Preparation and application of stainless steel mesh-loaded and carbon-coated tin nanostructure as negative electrode material for sodium-ion battery

A technology of sodium ion battery and stainless steel mesh, which is applied in nanotechnology for materials and surface science, electrode manufacturing, battery electrodes, etc., can solve problems such as unreported research work on preparation methods, and achieve improved size and enhanced electrical conductivity. , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

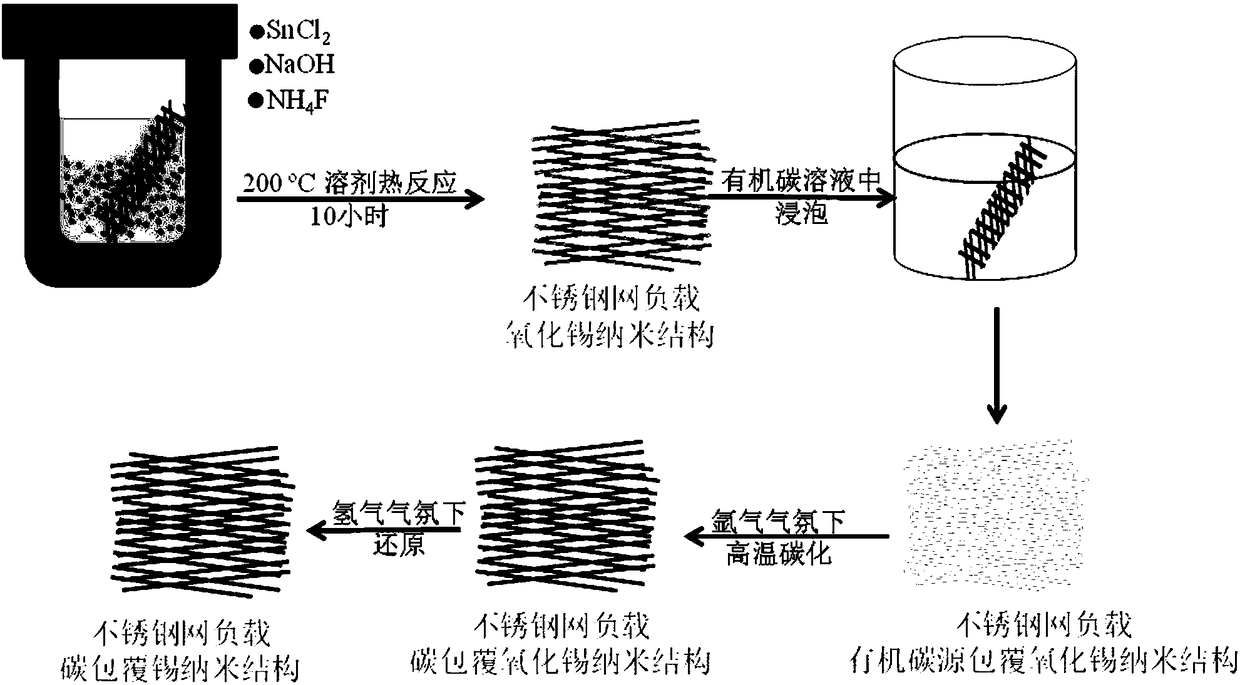

[0032] A preparation method of carbon-coated tin nanostructure supported by stainless steel mesh, comprising the following steps:

[0033] 1), under magnetic stirring, dissolve 0.625g of sodium hydroxide in 40ml of deionized water to obtain solution A;

[0034] 2), under magnetic stirring, add 0.47g tin chloride to above-mentioned A solution to obtain solution B;

[0035] 3), under magnetic stirring, add 0.05g of ammonium fluoride to solution B to obtain solution or emulsion C;

[0036] 4), transfer the solution C to a stainless steel reaction kettle, and place the pre-cleaned stainless steel mesh in the solution for hydrothermal reaction, clean the stainless steel mesh with deionized water and ethanol, and react at 200°C for 24 hours , the stainless steel mesh-loaded tin oxide nanostructure is obtained;

[0037] 5), the stainless steel net-loaded tin nanostructure obtained in 4) was placed in 3.6 g of glucose and 40 mL of deionized water, soaked in 180 ° C for 4 hours to ob...

Embodiment 2

[0043] A preparation method of carbon-coated tin nanostructure supported by stainless steel mesh, comprising the following steps:

[0044] 1), under magnetic stirring, 0.9375g of sodium hydroxide was dissolved in 40ml of deionized water to obtain solution A;

[0045] 2), under magnetic stirring, add 0.47g tin chloride to above-mentioned A solution to obtain solution B;

[0046] 3), under magnetic stirring, add 0.05g of ammonium fluoride to solution B to obtain solution or emulsion C;

[0047] 4), transfer the solution C to a stainless steel reaction kettle, and place the pre-cleaned stainless steel mesh in the solution for hydrothermal reaction, clean the stainless steel mesh with deionized water and ethanol, and react at 200°C for 24 hours , the stainless steel mesh-loaded tin oxide nanostructure is obtained;

[0048] 5), the stainless steel net-loaded tin nanostructure obtained in 4) was placed in 3.6 g of glucose and 40 mL of deionized water, soaked in 180 ° C for 4 hours...

Embodiment 3

[0054] A preparation method of carbon-coated tin nanostructure supported by stainless steel mesh, comprising the following steps:

[0055] 1), under magnetic stirring, dissolve 1.25g of sodium hydroxide in 40ml of deionized water to obtain solution A;

[0056] 2), under magnetic stirring, add 0.47g tin chloride to above-mentioned A solution to obtain solution B;

[0057] 3), under magnetic stirring, add 0.05g of ammonium fluoride to solution B to obtain solution or emulsion C;

[0058] 4), transfer the solution C to a stainless steel reaction kettle, and place the pre-cleaned stainless steel mesh in the solution for hydrothermal reaction, clean the stainless steel mesh with deionized water and ethanol, and react at 200°C for 24 hours , the stainless steel mesh-loaded tin oxide nanostructure is obtained;

[0059] 5), the stainless steel net-loaded tin nanostructure obtained in 4) was placed in 3.6 g of glucose and 40 mL of deionized water, soaked in 180 ° C for 4 hours to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com