Acrylamide copolymer, and preparation method and application thereof

A technology of acrylamide copolymer and acrylamide copolymerization, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of small molecular weight of the product, limitation of polymer use, cumbersome process operation, etc., and achieve good water solubility, The effect of low residual monomer content and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

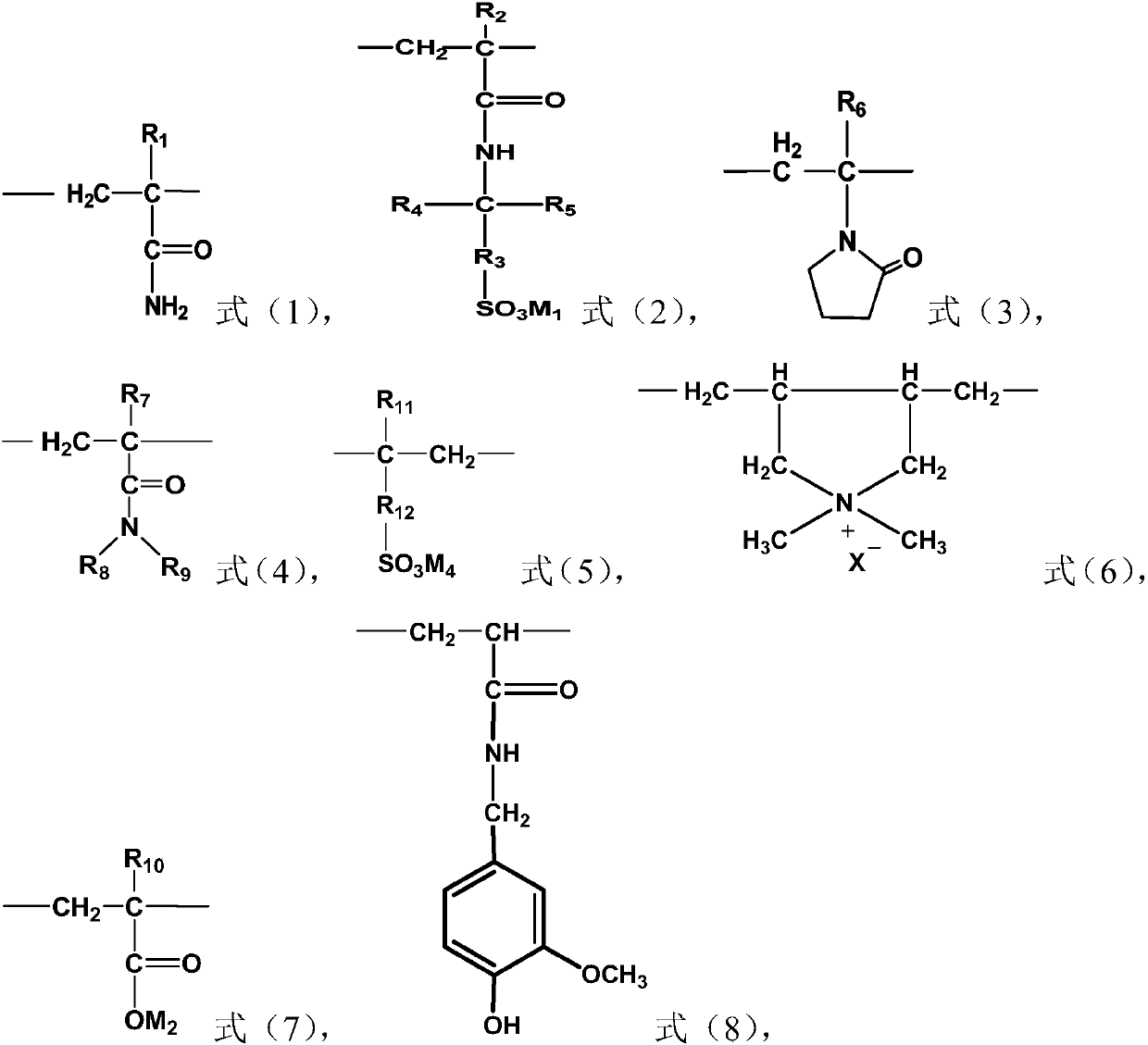

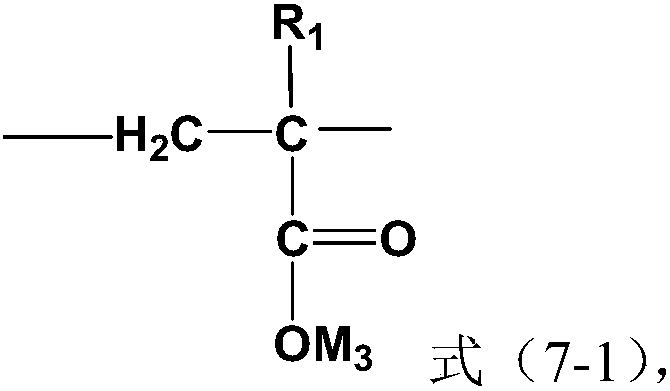

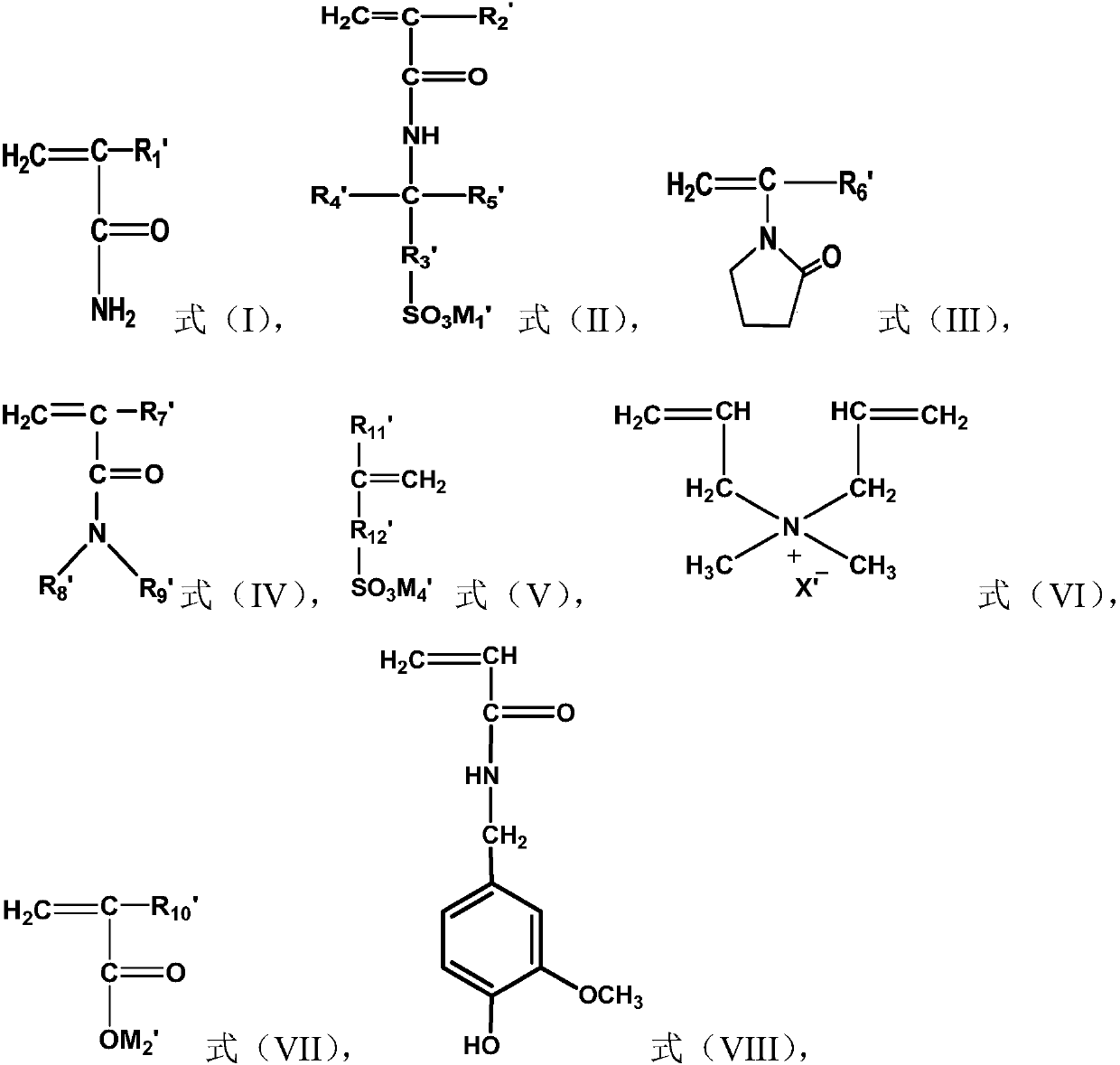

[0038] The method for preparing an acrylamide copolymer provided by the present invention comprises: under solution polymerization conditions and in the presence of an initiator, polymerize (a) monomer mixture in water, wherein the monomer mixture contains monomer E, monomer F and monomer G, said monomer E is a monomer having a structure shown in formula (I), and said monomer F is a monomer having a structure shown in formula (II)-formula (VII) At least one of the above, the monomer G is a monomer having a structure shown in formula (VIII), and the weight ratio of the monomer E, the monomer F and the monomer G is 1:0.001- 10: 0.001-10, more preferably 1: 0.01-1.5: 0.01-0.2, most preferably 1: 0.01-1: 0.01-0.1; the solution polymerization conditions make the viscosity-average molecular weight of the polymer obtained after the polymerization reaction is 1 million-40 million, preferably 20 million-30 million,

[0039]

[0040] Among them, R 1 ’, R 2 ’, R 6 ’, R 7 ’, R 10...

Embodiment approach

[0078] According to a preferred embodiment of the present invention, the photoinitiator also contains a water-soluble azo-based initiator, and the weight ratio of the organic amine, the water-soluble compound, and the water-soluble azo-based initiator is 1: 0.1-10: 0.1-10, the organic amine is N,N,N',N'-tetramethylethylenediamine, and the water-soluble azo initiator is 2,2'-azobis(2 -amidinopropane) dihydrochloride. Using the photoinitiator in this preferred embodiment as an initiator can further improve the polymerization efficiency.

[0079]According to a preferred embodiment of the present invention, the photoinitiator consists of the above components. Generally, each component in the photoinitiator used in the present invention is stored independently, and added to the polymerization reaction system separately when used.

[0080] According to the present invention, the conditions of the solution polymerization reaction may be conventional conditions in the art. For exam...

Embodiment 1

[0104] This embodiment is used to illustrate the preparation method of the acrylamide copolymer provided by the present invention

[0105] In the beaker, add 1000 grams of acrylamide (AM), 10 grams of 2-acrylamido-2-methylpropanesulfonic acid and 10 grams of the active functional monomer of the structure shown in formula (VIII), 4080 grams of deionized water, While stirring, control the temperature of the solution at 5°C with chilled brine, and adjust the pH to 7 by adding sodium hydroxide. Transfer the monomer solution to a polymerization bottle, add 10.2 mg of water-soluble azo initiator 2,2'-azobis(2-amidinopropane) dihydrochloride and 10.2 mg of amine N,N,N', For N'-tetramethylethylenediamine, deoxygenate with high-purity nitrogen gas for 0.5 hour, add 10.2 mg of sodium bisulfite and 10.2 mg of ammonium persulfate, continue nitrogen gas flow until the thermocouple in the polymerization bottle starts to heat up, and the reaction time is 8 hours. The colloid is taken out an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com