Preparation method and application of peroxidase-like copper hydroxide nanorods

A technology of peroxidase and copper hydroxide, which is applied in the field of simulated enzymes and analytical chemistry, can solve the problems of unsatisfactory catalytic activity, high price, time-consuming and labor-consuming, etc., and achieve excellent catalytic activity, low cost, and simple preparation process fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing a peroxidase-like copper hydroxide nanorod of the present invention, comprising the steps of:

[0046] 1) Dissolve anhydrous cupric chloride and cuprous chloride with a molar ratio of 1:0.5 in 50 mL of deionized water, stir in a water bath at a water temperature of 30°C for 10 min and mix evenly to obtain a light green mixed solution;

[0047] 2) Add ammonia water with a mass concentration of 36% drop by drop into the mixed solution obtained in the first step using a disposable dropper, test the pH while adding dropwise, adjust the pH to 9.5, and continue stirring for 30 minutes, the color of the original solution turns dark blue;

[0048] 3) Centrifuge at 9000r / min for 5 minutes to separate the product, wash the product with deionized water, and dry it in vacuum at 35°C to obtain a sky blue solid.

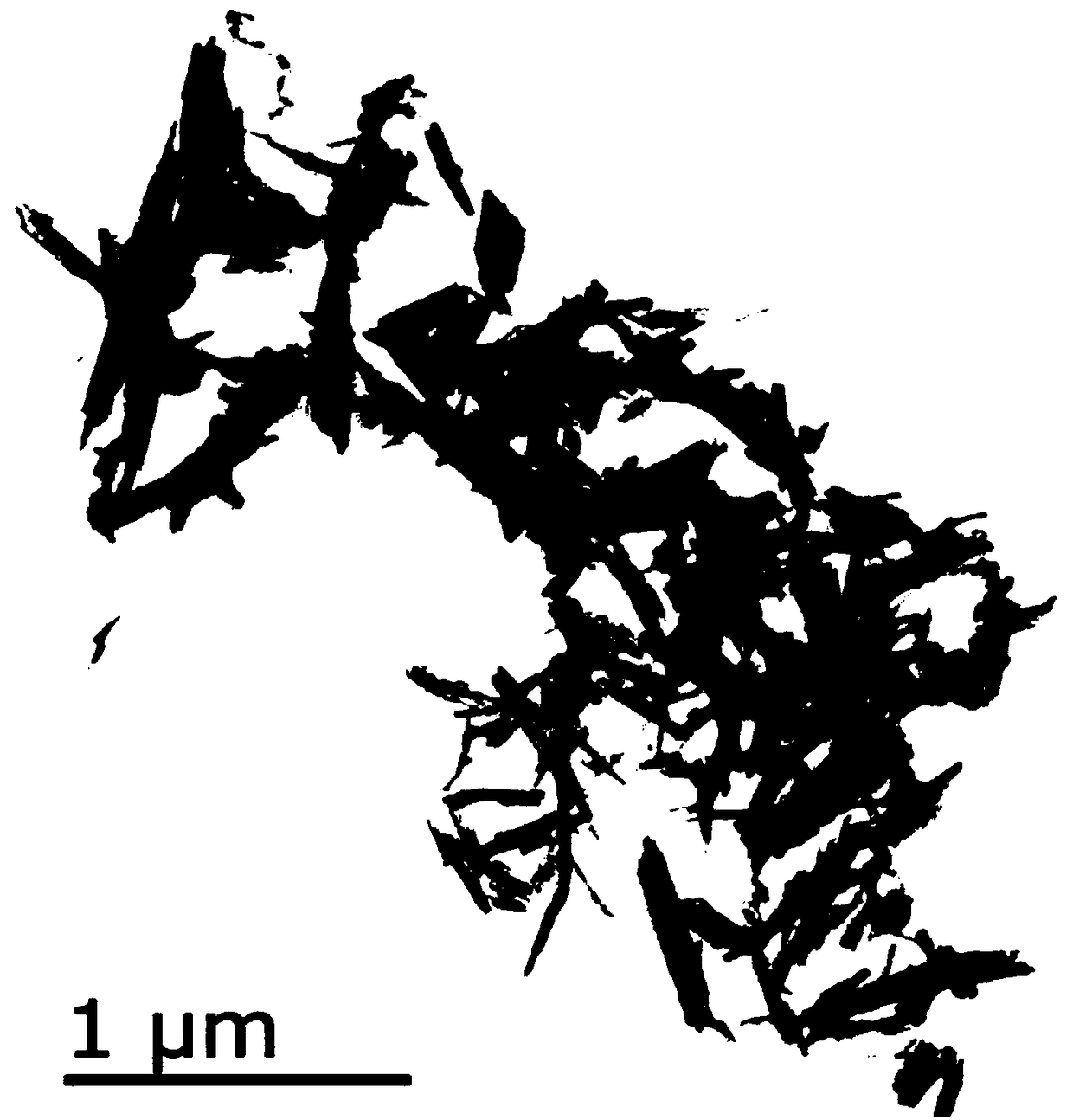

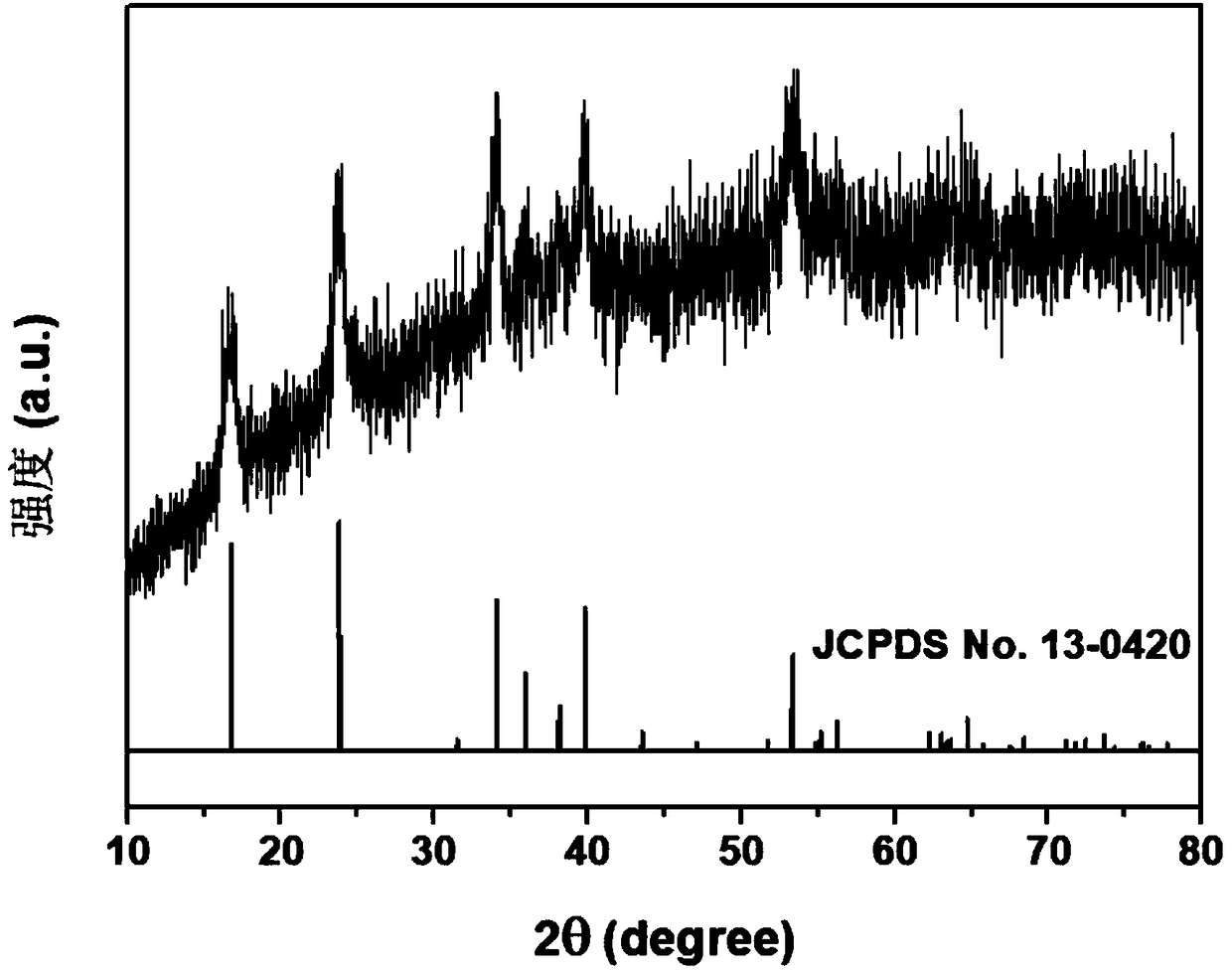

[0049] The obtained product was in the form of nanorods ( figure 1 and figure 2 ) has a length of 150nm to 2μm and a diameter of 30 to 50nm, and ...

Embodiment 2

