Septic tank pipeline filtering device

A filter device and septic tank technology, which is applied in the direction of filtration separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of reducing the working efficiency of septic tanks, long biodegradation time of sewage, and inability to achieve high-efficiency degradation, etc. problems, achieve the effect of shortening the degradation time, convenient construction and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

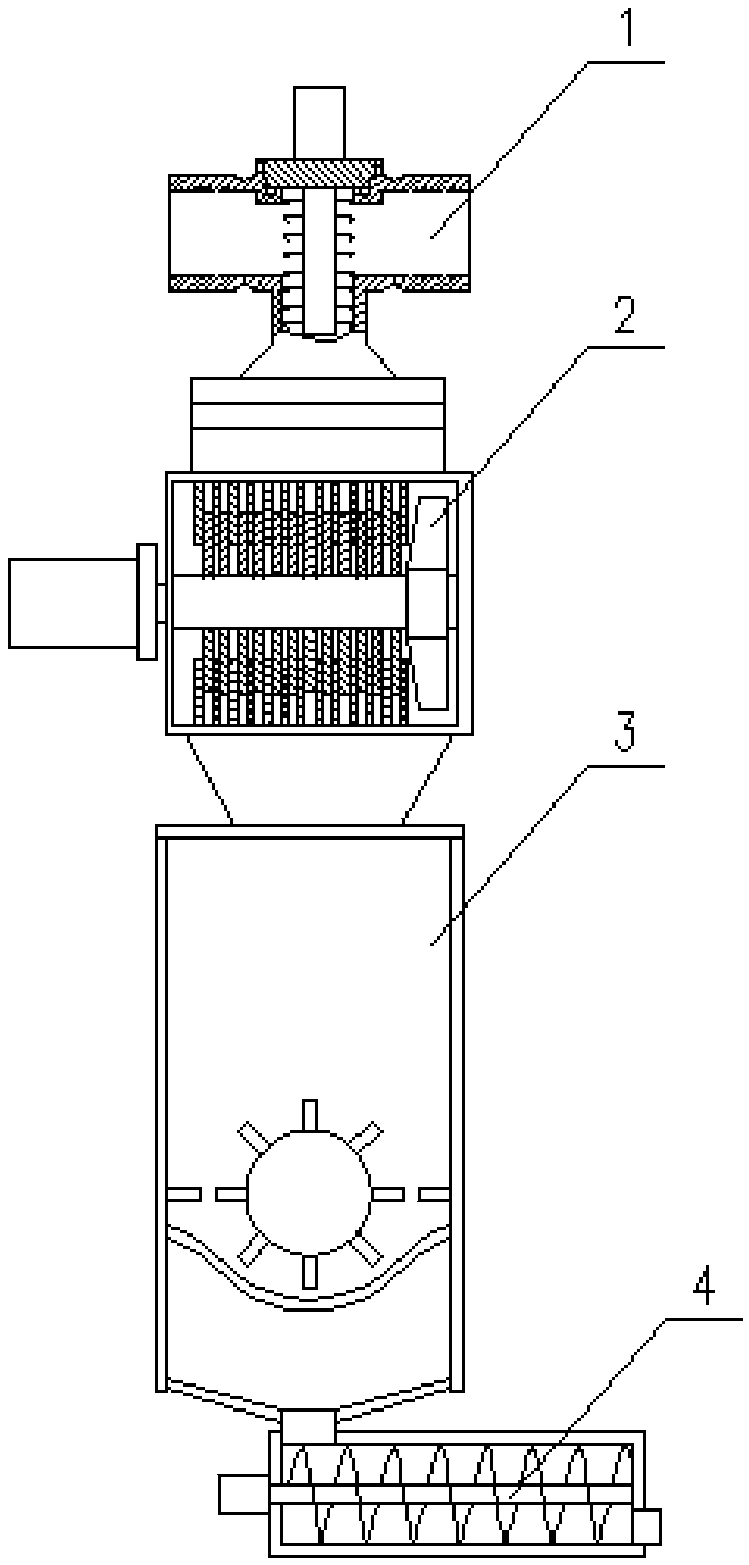

[0042] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, a septic tank pipeline filter device of this embodiment, including a screening device 1, a high-efficiency crushing device 2, a non-degradable solid particle filter device 3 and an agitation conveying device 4, the upper end of the high-efficiency crushing device 2 There is a water inlet 5, and the lower end of the high-efficiency pulverizing device 2 has a water outlet 6. The screening device 1 is connected and installed with the water inlet 5 of the high-efficiency pulverizing device 2, and the upper end of the non-degradable solid particle filter 3 is connected to the high-efficiency pulverizing The water outlet 6 of the device 2 is connected and installed, and the lower end of the non-degradable solid particle filter device 3 is equipped with a stirring conveying device 4;

