Hexagonal ferrite material with high anisotropy and low ferromagnetic resonance line width and preparation method

A ferromagnetic resonance line and hexagonal ferrite technology, which is applied in the field of ferrite material preparation, can solve the problems of unpublished ferromagnetic resonance line width and anisotropy parameters, and achieve the effect of increasing the working frequency band and reducing the insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

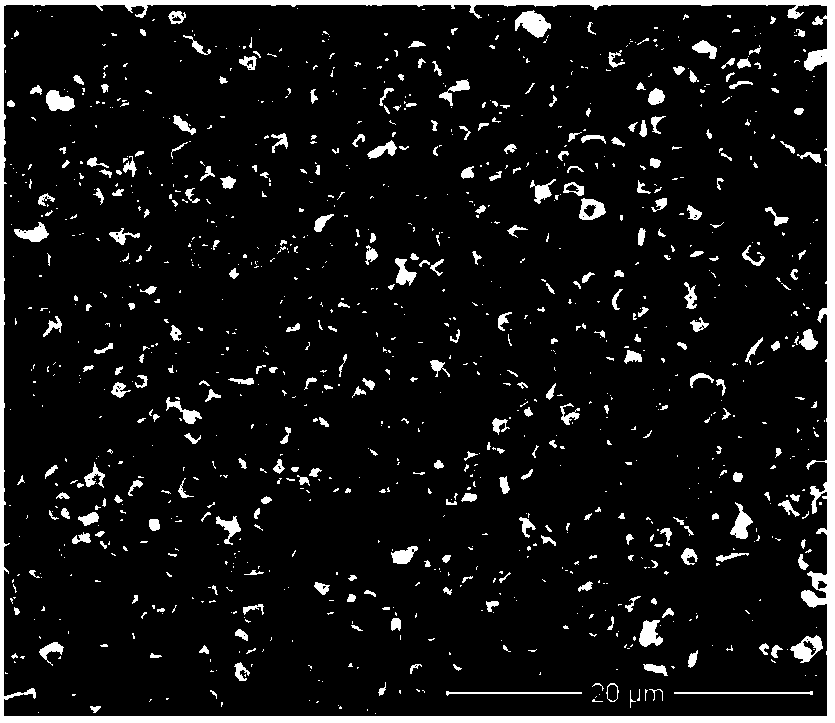

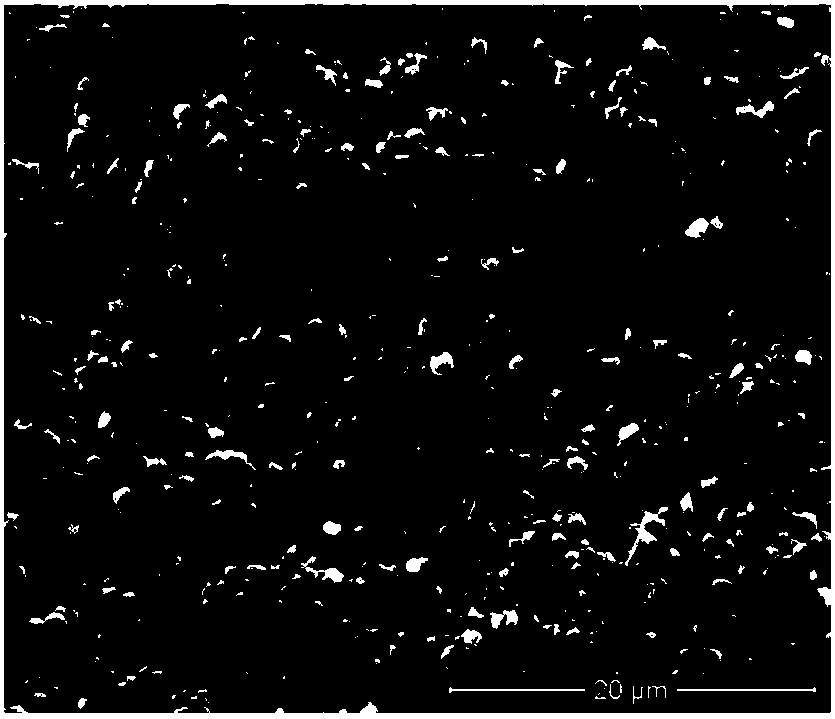

Image

Examples

preparation example Construction

[0048] The main component of the hexagonal ferrite material with high anisotropy and low ferromagnetic resonance line width of the present invention is calculated as an oxide by mole percentage, and the dopant component is calculated by weight percentage as an oxide. M type hexagonal ferrite material of the present invention and preparation method thereof, comprises the following steps:

[0049] 1. Main ingredient formula

[0050] Using 67.0~75.0mol% Fe 2 o 3 , 0.5~7.5mol%SrCO 3 , 0.5~7.5mol% BaCO 3 , 3.5~6.5mol%Co 2 o 3 , 3.5~11.5mol%La 2 o 3 , 8.5~13.5mol% CuO;

[0051] 2. One ball milling

[0052] Mix the above powders evenly in a ball mill for 20-26 hours;

[0053] 3. Pre-burning

[0054] Dry the ball mill material obtained in step 2, and pre-fire it in a furnace at 1000-1150°C for 3-6 hours;

[0055] 4. Doping

[0056] Add the following dopant to the powder obtained in step 3 by weight ratio: 0.5-2.0wt% Bi 2 o 3 , 0.15~1.0wt%B 2 o 3 , 0.02~0.32wt% CaCO 3...

Embodiment 1~4

[0070] Embodiments 1-4: A method for preparing a hexagonal ferrite material with high anisotropy and low ferromagnetic resonance linewidth, comprising the following steps:

[0071] Embodiment 1~4:

[0072] 1. Formula

[0073] Embodiment 1~4 master formula sees the following table:

[0074]

[0075] 2. One ball milling

[0076] Mix the above-mentioned powders evenly in a ball mill for 25 hours;

[0077] 3. Pre-burning

[0078] Dry the ball mill material obtained in step 2, and pre-fire it in a furnace at 1020°C for 5.5 hours;

[0079] 4. Doping

[0080] Add the following dopant by weight ratio to the powder obtained in step 3: 1.25wt% Bi 2 o 3 , 0.75wt% B 2 o 3 , 0.08wt% CaCO 3 , 0.04wt% SiO 2 , embodiment 1~4 adds ISOBAM (isobutylene-maleic anhydride copolymer) according to the table;

[0081]

[0082] 5. Secondary ball milling

[0083] Mill the ingredient powder in step 4 in a ball mill for 10 hours, and the particle size of the powder is controlled between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com