Preparation method of high-nitrogen modified ammonium nitrate explosive crystal doped with 2D conjugated structure

A technology of ammonium nitrate explosives and two-dimensional conjugation, which is applied in explosives processing equipment, explosives, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., which can solve the problems of long time, unfavorable large-scale use, and synthesis cost Advanced problems, to achieve the effect of high yield, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

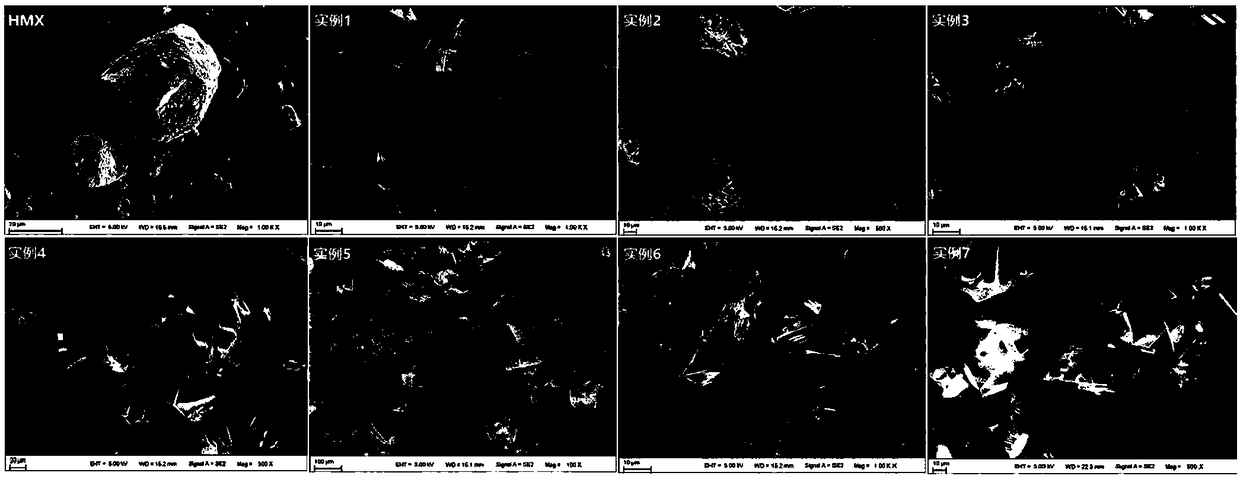

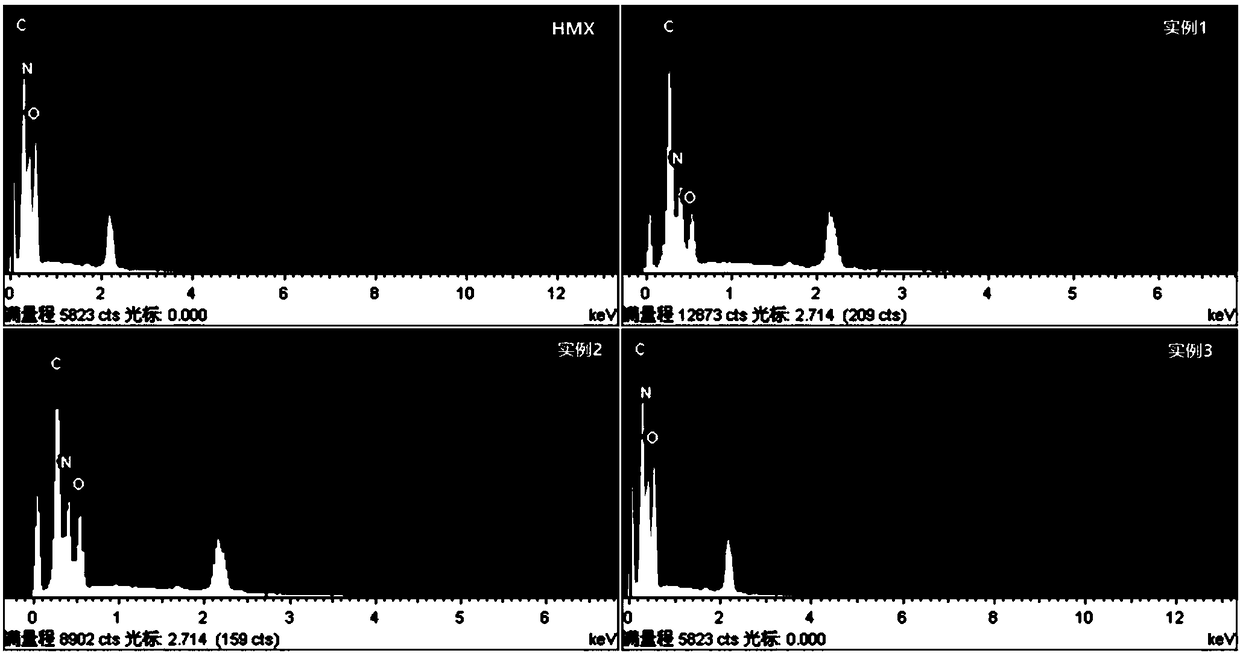

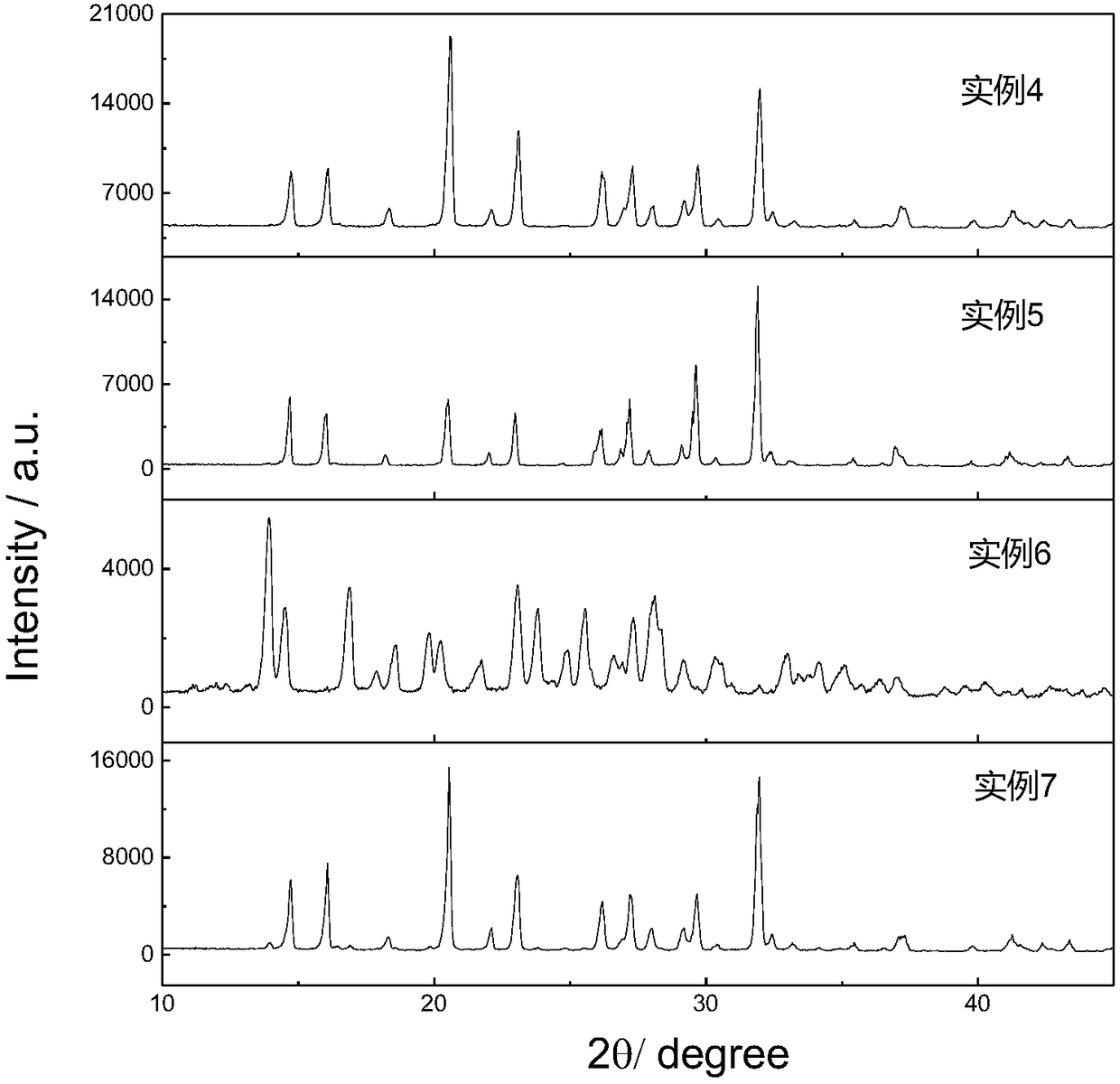

example 1

[0035] A preparation method of a two-dimensional conjugated structure doped modified ammonium nitrate explosive crystal, comprising the following process steps:

[0036]Dissolution of triaminoguanidine nitrate: Weigh 0.32g triaminoguanidine nitrate and add to 20ml dimethyl sulfoxide (also can be other solvents that can dissolve triaminoguanidine nitrate, such as thionyl chloride, diphenyl sulfone), heated to 70°C in a water bath (oil bath, electric heating), and magnetically stirred (rotor speed 150r / min) for 30min to completely dissolve triaminoguanidine nitrate.

