High-performance insoluble sulfur for rubber and method for producing high-performance insoluble sulfur

A production method and high-performance technology, applied in the preparation/purification of sulfur, etc., can solve the problems of insoluble sulfur thermal stability and poor dispersion performance, improve the dispersion performance and thermal stability, ensure the application effect, and ensure the polymerization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

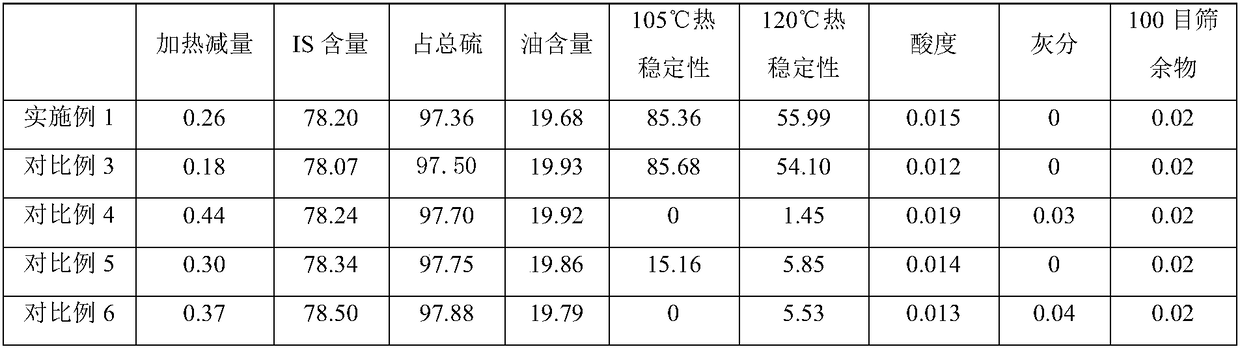

Examples

Embodiment 1

[0035] A kind of production method of high-performance insoluble sulfur for rubber of the present embodiment, comprises the following steps:

[0036] (1) Raw material gasification: using liquid sulfur as raw material, pump it into the gasification furnace for high-temperature gasification treatment;

[0037] (2) quenching treatment: passing the obtained sulfur gas into the quenching liquid for quenching treatment to obtain a viscoelastic polymer;

[0038] (3) tableting and washing: the obtained viscoelastic polymer is subjected to tableting treatment, and washed while pressing;

[0039] (4) Drying, crushing, and sieving: the pressed and washed viscoelastic polymer is placed in an oven for drying, and then the dried product is crushed and sieved to obtain a medium-content insoluble sulfur semi-finished product;

[0040] (5) Extraction: extract medium-content insoluble sulfur semi-finished products, dissolve soluble sulfur, and then separate;

[0041](6) Drying and sieving: th...

Embodiment 2

[0047] A kind of production method of high-performance insoluble sulfur for rubber of the present embodiment, comprises the following steps:

[0048] (1) Raw material gasification: use liquid sulfur as raw material, pump it into the gasification furnace for high-temperature gasification treatment; the temperature of the liquid sulfur raw material used in this embodiment is 146°C, and the gasification in the gasification furnace is controlled The temperature is 697°C, and the outlet gas temperature of the gasifier is 598°C.

[0049] (2) Quenching treatment: Pass the obtained sulfur gas into the quenching liquid for quenching treatment to obtain a viscoelastic polymer, and the quenching liquid is made of FeCl 3 、HNO 3 and water, and FeCl 3 The mass percentage of the total weight of the quenching liquid is 1.2%, HNO 3 The mass percentage of the total weight of the quenching liquid is 3.0%, and the temperature of the quenching liquid is 70°C.

[0050] The gasification and quen...

Embodiment 3

[0077] A kind of production method of high-performance insoluble sulfur for rubber of the present embodiment, comprises the following steps:

[0078] (1) Raw material gasification: use liquid sulfur as raw material, pump it into the gasification furnace for high-temperature gasification treatment; the temperature of the liquid sulfur raw material used in this embodiment is 150°C, and the gasification in the gasification furnace is controlled The temperature is 680°C, and the outlet gas temperature of the gasifier is 590°C.

[0079] (2) Quenching treatment: Pass the obtained sulfur gas into the quenching liquid for quenching treatment to obtain a viscoelastic polymer, and the quenching liquid is made of FeCl3 、HNO 3 formulated with water, and FeCl 3 The mass percentage of the total weight of the quenching liquid is 1.3%, HNO 3 The mass percentage of the total weight of the quenching liquid is 2.5%, and the temperature of the quenching liquid is 75°C.

[0080] (3) Tabletting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com