Laser cladding method, laser head, laser and cladding system for realizing laser cladding method

A laser cladding and laser technology, applied in metal material coating process, coating, etc., can solve the problems of inability to real-time on-line heat treatment, high heat input, deformation performance, etc., to improve laser processing efficiency, high degree of automation, Effect of Reducing Residual Stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

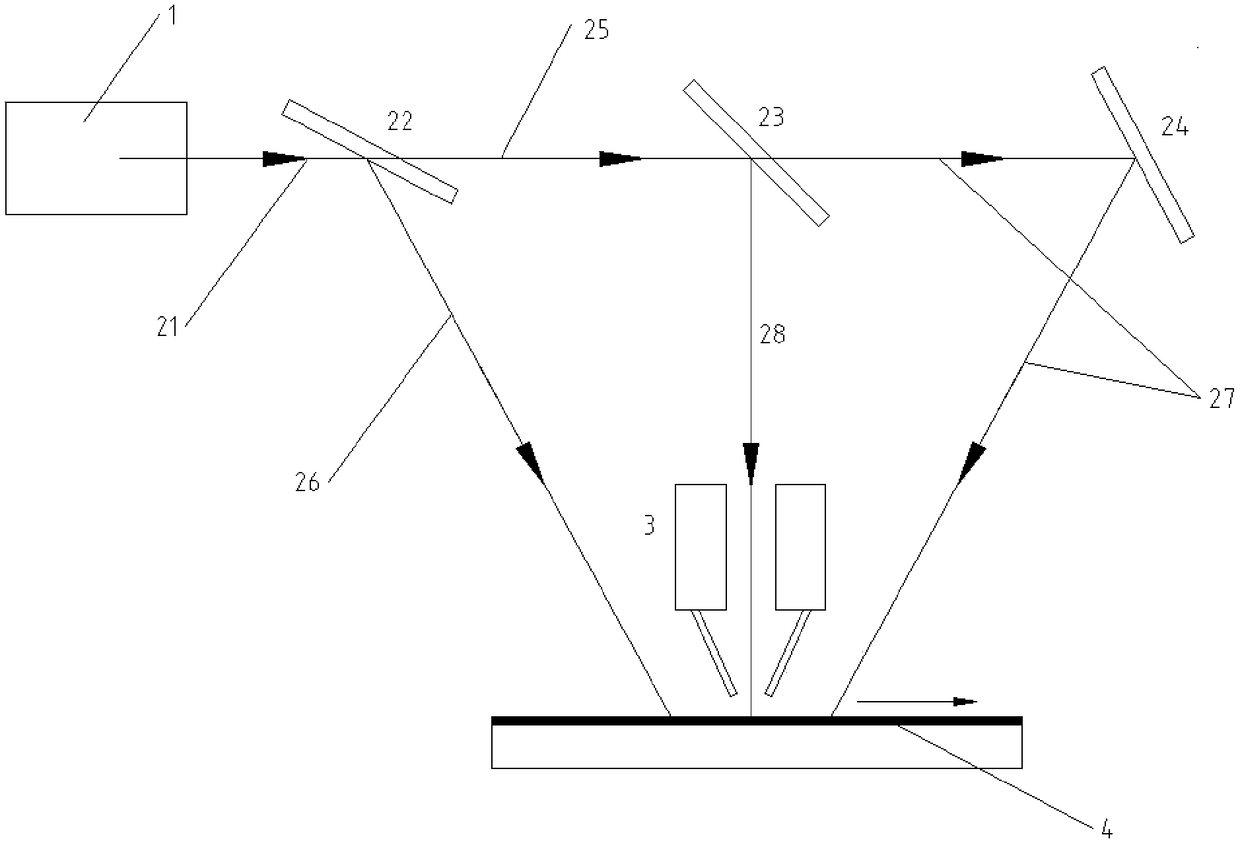

[0054] Such as figure 1 A laser cladding system shown includes a powder feeder 3 and a laser cladding laser. The laser cladding laser includes a laser body 1 and a laser head; the laser body 1 is a high-power semiconductor stack laser.

[0055] The laser head includes a first beam splitter 22, a second beam splitter 23 and a reflection mirror 24 arranged in sequence along the outgoing direction of the laser beam 21; the first beam splitter 22 and the second beam splitter 23 are flat beam splitters ; Mirror 24 is a plane mirror.

[0056] The first beam splitter 22 is used to divide the outgoing laser light 21 into the first transmitted laser light 25 and the first reflected preheating laser light 26; the second beam splitter 23 is used to divide the first transmitted laser light 25 into the second transmitted post-processing laser light 27 and the second reflection cladding laser 28; mirror 24 is used to change the direction of the second transmission post-processing laser 27; t...

