Polarized light microscopy-X-ray diffraction method for qualitative detection of asbestos in electronic products

An electronic product and polarizing microscopy technology, which is applied in the direction of material analysis using wave/particle radiation, measuring devices, and material analysis through optical means, can solve the complex structure of asbestos components, difficulty in achieving results, and low universality. and other issues to achieve the effect of avoiding trade risks, avoiding asbestos hazards, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

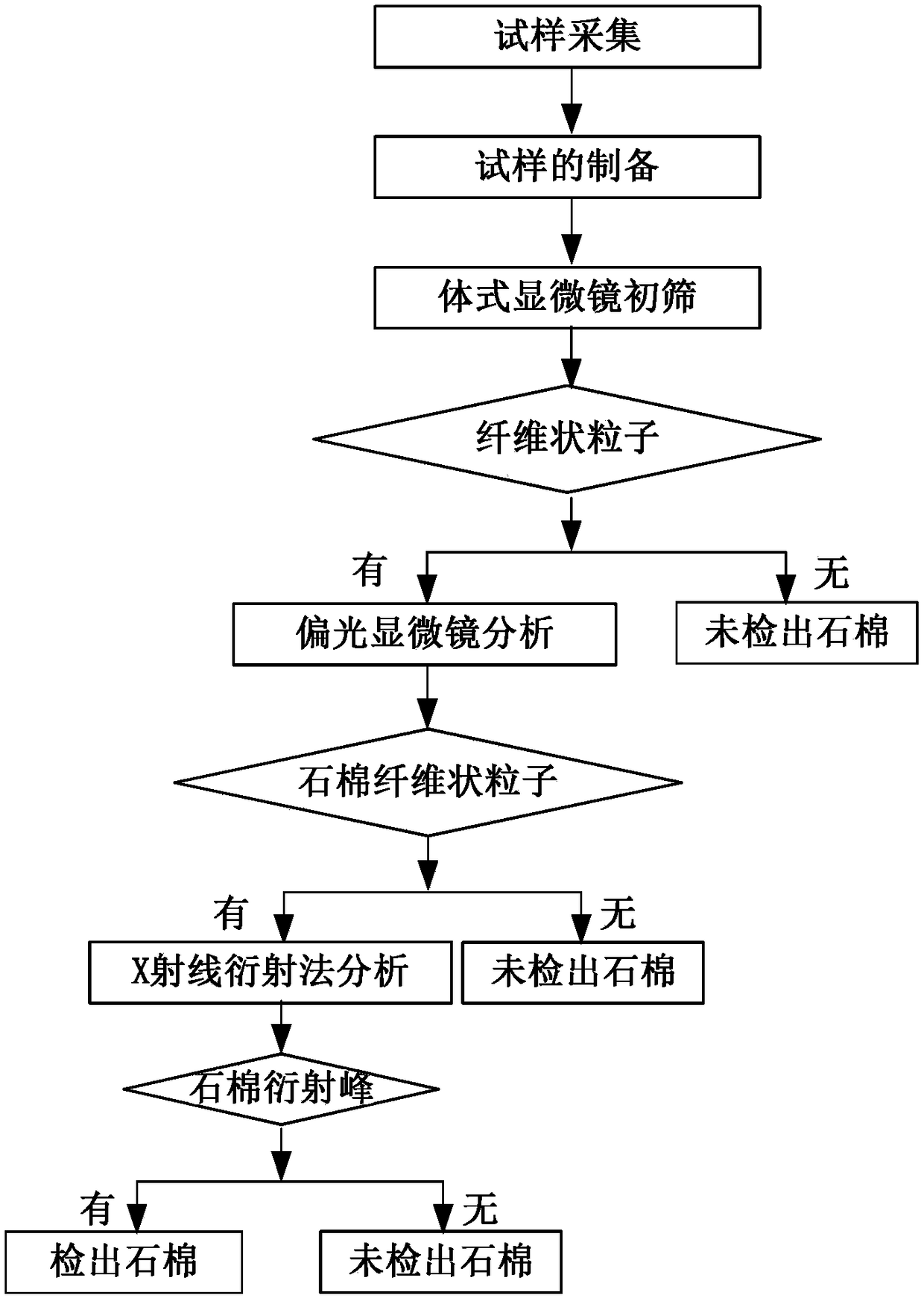

[0018] A kind of polarization micro-X-ray diffraction method for qualitative detection of asbestos in electronic products, the specific steps are as follows:

[0019] Step 1. Sampling and ashing treatment. After pulverizing about 5g of the sample on the electronic product to be tested, the sample is placed in a crucible and placed in a muffle furnace. The ashing temperature is greater than 500°C to remove organic substances. The ashing treatment is specific Ashing at 450°C±10°C for 1h.

[0020] Step 2, sample sieving. After the ashed electronic product sample is cooled to room temperature in a desiccator, it is ground in an agate mortar and sieved through a metal sieve with a pore size of 425 μm to 500 μm.

[0021] Step 3: Take a sample to make a specimen, weigh 20 mg of the sieved electronic product sample, place it in a 100 mL Erlenmeyer fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com