Preparation method of high-toughness anti-aging cable insulation material

A cable insulation and anti-aging technology, which is applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve problems such as aging resistance, high temperature resistance, elasticity and toughness that cannot meet the requirements of society, and short service life of cable materials. To achieve the effect of improving toughness and elasticity, and improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

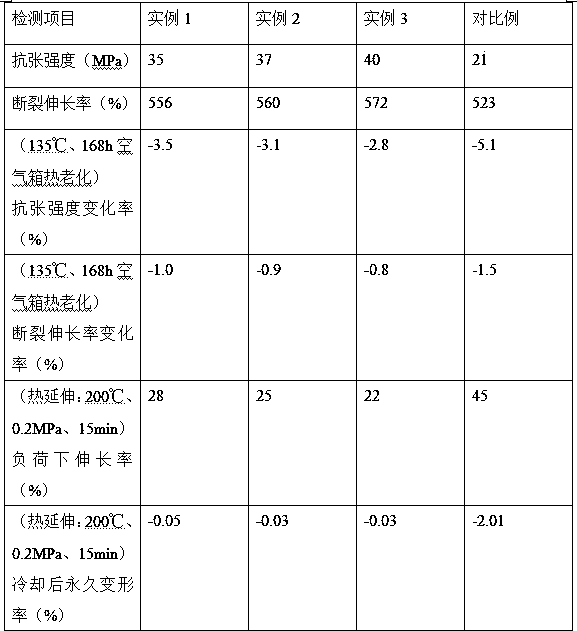

Examples

example 1

[0024] Weigh fresh pork bones and put them into a pulverizer for crushing for 1 hour. Sorting to obtain pork bone fragments with a particle size of 1mm, spread the obtained pork bone fragments on a stainless steel tray, and place the stainless steel tray at a temperature of 30°C 1. In a greenhouse with a relative air humidity of 70%, let it stand for moldy treatment for 3 days to obtain moldy pig bone fragments; transfer the obtained moldy pig bone fragments into a fermenter, and then add moldy pig bone fragments to the fermenter Deionized water of equal quality, stirred evenly, sealed the fermenter, sealed and fermented at a temperature of 38°C for 7 days, filtered and separated to obtain the filter residue after fermentation; the fermentation filter residue, tea polyphenol solution with a mass fraction of 40% and honey were pressed The mass ratio is 1:10:2, and the ultrasonic oscillator is used to ultrasonically oscillate and impregnate at a frequency of 25kHz for 30min, and ...

example 2

[0026]Weigh fresh pork bones and put them into a pulverizer for crushing for 1.5 hours, and sort to obtain pork bone fragments with a particle size of 2mm, spread the obtained pork bone fragments on a stainless steel tray, and place the stainless steel tray at a temperature of 33 ℃, air relative humidity is 75% in the greenhouse, stand moldy treatment for 4 days, obtain moldy pork bone fragments; transfer the obtained moldy pig bone fragments into the fermenter, then add moldy pork bone fragments into the fermenter Deionized water of equal mass, stirred evenly, sealed the fermenter, sealed and fermented at 40°C for 8 days, and filtered and separated to obtain the filter residue after fermentation; the fermentation filter residue, tea polyphenol solution with a mass fraction of 40% and honey Mix according to the mass ratio of 1:10:2, use an ultrasonic oscillator to ultrasonically oscillate at a frequency of 28kHz and impregnate for 35min, filter and separate to obtain the impreg...

example 3

[0028] Weigh the fresh pork bone and put it into a pulverizer for 2 hours, and sort the pork bone fragments with a particle size of 3mm, spread the obtained pork bone fragments on a stainless steel tray, and place the stainless steel tray at a temperature of 35°C 1. In a greenhouse with a relative air humidity of 80%, let it stand for moldy treatment for 5 days to obtain moldy pig bone fragments; transfer the obtained moldy pig bone fragments into a fermenter, and then add moldy pig bone fragments to the fermenter Deionized water of equal quality, stirred evenly, sealed the fermenter, sealed and fermented at 45°C for 9 days, filtered and separated to obtain the filter residue after fermentation; the fermentation filter residue, tea polyphenol solution with a mass fraction of 40% and honey were pressed The mass ratio is 1:10:2, and the ultrasonic oscillator is used to oscillate and impregnate for 40min at a frequency of 30kHz, and filter and separate to obtain the impregnated fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com