Embodiment 2

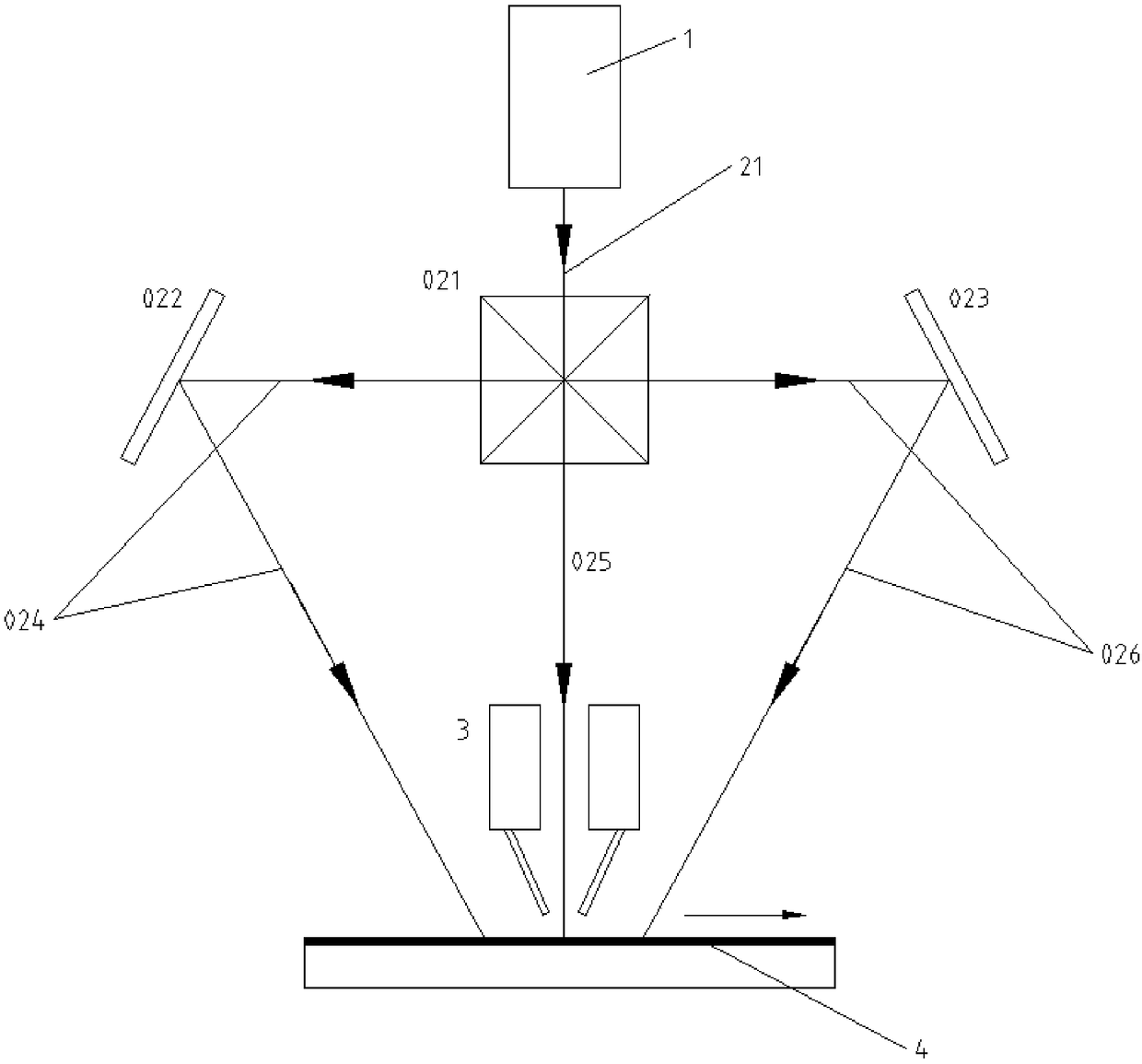

[0058] Such as figure 2 A laser cladding system shown includes a powder feeder 3 and a laser cladding laser. The laser cladding laser includes a laser body and a laser head; the laser body 1 is a high-power semiconductor stack laser.

[0059] The laser head includes a dichroic prism 021 arranged along the outgoing direction of the outgoing laser light 21, and a first mirror 022 and a second reflective mirror 023 arranged on both sides of the dichroic prism 021; the dichroic prism 021 divides the outgoing laser light 21 into prism preheating laser 024, prism cladding laser 025 and prism post-processing laser 026; prism cladding laser 025 directly irradiates the workpiece 4 to be processed along the exit direction of the outgoing laser 21; prism preheating laser 024 is reflected by the first reflector 022 and irradiates the workpiece to be processed 4. The prism post-processing laser 026 is reflected by the second reflector 023 and irradiates the workpiece 4 to be processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com