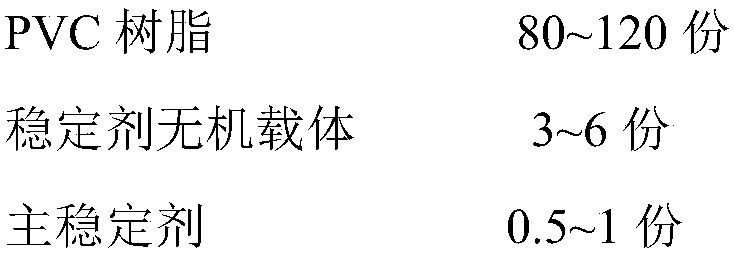

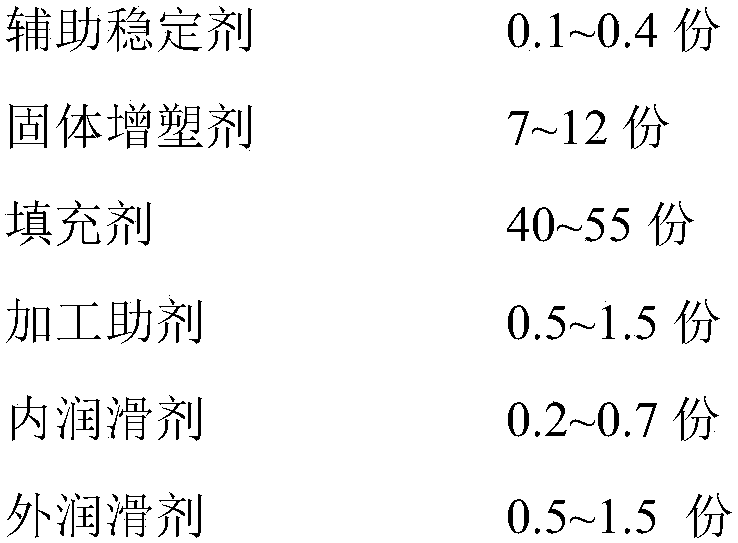

Method used

Image

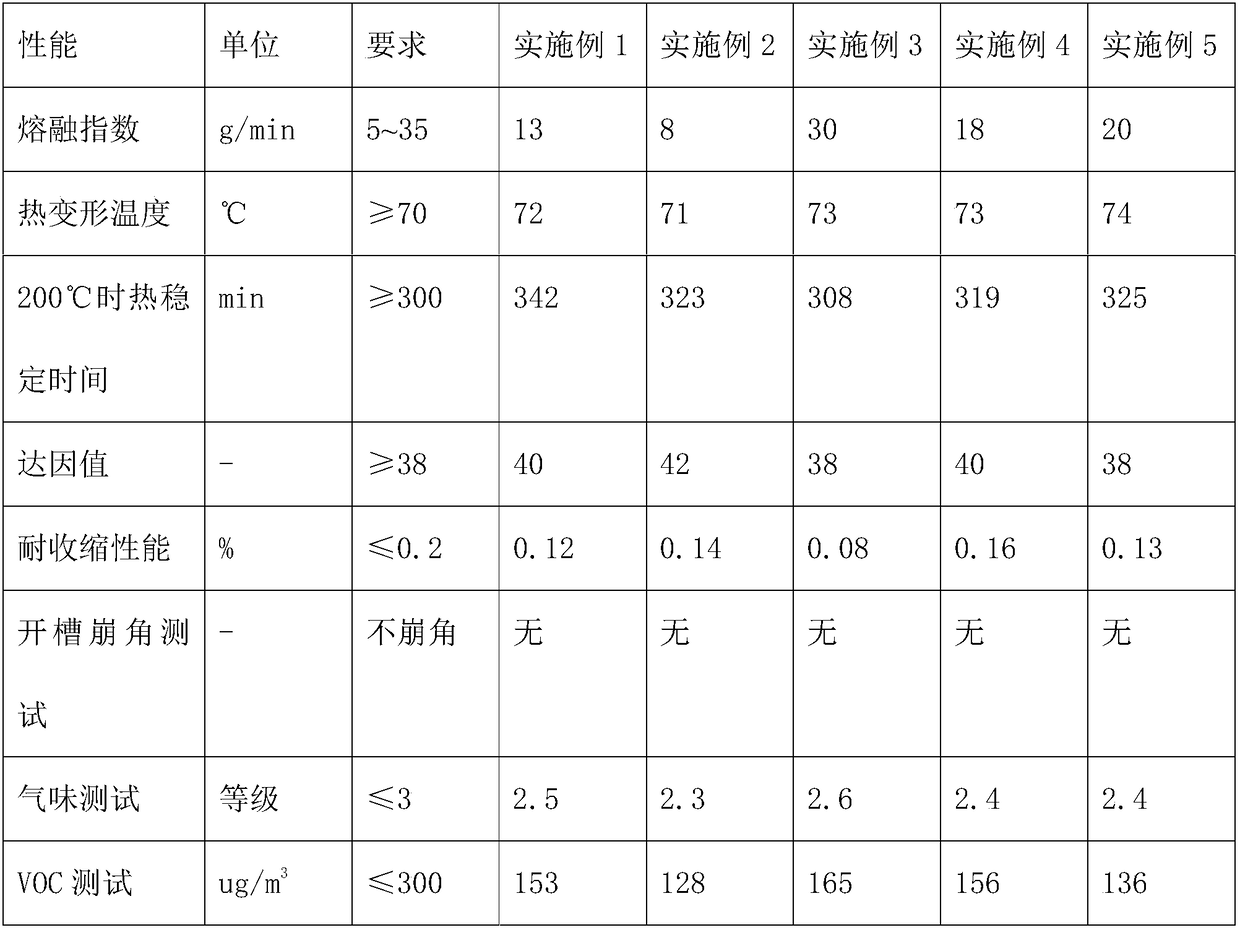

Examples

Embodiment 1

[0035] The preparation method of a kind of low-VOC, low-odor environment-friendly PVC edge banding material in the present embodiment comprises the following steps,

[0036] (1) Weigh the following raw materials: PVC resin 590g, stabilizer inorganic carrier 29g, main stabilizer 4g, auxiliary stabilizer 1g, solid plasticizer 59g, filler 30g, processing aid 6g, internal lubricant 3g, 6g of external lubricant. In fact, pure PVC polymers do not have any odor. The odor of PVC resin powder mainly depends on whether the post-treatments such as monomer removal and drying after polymerization can remove the monomer and the auxiliary agent added during the polymerization process. Volatile small molecular substances such as raw materials are removed. These volatile small molecular substances have a relatively large odor. It can be seen from the above-mentioned selected auxiliary raw materials that the auxiliary raw materials in this embodiment are all high melting points and low volatilit...

Embodiment 2

[0052] The preparation method of a kind of low-VOC, low-odor environment-friendly PVC edge banding material in the present embodiment comprises the following steps,

[0053] (1) The raw materials of the following quality are weighed: PVC resin 600g, stabilizer inorganic carrier 30g, main stabilizer 7g, auxiliary stabilizer 5g, solid plasticizer 48g, filler 38g, processing aid 7g, internal lubricant 7g, 7g of external lubricant, wherein the degree of polymerization of the PVC resin is 900-1100, and the mass fraction of volatile matter of the PVC resin is 0.5%. In addition, the odor test of each of the above raw materials reaches level 3.

