Composite panels for furniture

A composite board and furniture technology, applied in the field of furniture, can solve the problems of easy deformation of the particleboard, single function of the board, and lack of moisture-proof performance of the blockboard, so as to achieve good anti-mildew effect, improve tear resistance, and increase bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

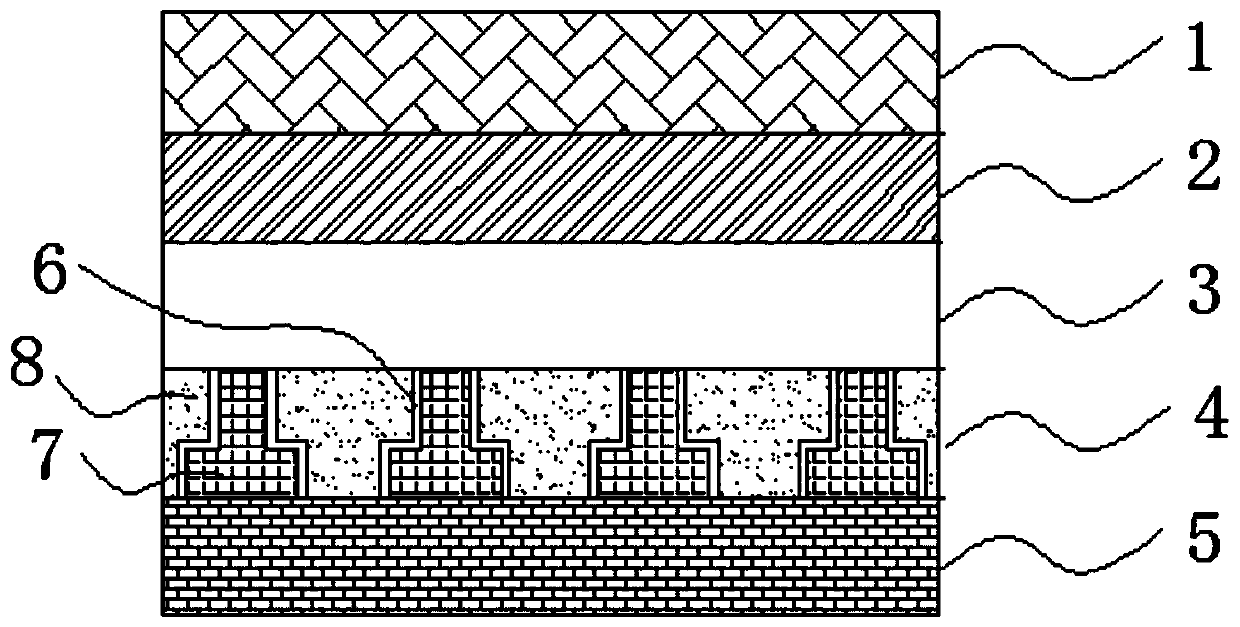

[0028] Embodiment: a kind of composite board for furniture, such as figure 1 As shown, it includes a substrate layer 1, a moisture-proof layer 2, a mildew-proof layer 3, an anti-deformation layer 4 and a stain-resistant layer 5, and the moisture-proof layer 2 is located between the substrate layer 1 and the mildew-proof layer 3, The anti-mildew layer 3 is located between the moisture-proof layer 2 and the anti-deformation layer 4, and the anti-deformation layer 4 is located between the anti-mildew layer 3 and the stain-resistant layer 5;

[0029] The substrate layer 1 is a PPC substrate layer or a PVC substrate layer, and the thickness of the substrate layer is 8-10mm;

[0030] The moisture-proof layer 2 is a plurality of geotextile layers and silica gel filled between adjacent geotextile layers, and the thickness of the moisture-proof layer is 3-4mm;

[0031] The anti-mildew layer 3 is a powder layer comprising nano-silver and nano-copper, and the thickness of the anti-milde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com