Nb-Rh co-doped titanium dioxide photocatalyst, and preparation method and application thereof

A technology for catalysts and uses, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low catalytic efficiency of catalysts, and achieve easy large-scale production, The effect of high photocatalytic hydrogen production activity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

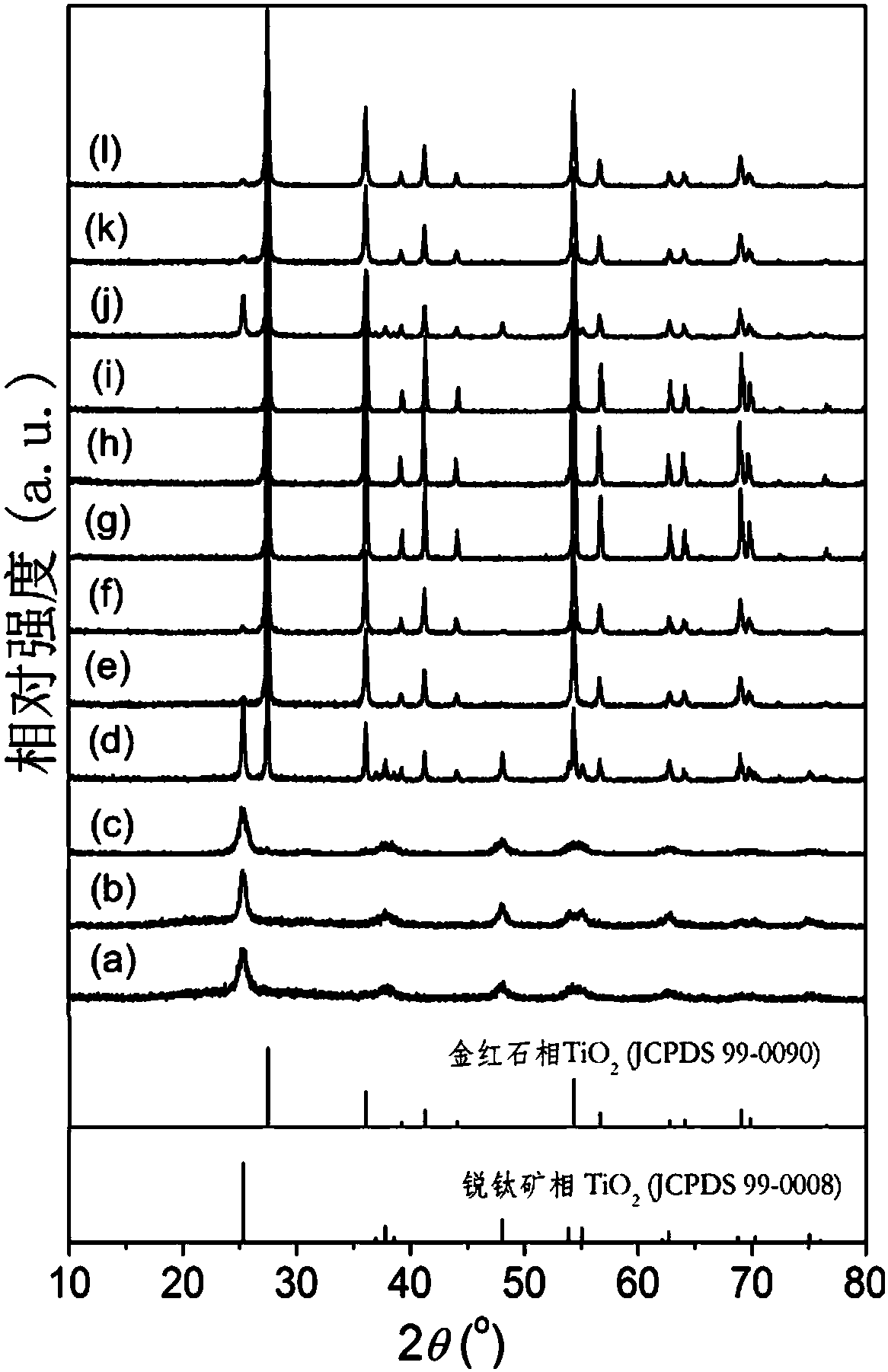

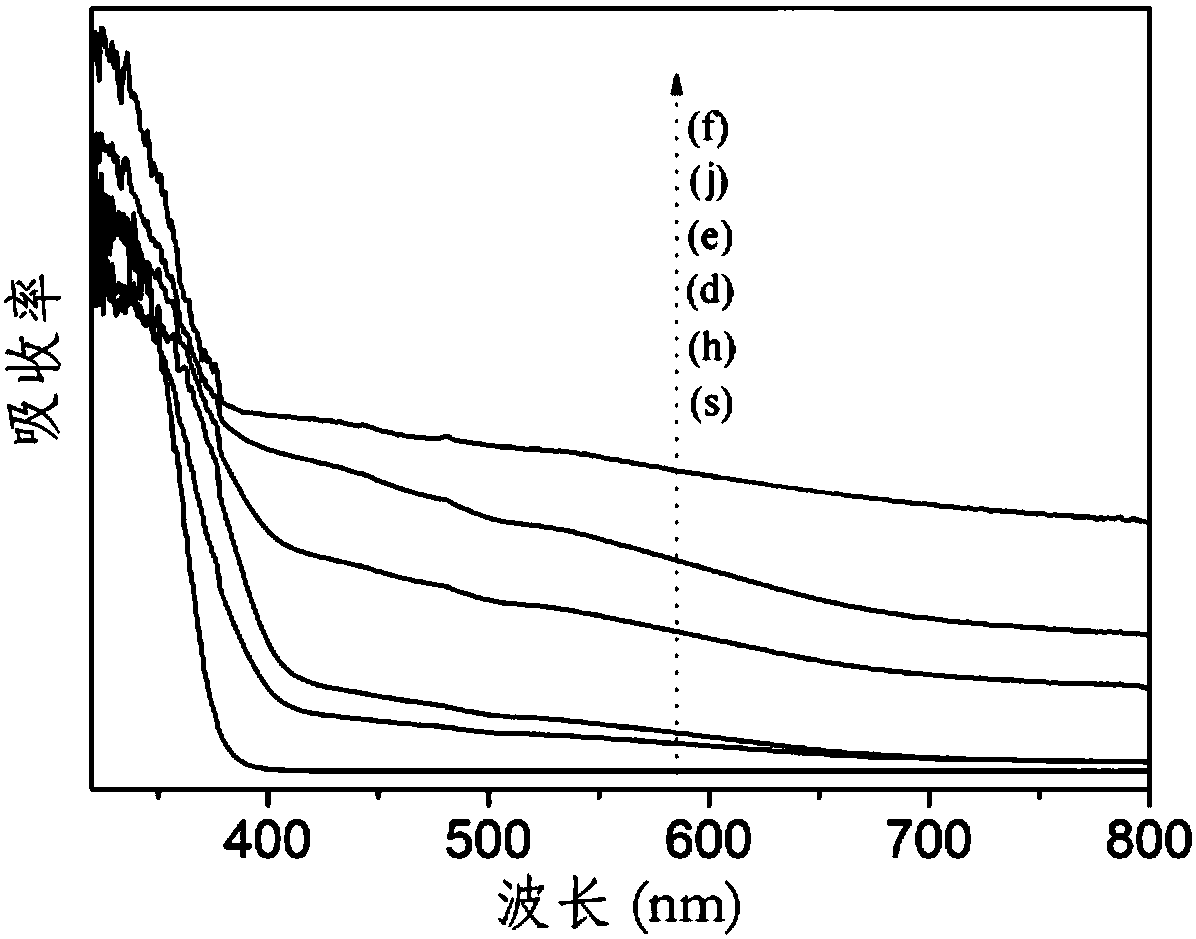

Embodiment 1

[0049] 0.3mL of hydrochloric acid with a mass fraction of 35%, 0.2mL of 0.05M ethanol solution of niobium pentachloride, 1mL of 0.01M ethanol solution of rhodium chloride and 3.4g of butyl titanate were sequentially added to 10mL of absolute ethanol solution and stirred to form A clear solution was then slowly added dropwise with distilled water while continuing to stir until a gel formed. The gel was dried in an oven at 70°C for 20h, and then calcined in a muffle furnace at 450°C for 2h to obtain Ti 0.998 Nb 0.001 Rh 0.001 o 2 Nano powder.

Embodiment 2

[0051] 0.3mL of hydrochloric acid with a mass fraction of 35%, 10.5mL of 0.05M ethanol solution of niobium pentachloride, 1.1mL of 0.01M ethanol solution of rhodium chloride and 3.4g of butyl titanate were successively added to 10mL of absolute ethanol solution, stirred to A clear solution formed, and distilled water was slowly added dropwise while continuing to stir until a gel formed. The gel was dried in an oven at 70°C for 20h, and then calcined in a muffle furnace at 450°C for 2h to obtain Ti 0.949 Nb 0.05 Rh 0.001 o 2 Nano powder.

Embodiment 3

[0053] 0.3mL of hydrochloric acid with a mass fraction of 35%, 0.2mL of 0.05M ethanol solution of niobium pentachloride, 53mL of 0.01M ethanol solution of rhodium chloride and 3.4g of butyl titanate were sequentially added to 10mL of absolute ethanol solution and stirred to form A clear solution was then slowly added dropwise with distilled water while continuing to stir until a gel formed. The gel was dried in an oven at 70°C for 20h, and then calcined in a muffle furnace at 450°C for 2h to obtain Ti 0.949 Nb 0.001 Rh 0.05 o 2 Nano powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com