[0054] (2) Stir and mix the above-mentioned PVC resin, stabilizer inorganic carrier, main stabilizer, auxiliary stabilizer, processing aid, internal lubricant and external lubricant according to the formula amount, and heat up to 105°C while stirring, and the stirring speed Be 2500r / min, obtain the first mixture that mixes homogeneously;

[...

Embodiment 3

[0068] The preparation method of a kind of low-VOC, low-odor environment-friendly PVC edge banding material in the present embodiment comprises the following steps,

[0069] (1) The raw materials of following quality are weighed: PVC resin 500g, stabilizer inorganic carrier 25g, main stabilizer 5g, auxiliary stabilizer 2g, solid plasticizer 60g, filler 20g, processing aid 3g, internal lubricant 4g, 5g of external lubricant, wherein the degree of polymerization of the PVC resin is 900-1000, and the mass fraction of volatile matter of the PVC resin is 0.3%; in addition, the odor test of each of the above raw materials reaches level 3.

[0070] (2) Stir and mix the above-mentioned PVC resin, stabilizer inorganic carrier, main stabilizer, auxiliary stabilizer, processing aid, internal lubricant and external lubricant according to the formula quantity, and heat up to 110°C while stirring, and the stirring speed Be 2000r / min, obtain the first mixture that mixes homogeneously;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap