Low alkalinity and high selectivity copper-molybdenum flotation collector and preparation method thereof

A high-selectivity, low-alkalinity technology, applied in flotation, solid separation, etc., can solve problems such as poor recovery rate of molybdenum, difficulty in adding lime, poor floatability of molybdenum, etc., to achieve easy Effect of sorting, high promotional value and application prospect, low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

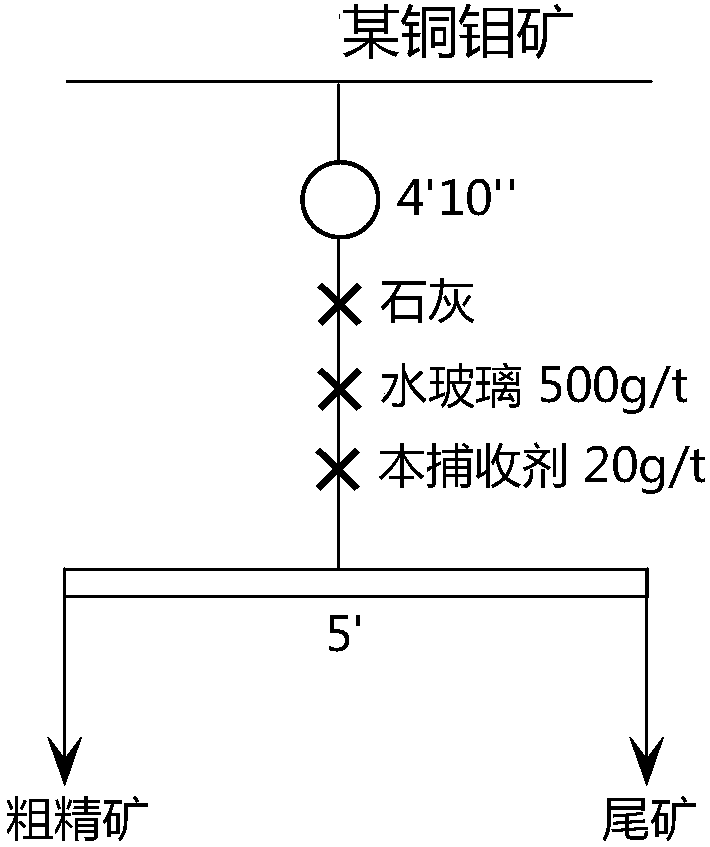

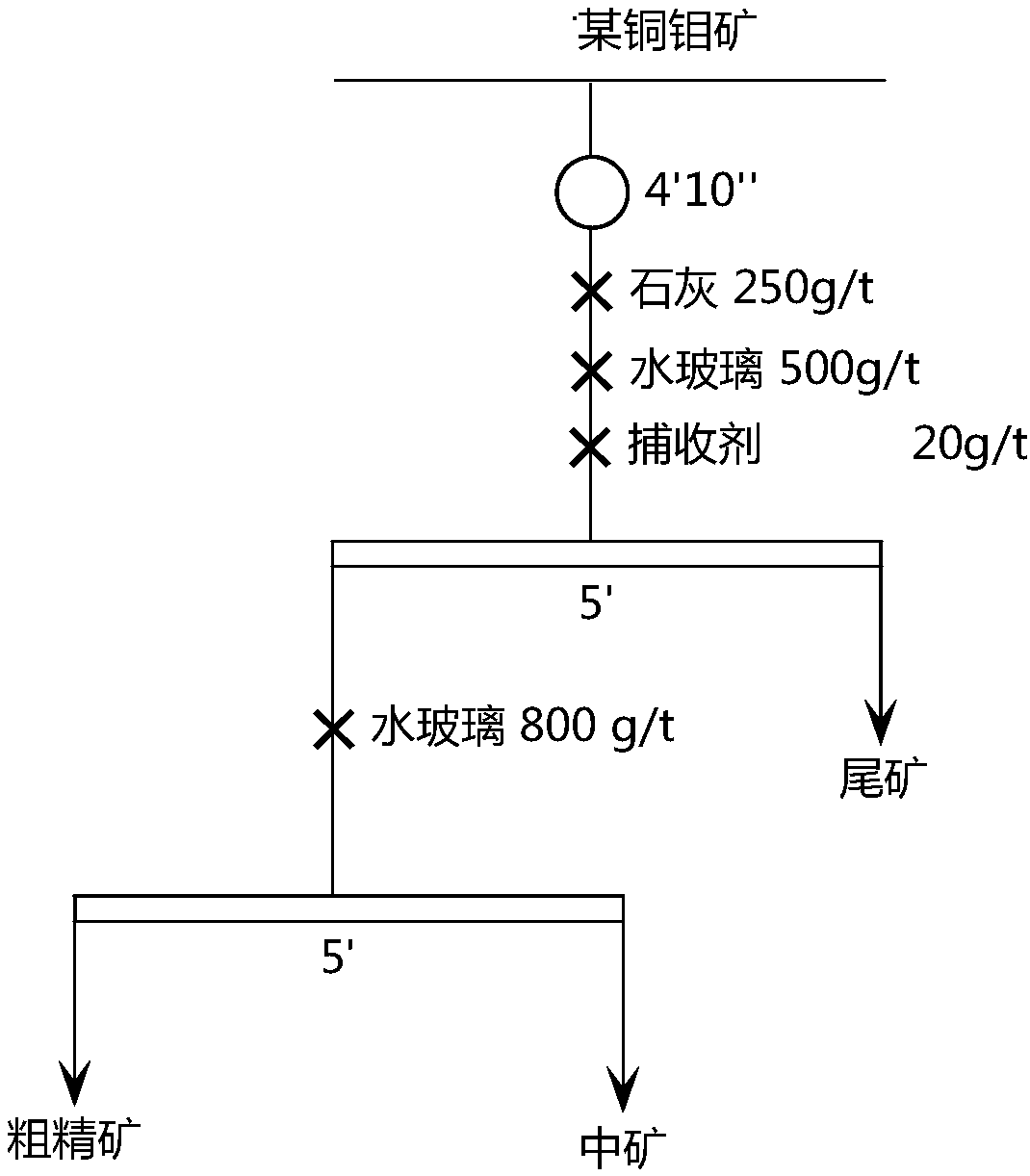

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] (1) The heavy oil is a heavy oil mixture obtained by mixing crude oil and / or residual heavy oil after oil extraction and processing, and is preferably a heavy oil mixture with uniform properties and no stratification.

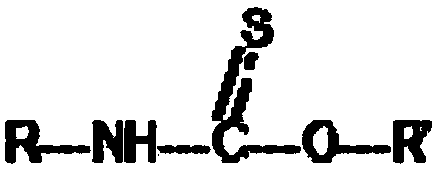

[0040] (2) The described thiocarbamate is an oily mixture with uniform and non-layered properties; for example: the described thiocarbamate can be a hydrocarbyl-thiocarbamate oily substance, and its general formula is as follows :

[0041]

[0042] Among them, R is C1-C6 straight chain or branched chain alkyl, C1-C6 straight chain or branched chain haloalkane, C1-C6 straight chain or branched chain amine, C1-C6 straight chain or branched chain alcohol, C1-C6 straight chain Or branched chain ester, phenyl, substituted phenyl; R' is C1-C8 straight chain or branched chain alkyl, C1-C8 straight chain or branched chain haloalkane, C1-C8 straight chain or branched chain amine, One of C1-C8 straight chain or branched chain alcohol, C1-C8 straight chain or b...

Embodiment 1

[0056] A low-alkalinity and high-selectivity copper-molybdenum flotation collector, prepared at room temperature, can be used for flotation in pulp with a pH value of 7-9, and its active ingredients include heavy oil, thiocarbamate Ester, hydrocarbon oil mixture, and the ratio of parts by weight of each component can be as shown in table 1 below:

[0057] Table 1

[0058] components

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com