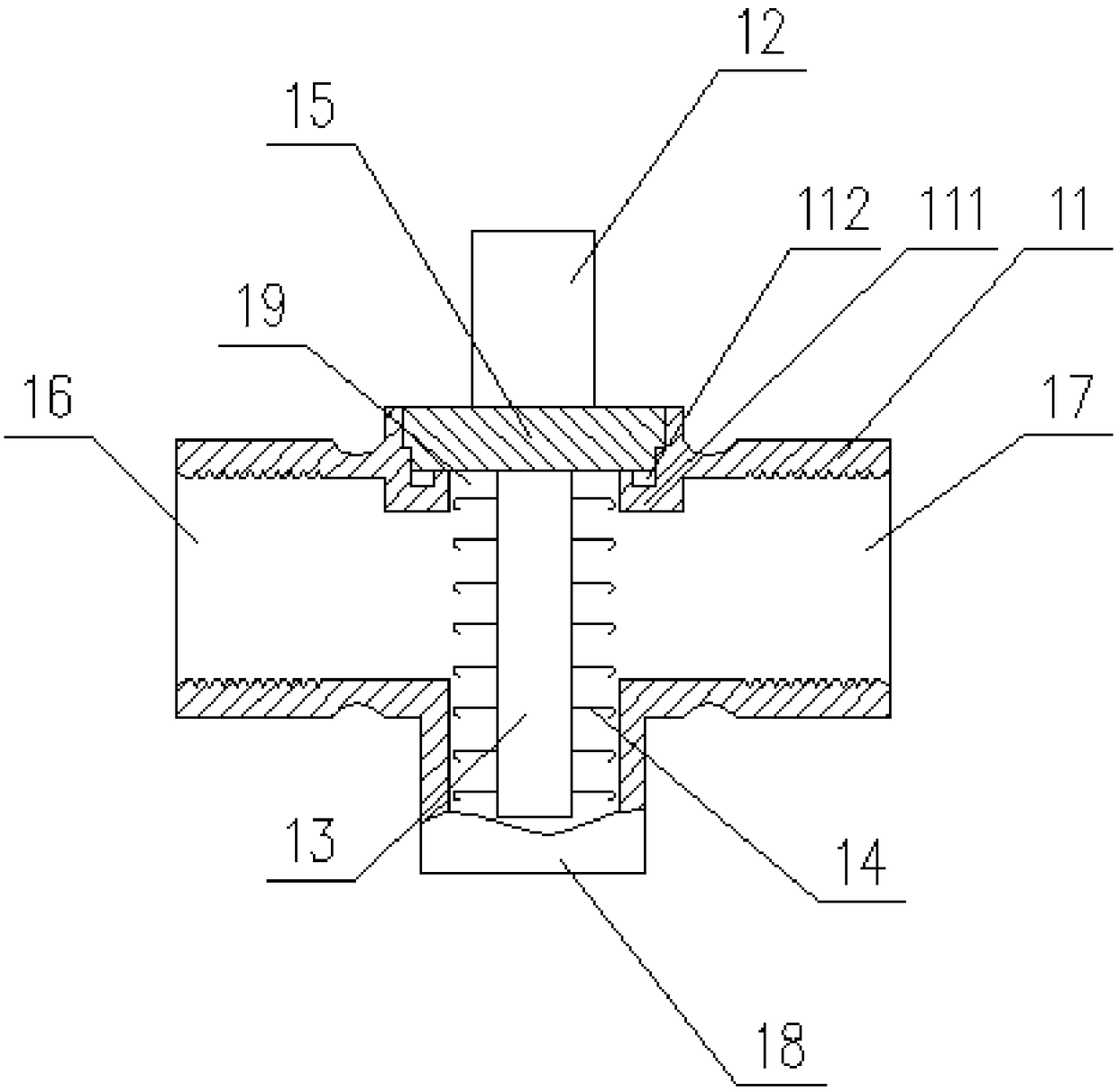

[0043] The screening device 1 includes a three-way connection body 11, a screening motor 12, a screening dr...

specific Embodiment approach 2

[0045] Specific implementation mode two: combination Figure 1-Figure 6 Describe this embodiment, a septic tank pipeline filter device of this embodiment, the installation platform 111 is processed with an annular groove 112, and the notch of the annular groove 112 has an annular gasket. Set up in this way, the working principle of the screening device 1 is that under the rotation of the screening motor 12, the screening drum 13 installed in the three-way connector 11 rotates. When 13 rotates, the bag-shaped plastic products mixed with domestic sewage entering the three-way connector 11 are hung upside down on the screening hook 14, thus realizing the screening of bag-shaped plastic products; 15 is detachably installed on the three-way connecting body 11, so the cleaning work of the belt-shaped plastic products hanging upside down on the screening hook 14 can be realized by regularly disassembling the screening drum mounting seat 15; the mounting table 111 proposed in this emb...

