Drafting roller for special polyethylene fibers, drafting machine and drafting device

A polyethylene fiber and drafting roller technology, which is applied in the fields of drafting rollers, drafting machines and drafting devices, can solve the problems of volatilization of extractant to the production workshop and unstable quality of primary fibers, so as to reduce the number of labor and labor Strength, improving the yield and quality of products, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

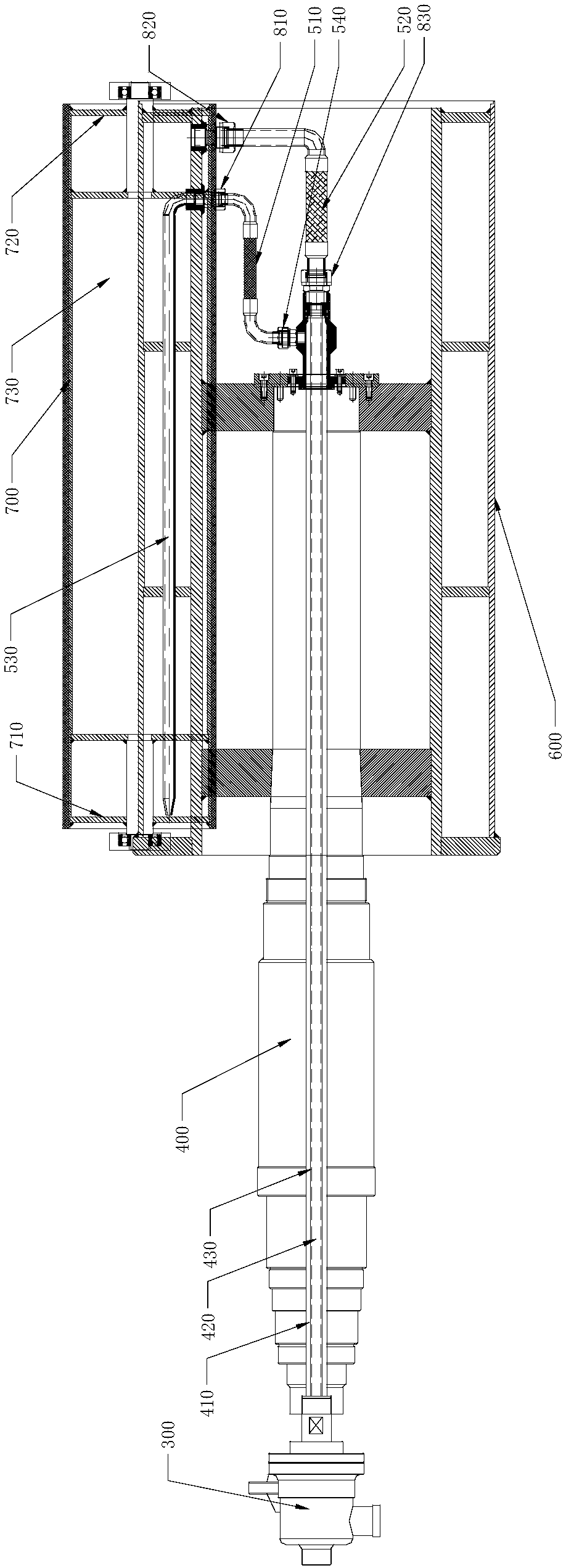

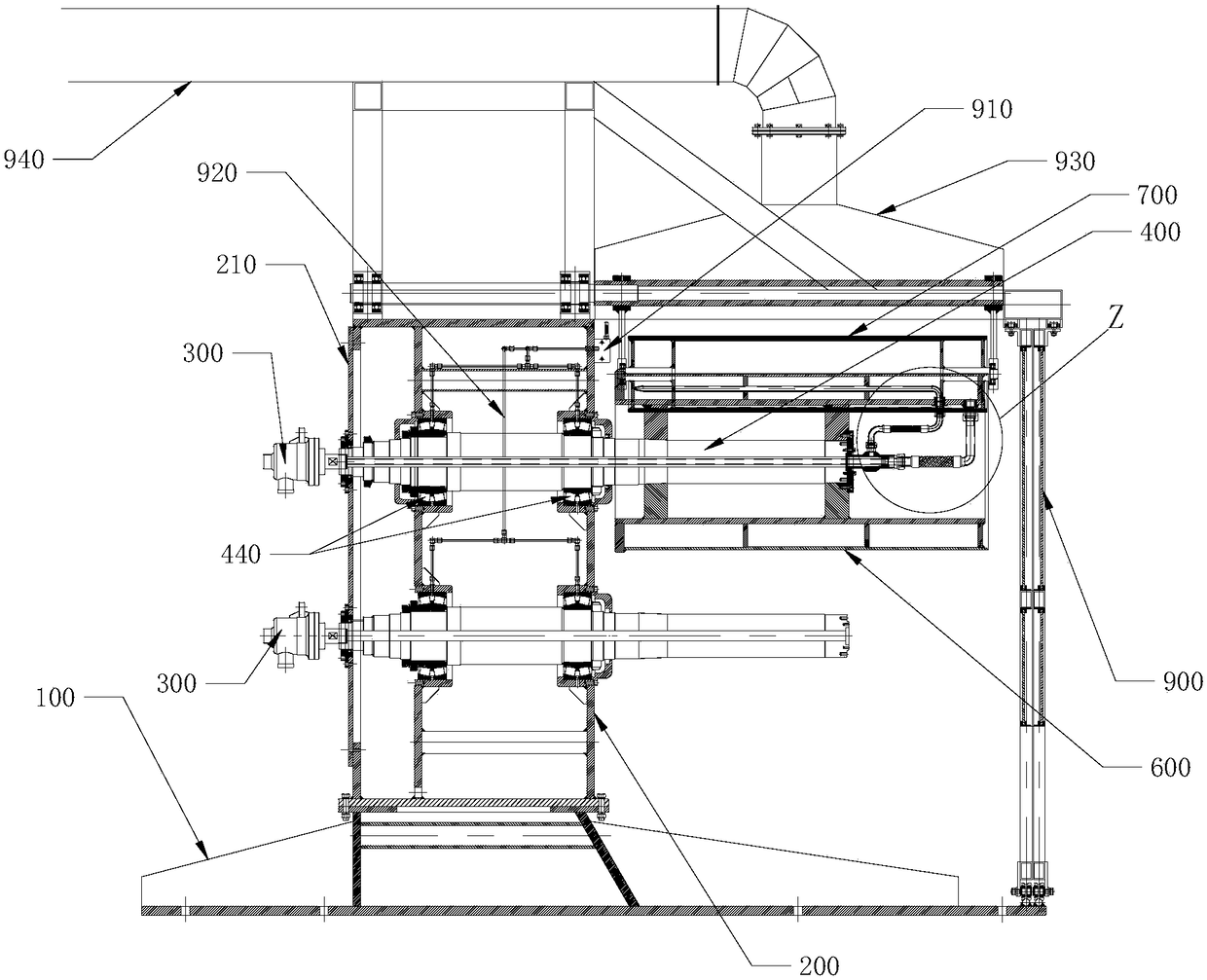

[0039] On the one hand, this embodiment provides a drafting roll for special polyethylene fibers, see figure 1 , Which includes a rotating shaft 400, a roller body 600, a jacketed roller 700 and a heat conducting medium tube, in which:

[0040] The rotating shaft 400 is provided with a first channel 410 and a second channel 420. The first channel 410 is cylindrical, and the second channel 420 is a circular cylindrical cross section. The axis of the first channel 410 and the second channel 420 The axes of both coincide with the axis of the rotating shaft 400. The independent first channel 410 and the second channel 420 provide an inlet and a return channel for the heat transfer medium, and the first channel 410, the second channel 420, and the rotating shaft 400 The axes of the three are coincident, so that the first channel 410 and the cross-sectional shape of the second channel 420 remain fixed when the three are rotated synchronously, which provides conditions for docking the pi...

Embodiment 2

[0059] On the basis of Example 1, the inventor found that since the outlet of the first channel 410 and the inlet of the second channel 420 are located at the same end of the rotating shaft 400, the horizontal position between the two is relatively small, such as when the medium flows directly. The same end of the cavity 430 is provided with a medium inlet and a medium outlet so that the left side of the medium inlet (such as figure 1 The fluidity of the heat transfer medium in the middle left direction is the left side) is very small, resulting in uneven temperature in the medium flow cavity 430. Therefore, the medium pipe 530 is fixed in the acrobatic medium flow cavity 430, and the first end of the medium pipe 530 is connected to Medium inlet, the second end of the medium conduit 530 extends to the first end 710 of the medium flow chamber 430 and is spaced from the end cap of the first end 710. The medium inlet and the medium outlet are both arranged in the second end of the m...

