Production method of dried Shixia longan

A production method and technology of dried longan, which are applied in the fields of food preservation, fruit and vegetable preservation, food science, etc., can solve the problems of sugar, nutrient loss, dull color of dried products, serious dehydration of dried longan, etc. Yellow-brown, soft and sweet effect on the palate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

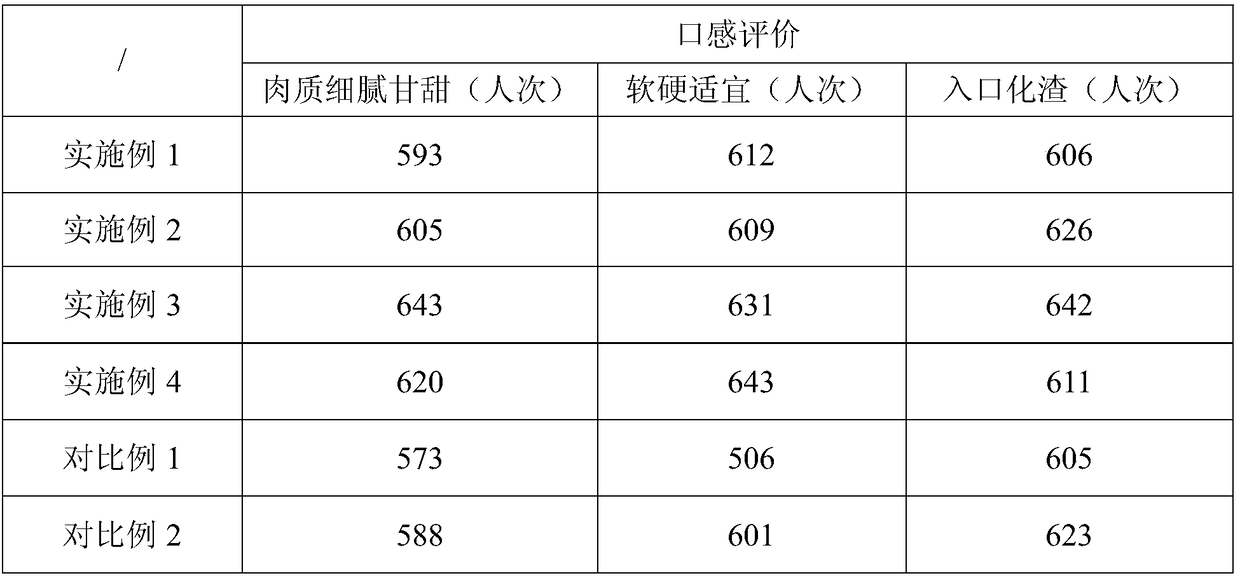

Examples

Embodiment 1

[0025] A method for making Shixia dried longan, comprising the following steps:

[0026] (1) Preparation of conditioning solution: 1. preparation of aloe extract: take 20 parts of aloe after washing and peeling, put it into a juice extractor, add 20 parts of water, squeeze for 10 min, filter and collect the filtrate to obtain the aloe extract; ②Preparation of licorice extract: wash 15 parts of licorice, put it in a pot, add 30 parts of water, cook for 30 minutes, filter and collect the filtrate to obtain the licorice extract; ③Take 20 parts of aloe extract and 15 parts of licorice extract , 15 parts of vitamin C, 20 parts of citric acid, and 30 parts of lemon juice are mixed evenly and set aside;

[0027] (2) material selection and shelling: select fresh, mature, longan without pests and diseases, and remove the longan shell;

[0028] (3) Finishing: put the longan pulp in step (2) into warm water at 50°C for rinsing for 30 seconds, remove it quickly and place it in an aqueous...

Embodiment 2

[0034] A method for making Shixia dried longan, comprising the following steps:

[0035] (1) Preparation of conditioning solution: 1. preparation of aloe extract: get 25 parts of aloe after washing and peeling, put it into a juice extractor, add 30 parts of water, squeeze for 15min, filter and collect the filtrate to obtain the aloe extract; ②Preparation of licorice extract: wash 20 parts of licorice, put them in a pot, add 45 parts of water, cook for 40 minutes, filter and collect the filtrate to obtain the licorice extract; ③Take 25 parts of aloe extract and 20 parts of licorice extract , 20 parts of vitamin C, 10 parts of citric acid, and 25 parts of lemon juice are mixed evenly and set aside;

[0036] (2) material selection and shelling: select fresh, mature, longan without pests and diseases, and remove the longan shell;

[0037] (3) Finishing: Put the longan pulp in step (2) into warm water at 52°C for 28 seconds, quickly remove it and soak it in an aqueous solution at ...

Embodiment 3

[0043] A method for making Shixia dried longan, comprising the following steps:

[0044] (1) Prepare conditioning solution: 1. prepare aloe extract: get 30 parts of aloe after washing and peeling, put it into a juicer, add 45 parts of water, squeeze for 15min, filter and collect the filtrate to obtain the aloe extract; ②Preparation of licorice extract: wash 20 parts of licorice, put them in a pot, add 50 parts of water, cook for 50 minutes, filter and collect the filtrate to obtain the licorice extract; ③take 30 parts of aloe extract and 20 parts of licorice extract , 15 parts of vitamin C, 15 parts of citric acid, and 20 parts of lemon juice are mixed evenly and set aside;

[0045] (2) material selection and shelling: select fresh, mature, longan without pests and diseases, and remove the longan shell;

[0046] (3) Finishing: Put the longan pulp in step (2) into warm water at 55°C for 25 seconds, quickly remove it and soak it in an aqueous solution at 3-4°C for 25 minutes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com