Method for improving dispersing performance of graphene

A technology of dispersion performance and graphene, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of graphene performance impact, dispersion efficiency, dispersion stability, graphene structure damage, graphene easy to agglomerate, etc. Achieve the effects of high dispersion stability, easy industrialization and high dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

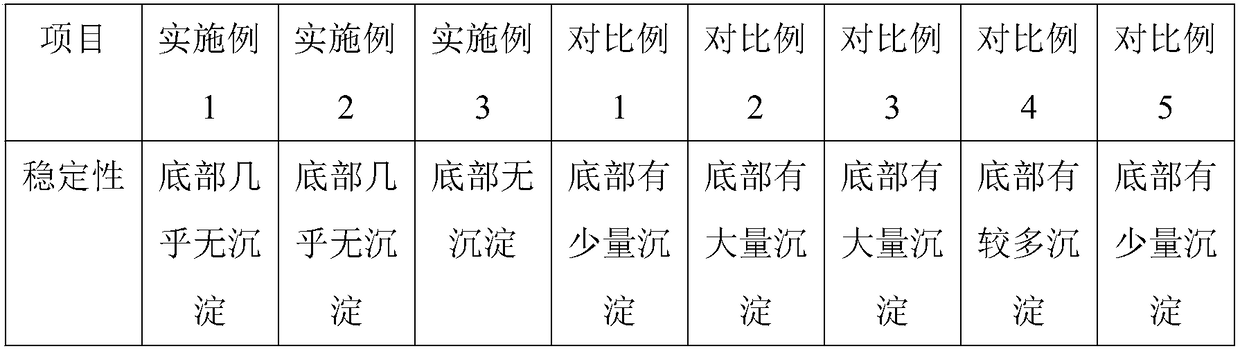

Examples

Embodiment 1

[0027] Embodiment 1, a kind of method that improves graphene dispersion property

[0028] The method for described improving graphene dispersibility, comprises the following steps:

[0029] S1 Add graphene to the container, add N,N-dimethylformamide, the amount of N,N-dimethylformamide added is 28 times the mass of graphene, mix well, seal the container, and use ultrasonic cell The pulverizer is ultrasonic, the ultrasonic frequency is 23kHz, the ultrasonic time and the intermittent time are 3s and 2s respectively, in order to make the temperature of the dispersion liquid lower than 30°C, the container is treated in an ice bath to obtain a graphene / DMF mixture, which is filtered to obtain a surface Functionalized graphene;

[0030] S2 disperses the surface-functionalized graphene obtained in step S1 in deionized water through an ultrasonic water bath, the ultrasonic power is 300W, and the ultrasonic time is 15min, so that the content of the surface-functionalized graphene in t...

Embodiment 2

[0033] Embodiment 2, a kind of method that improves graphene dispersion property

[0034] The method for described improving graphene dispersibility, comprises the following steps:

[0035] S1 Add graphene to the container, add N,N-dimethylformamide, the amount of N,N-dimethylformamide added is 32 times the mass of graphene, mix well, seal the container, and use ultrasonic cell The pulverizer is ultrasonic, the ultrasonic frequency is 25kHz, the ultrasonic time and the intermittent time are 3s and 2s respectively, in order to make the temperature of the dispersion liquid lower than 30°C, the container is treated in an ice bath to obtain a graphene / DMF mixture, which is filtered to obtain a surface Functionalized graphene;

[0036] S2 disperses the surface-functionalized graphene obtained in step S1 in deionized water through an ultrasonic water bath, the ultrasonic power is 500W, and the ultrasonic time is 25min, so that the content of surface-functionalized graphene in the s...

Embodiment 3

[0039] Embodiment 3, a kind of method that improves graphene dispersion property

[0040] The method for described improving graphene dispersibility, comprises the following steps:

[0041] S1 Add graphene to the container, add N,N-dimethylformamide, the amount of N,N-dimethylformamide added is 30 times the mass of graphene, mix well, seal the container, and use ultrasonic cell The pulverizer is ultrasonic, the ultrasonic frequency is 24kHz, the ultrasonic time and the intermittent time are 3s and 2s respectively, in order to make the temperature of the dispersion liquid lower than 30°C, the container is treated in an ice bath to obtain a graphene / DMF mixture, which is filtered to obtain a surface Functionalized graphene;

[0042] S2 disperses the surface-functionalized graphene obtained in step S1 in deionized water through an ultrasonic water bath. agent and vitamin C, the above surfactant is composed of dimethyl diallyl ammonium chloride-styrene-acrylamide copolymer and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com