Embodiment 3

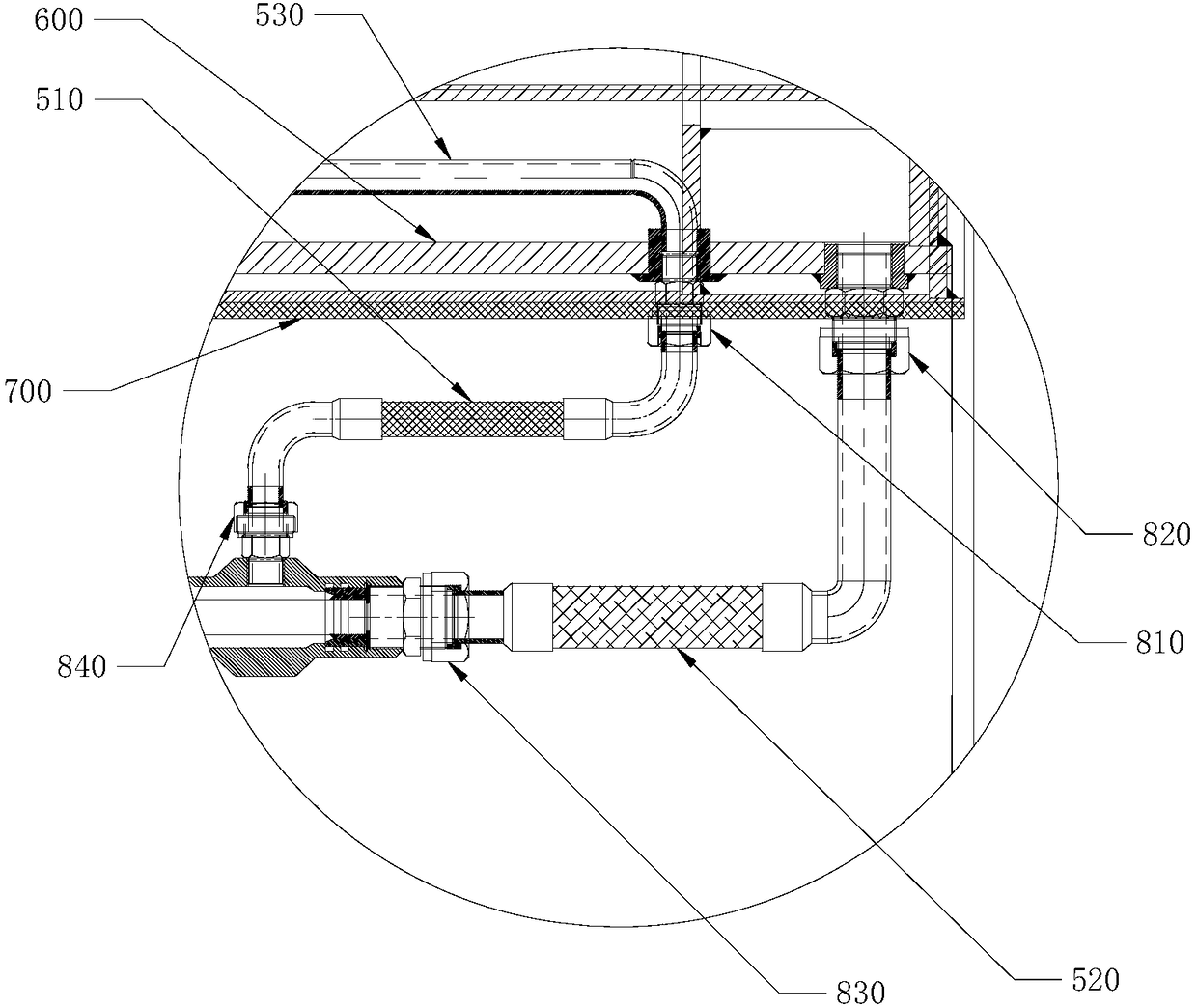

[0064] On the basis of Embodiment 1 or Embodiment 2, a connection method of the first channel 410 and the medium inlet, and the second channel 420 and the medium outlet is as follows: the first channel 410 is connected to the medium inlet through the medium inlet pipe 510, and / Alternatively, the second channel 420 is connected to the medium outlet through the medium return pipe 520.

[0065] When the first channel 410 is connected to the medium inlet through the medium inlet pipe 510, and the second channel 420 is connected to the medium outlet through the medium return pipe 520;

[0066] Both the medium inlet pipe 510 and the medium return pipe 520 are hoses, which are easy to install and disassemble, which is convenient for later replacement. At the same time, the hose itself can be bent to save space;

[0067] The medium return pipe 520 and the second channel 420, the medium return pipe 520 and the medium outlet, the medium inlet pipe 510 and the medium inlet respectively pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com