A kind of method and its application of biological fermentation preparation lavender absolute oil

A technology of lavender absolute oil and bio-fermentation, which is applied in the preparation of tobacco, application, tobacco, etc., can solve the problems of aftertaste with bitterness, strong irritation, single aroma, etc., and achieve the goal of improving taste, reducing irritation, and increasing extraction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

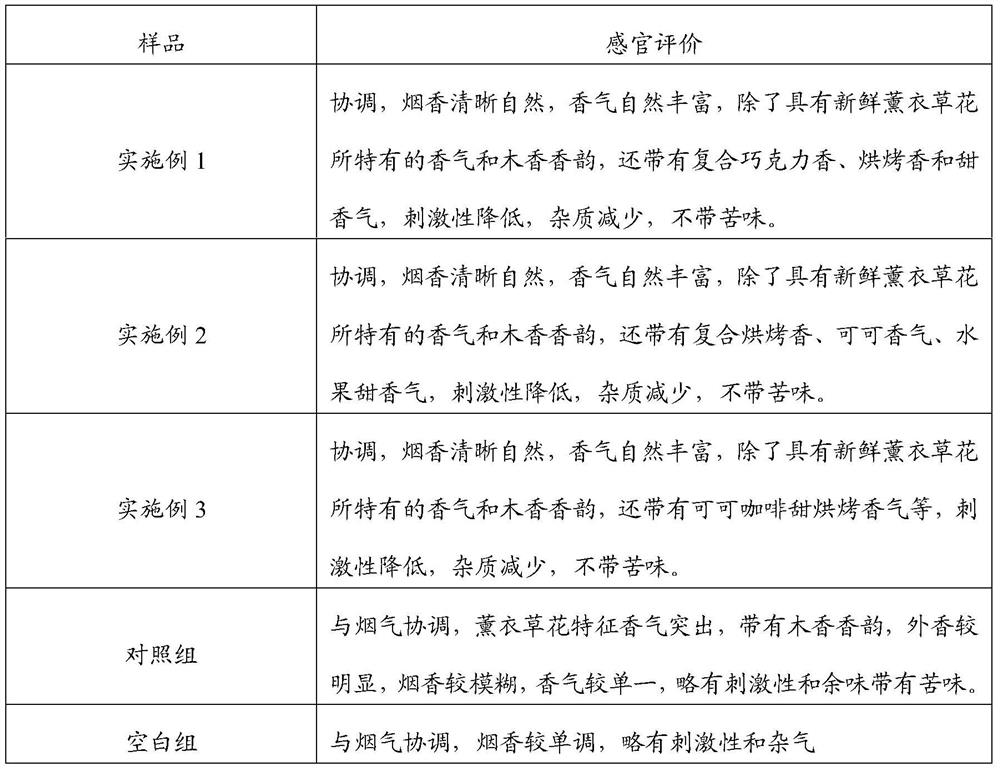

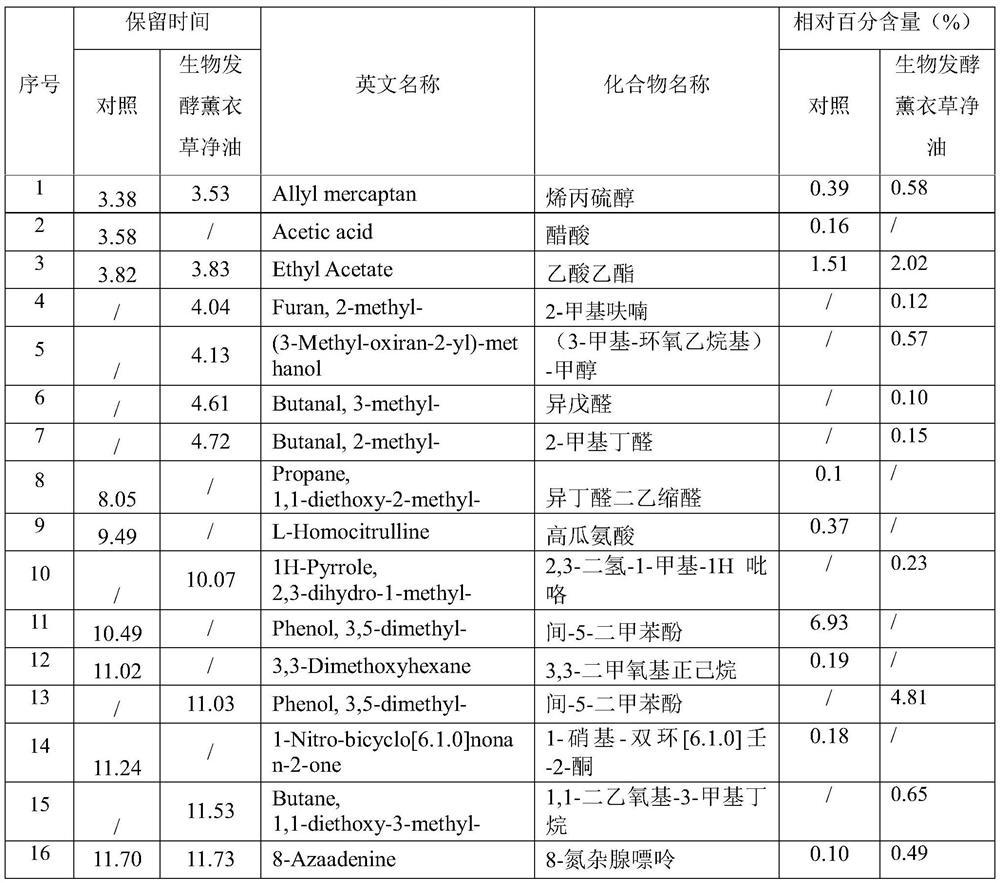

Examples

Embodiment 1

[0026] A preparation method for preparing lavender absolute by biological fermentation, comprising the steps of:

[0027] (1) Low-temperature ultrasonic pretreatment: mix the dried flower spikes of lavender and water evenly at a mass ratio of 1:10, pour them into a microwave extractor for pretreatment, and obtain the mixed material for microwave extraction of flower spikes of lavender;

[0028] Further, the working conditions of the microwave extractor described in step (1) are a temperature of 2°C, a microwave frequency of 2450MHz, a microwave power of 300W, and a time of 12 minutes;

[0029] (2) Incubation and fermentation: the lavender fringe microwave extraction mixture material obtained in step (1) is poured into the fermentation extraction tank together, add malic acid, oxalic acid, citrate, then add compound biological agent and stir evenly, be heated to 36 ℃, incubate and ferment for 3.5 days;

[0030] Described malic acid, oxalic acid, citric acid are food grade, acc...

Embodiment 2

[0039] A preparation method for preparing lavender absolute by biological fermentation, comprising the steps of:

[0040] (1) Low-temperature ultrasonic pretreatment: mix the dried flower spikes of lavender and water evenly at a mass ratio of 1:15, pour them into a microwave extractor for pretreatment, and obtain the mixed material for microwave extraction of flower spikes of lavender;

[0041] Further, the working conditions of the microwave extractor in step (1) are temperature 5°C, microwave frequency: 2450MHz, microwave power 500W, and time 9min;

[0042](2) Incubation and fermentation: the lavender fringe microwave extraction mixture material that step (1) obtains is poured in the fermentation extraction tank together, adds oxalic acid, citrate, maleic acid, then adds compound biological agent and stirs, is heated to 45°C, incubate and ferment for 2.5 days;

[0043] Described oxalic acid, citric acid, maleic acid are food grade, account for 0.24% of the raw material qual...

Embodiment 3

[0052] A preparation method for preparing lavender absolute by biological fermentation, comprising the steps of:

[0053] (1) Low-temperature ultrasonic pretreatment: mix the dried flower spikes of lavender and water evenly at a mass ratio of 1:20, pour them into a microwave extractor for pretreatment, and obtain the mixed material for microwave extraction of flower spikes of lavender;

[0054] Further, the working conditions of the microwave extractor in step (1) are temperature 6°C, microwave frequency: 2450MHz, microwave power 900W, and time 3min;

[0055] (2) Incubation and fermentation: the lavender fringe microwave extraction mixture material that step (1) obtains is poured into the fermentation extraction tank together, add malic acid, oxalic acid, citrate, maleic acid, then add compound biological agent and stir evenly , heated to 52°C, incubated and fermented for 2.5 days;

[0056] Described malic acid, oxalic acid, citric acid, maleic acid are food grade, account fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com