Single double-needle valve double-nozzle high-pressure common rail oil injector for medium-heavy diesel engine

A technology of high-pressure common rail and double nozzles, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., to achieve the effect of size reduction and improvement of vibration and noise levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

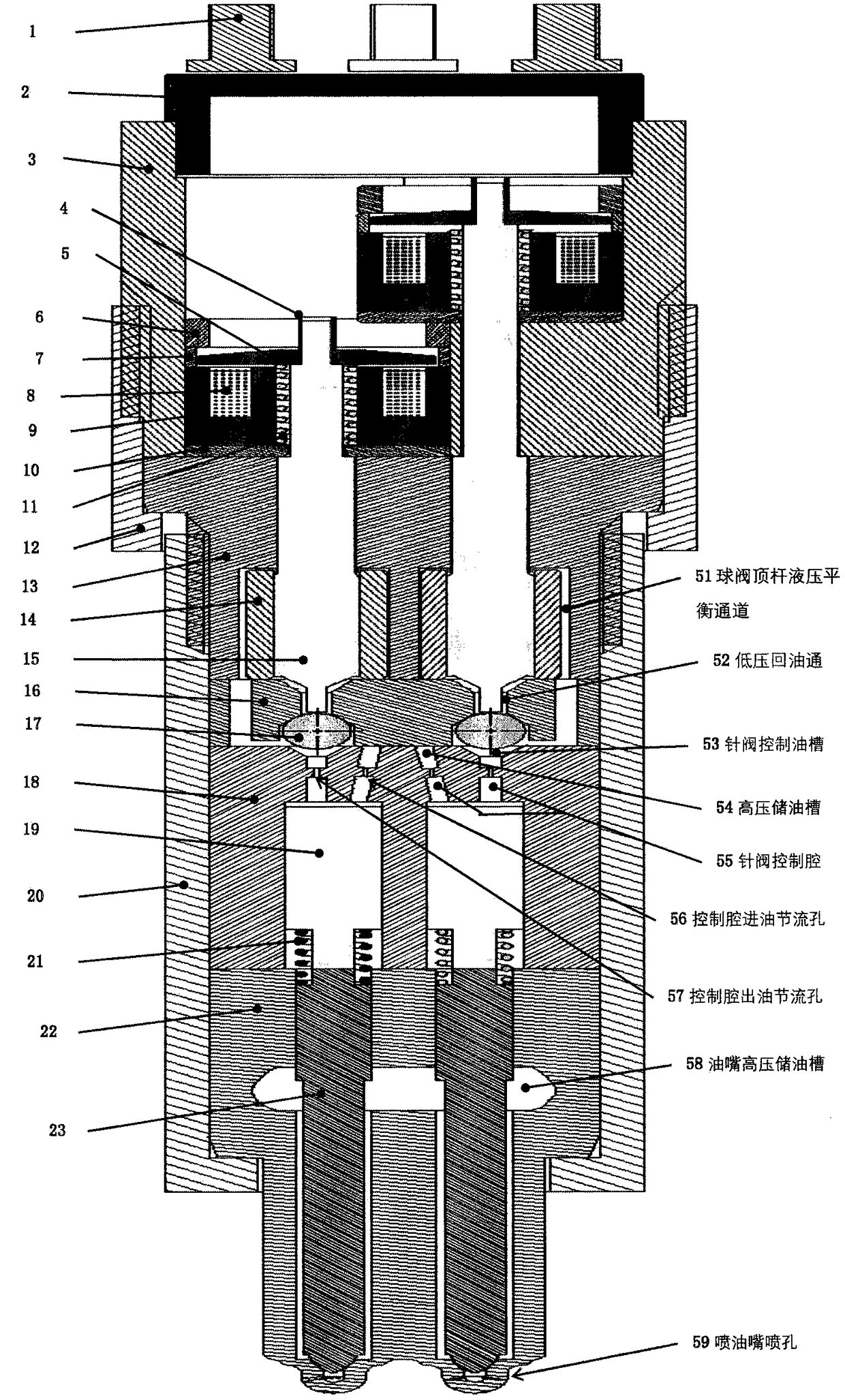

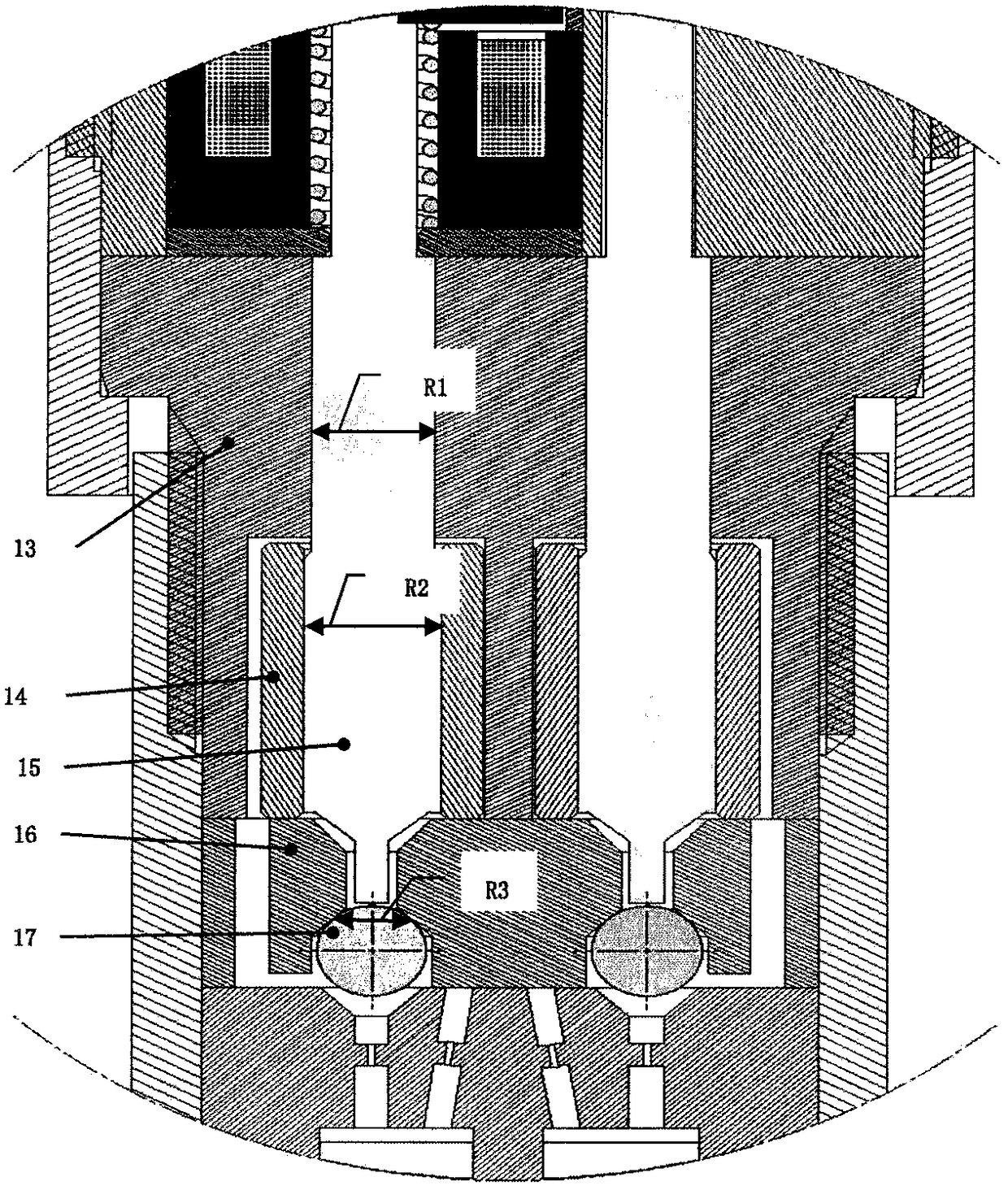

[0025] Such as figure 1 As shown, the high-pressure common rail fuel injector with single double needle valve and double nozzles of the present invention includes a magnetic core valve seat 3, a ball valve ram base mounting nut 12, a ball valve ram base 13, a ball valve base 16, and a valve needle control rod base 18. Install the nut 20 and the valve body 22 of the oil nozzle.

[0026] There are two solenoid valves inside the magnetic core valve seat, and each solenoid valve has an armature pressing ring 4, a solenoid valve armature 5, a magnetic core fixing pressing ring 6, a magnetic isolation ring 7, a solenoid valve coil 8, and a solenoid valve magnet. Core 9, air gap adjustment ring 10, armature preload spring 11 and ball valve ejector rod 15. Using the friction force generated by the interference fit between the armature pressing ring 4 and the end of the ball valve mandrel 15, the solenoid valve armature 5 is fixed on the ball valve mandrel 15; the magnetic core fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com