[0037] Formation of high-nitrogen two-dimensional conjugated structure materials: add 0.72g glyoxal (or other solvents that can form a two-dimensional conjugated structure with triaminoguanidine nitrate, such as formaldehyde, glycerol), heat and stir for 1h to obtain a two-dimensional conjugated structure.

[0038] Dissolution of ammonium nitrate explosives: take by weighing Octokine (also can be other ammonium ni...

example 2

[0047] A method for preparing a two-dimensional conjugated structure doped modified ammonium nitrate explosive crystal, comprising the following process steps:

[0048] The dissolution of triaminoguanidine nitrate: take 0.51g triaminoguanidine nitrate and join in 15ml dimethyl sulfoxide (or other solvents that can dissolve triaminoguanidine nitrate), normal temperature (or water bath, oil bath, electric heating ) Stir for a period of time (30min in this example) to completely dissolve triaminoguanidine nitrate.

[0049] Dissolution of ammonium nitrate explosive: Weigh 2.66g of octogen (the molar ratio of triaminoguanidine nitrate to octogen is 1:3) and add it to the dissolved triaminoguanidine nitrate solution, stir with a magnetic stirrer After 30 min, the solution turned orange red.

[0050] The generation of high-nitrogen two-dimensional conjugated structure material: the solution oil bath heating (or electric heating) that is dissolved with triaminoguanidine nitrate and a...

example 3

[0059] A method for preparing a two-dimensional conjugated structure doped modified ammonium nitrate explosive crystal, comprising the following process steps:

[0060] The dissolution of triaminoguanidine nitrate: take 0.24g triaminoguanidine nitrate and join in 15ml dimethyl sulfoxide (or other solvents that can dissolve triaminoguanidine nitrate), water bath (also can be oil bath or electric heating ) Stir at 70°C for a period of time (30min in this example) to completely dissolve triaminoguanidine nitrate.

[0061] The generation of high-nitrogen two-dimensional conjugated structure material: heating the triaminoguanidine nitrate solution in a water bath (oil bath or electric heating), keeping the temperature at 70°C, adding 0.28g glyoxal (or other substances that can react with triaminoguanidine nitrate A material forming a two-dimensional structure), heated and stirred for a period of time (1h in this example) to obtain a two-dimensional conjugated structure.

[0062] D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com