specific Embodiment approach 3

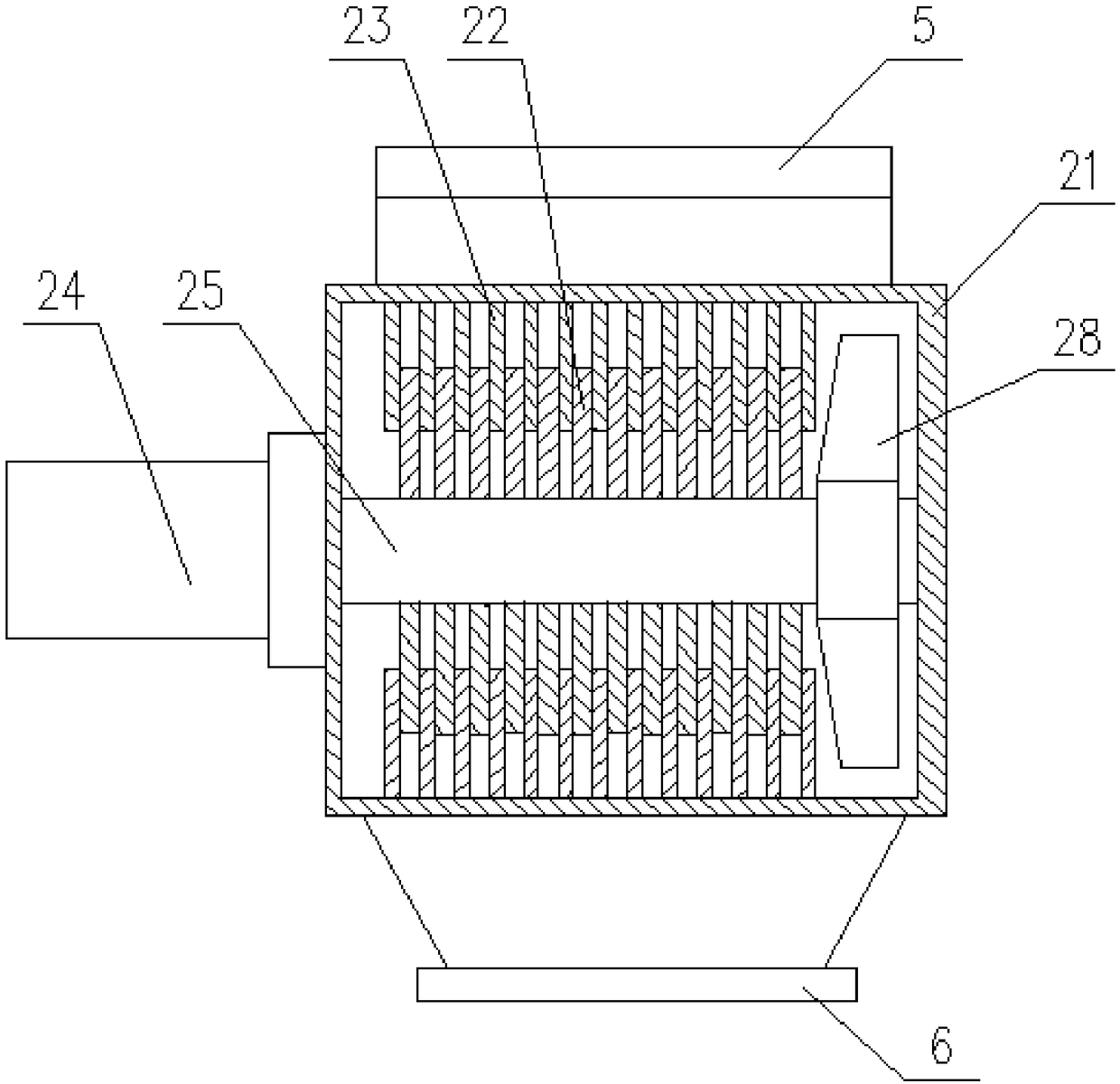

[0046] Specific implementation mode three: combination Figure 1-Figure 6 Describe this embodiment, a kind of septic tank pipe filter device of this embodiment, described high-efficiency pulverizing device 2 comprises pulverizing box body 21, first pulverizing hammer 22, second pulverizing hammer 23, pulverizing motor 24 and pulverizing Shaft 25, the crushing box 21 is a circular sealed cavity, the upper end of the crushing box 21 has a water inlet 5, the lower end of the crushing box 21 has a water outlet 6, and the inner wall of the crushing box 21 is evenly A plurality of second crushing hammers 23 are arranged, and the first crushing hammers 22 are installed in a circular array on the side wall of the crushing shaft 25, and the crushing shaft 25 is rotatably installed inside the crushing box 21, the described The pulverizing motor 24 is fixedly mounted on the outer sidewall of the pulverizing casing 21, and the output shaft of the pulverizing motor 24 stretches into the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com