Equipment for continuous vacuum distillation and separation of high arsenic alloy

A technology of distillation separation and vacuum, which is applied in the direction of improving process efficiency, etc., can solve the problem of large amount of arsenic-containing alloy materials, and achieve the effect of continuous cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

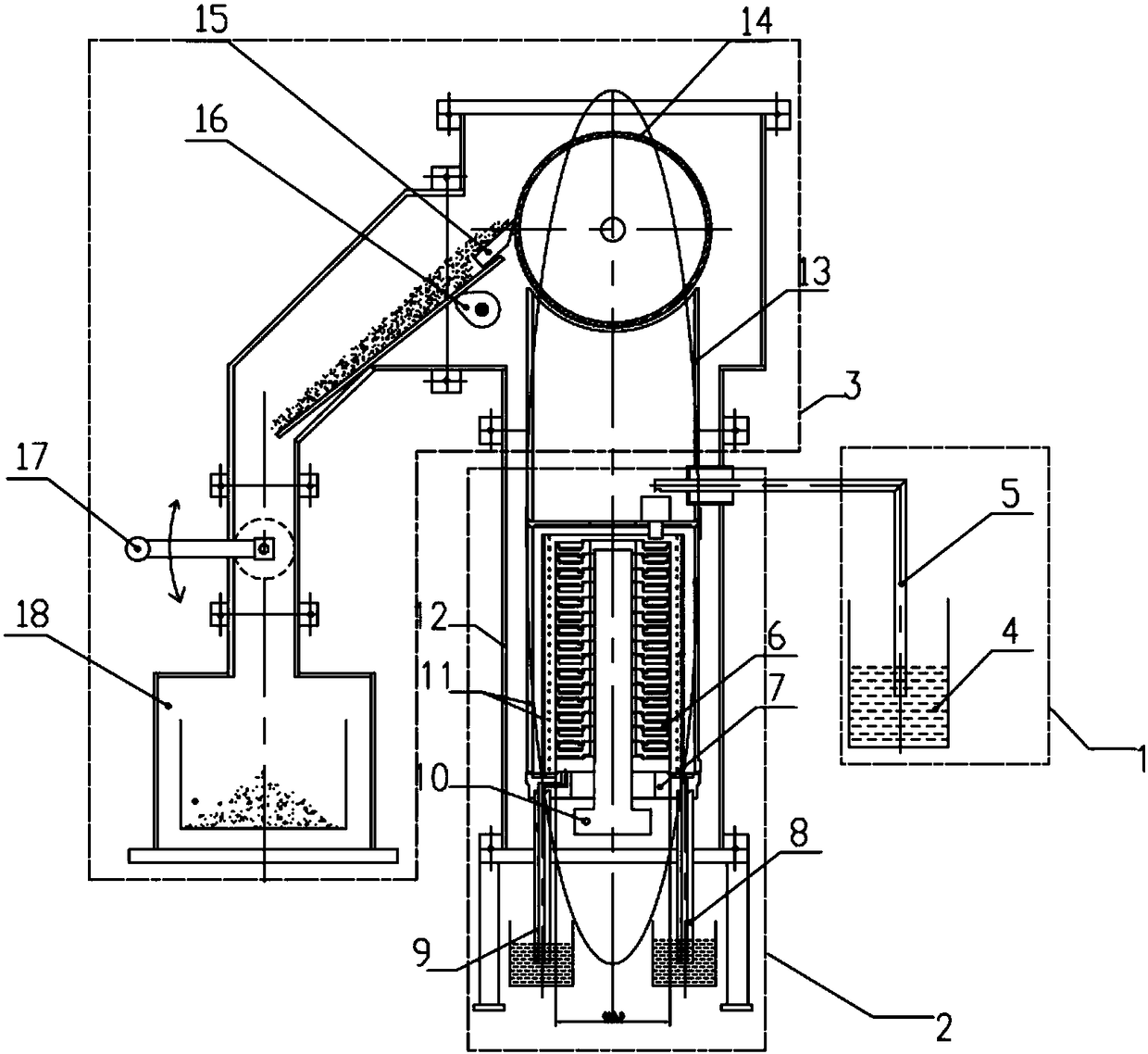

[0021]Put the high-arsenic tin-antimony alloy with 75% tin, 15% lead, 2% arsenic, and 7% antimony as the raw material in the melting feeding system, melt it into a liquid state by heating, seal the whole set of vacuum distillation furnace equipment, and start the vacuum system , when the pressure in the furnace is 35Pa, turn on the heating system, and when the predetermined temperature reaches 1350°C, keep warm and continue to distill. The melting feed system continuously and quantitatively feeds materials into the vacuum furnace during the distillation process. The added high-arsenic-tin-antimony alloy material begins to evaporate under the high-temperature vacuum atmosphere to form arsenic-antimony mixed metal vapor. The thick antimony alloy has a relatively high melting point, and most of the antimony vapor will condense on the condensation cover (11) into a liquid state and then flow to the collection pan (7), and then discharge the volatiles through the discharge port on ...

Embodiment 2

[0023] Put the high-arsenic tin alloy with 91% tin, 3.5% arsenic, 1.5% copper, and 0.07% antimony as the raw material in the melting feeding system, melt it into liquid by heating, seal the whole set of vacuum distillation furnace equipment, start the vacuum system, When the pressure in the furnace is 50Pa, the heating system is turned on, and when the predetermined temperature reaches 1450°C, the distillation is continued with heat preservation. The melting feed system continuously and quantitatively feeds materials into the vacuum furnace during the distillation process. The added high-arsenic-tin alloy material begins to evaporate under the high-temperature vacuum atmosphere to form arsenic-tin mixed metal vapor. The sublimation point of the crude arsenic alloy is low, and most of the crude arsenic alloy vapor after sublimation will evaporate to the condensing drum (14) with the lowest temperature on the upper end, and condense and adhere to the surface of the condensing dr...

Embodiment 3

[0026] Put the high-arsenic tin-lead-antimony alloy with 54.86% tin, 19.84% antimony, 16.35% lead, 4.5% arsenic, and 0.23% copper as the raw material in the melting feeding system, melt it into a liquid state by heating, and seal the whole set of vacuum distillation furnace equipment, start the vacuum system, and when the pressure in the furnace is 30Pa, turn on the heating system, and when the predetermined temperature reaches 1300°C, keep warm and continue to distill. The melting feed system continuously and quantitatively feeds materials into the vacuum furnace during the distillation process. The added high-arsenic, tin-lead-antimony alloy material begins to evaporate under the high-temperature vacuum atmosphere to form arsenic-lead-antimony mixed metal vapor. The melting point of lead and antimony is relatively high, and most of the lead and antimony vapor will condense on the condensation cover (11) into a liquid state and then flow to the collection pan (7), and then di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com