Method using nuclear magnetic resonance-displacement combined device to evaluate tight oil filling process

A technology for tight oil and displacement, which can be used in measurement devices, analysis by nuclear magnetic resonance, water resource assessment, etc., and can solve problems such as research gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

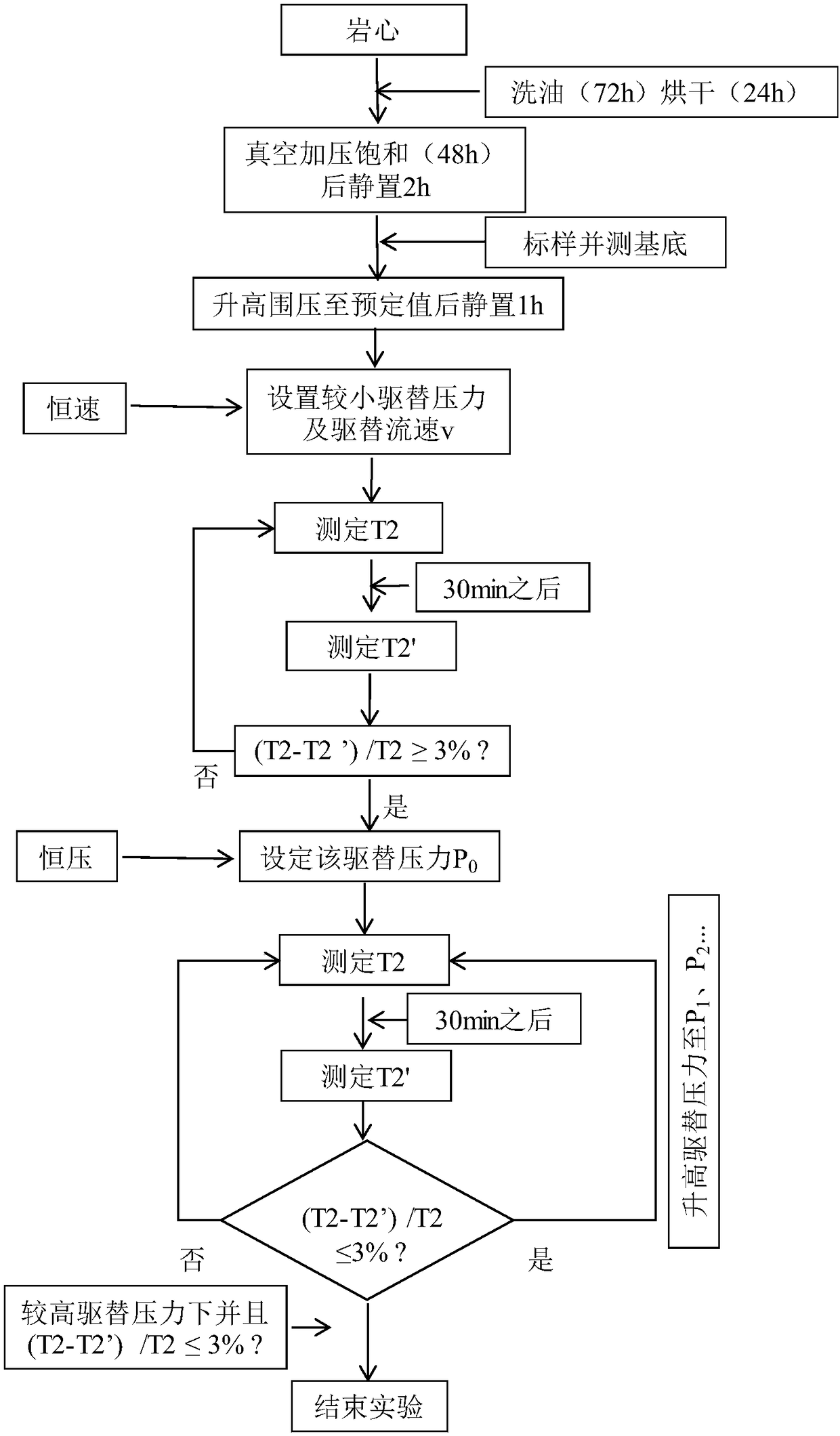

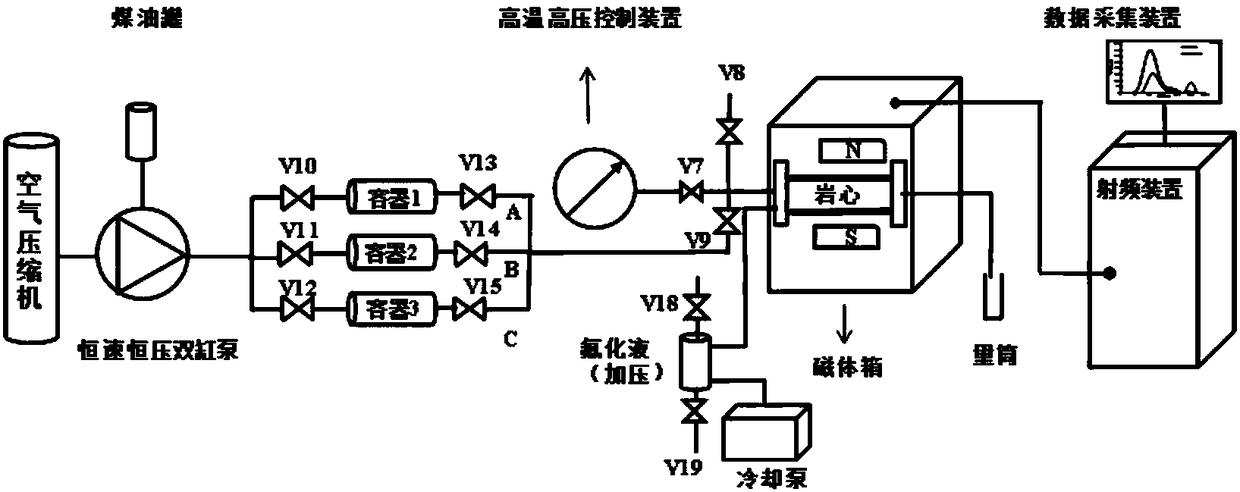

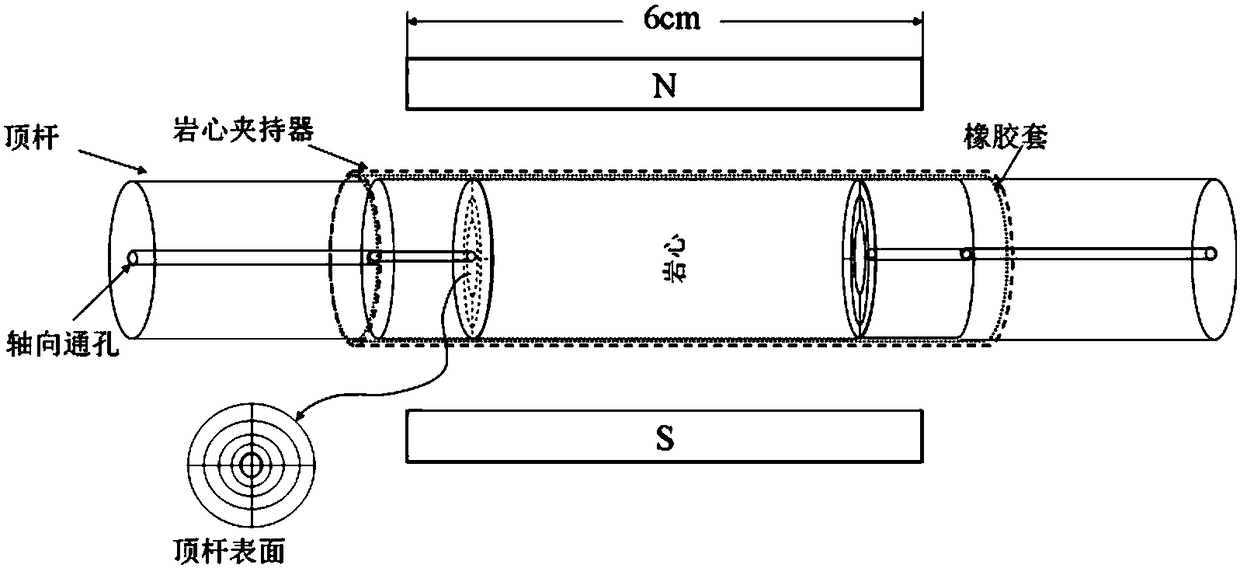

[0079] Such as figure 1 As shown, the present invention discloses a method for evaluating the charging process of tight oil by a nuclear magnetic-displacement combined device. The method uses fluorine oil without hydrogen signal to displace the core saturated with formation water (hydrogen signal) through nuclear magnetic Resonance test T 2 The continuous decrease of the signal amplitude of the spectrum reflects the changing process of the formation water in the pores being continuously displaced by fluorine oil. In the experiment, after allowing the fluorine oil to fully contact the core surface at a relatively small displacement pressure of 0.25 MPa, the first constant-rate displacement mode was adopted, and the NMR response was T 2 When the spectrum changes significantly, it is considered that the displacement is obviously proceeding, and then it is changed to the stage constant pressure mode until the NMR T 2 The signal amplitude in the spectrum no longer changes significant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com