[0055] A method for preparing a peroxidase-like copper hydroxide nanorod of the present invention, comprising the steps of:

[0056] 1) Dissolve anhydrous cupric chloride and cuprous chloride with a molar ratio of 1:1 in 60mL of deionized water, stir in a water bath at a water temperature of 40°C for 15min and mix evenly to obtain a light green mixed solution;

[0057] 2) Add ammonia water with a mass concentration of 37% to the mixed solution obtained in the first step drop by drop using a disposable dropper, test the pH while adding, adjust the pH to 10.5, and continue stirring for 40 minutes, the color of the original solution turns dark blue;

[0058] 3) Centrifuge at a speed of 10000r / min for 5 minutes to separate the product, wash the product with deionized water, and dry it in vacuum at 40°C to obtain a sky blue solid nanorod with a length of 150nm-2μm and a diameter of 30-50nm.

[0059] The application experiment of copper hydroxide peroxidase catalyzing hydrogen perox...

Embodiment 3

[0064] A method for preparing a peroxidase-like copper hydroxide nanorod of the present invention, comprising the steps of:

[0065] 1) Dissolve anhydrous cupric chloride and cuprous chloride with a molar ratio of 1:1 in 60 mL of deionized water, stir in a water bath at a water temperature of 40°C for 15 minutes and mix evenly to obtain a light green mixed solution;

[0066] 2) Add ammonia water with a mass concentration of 37% to the mixed solution obtained in the first step drop by drop using a disposable dropper, test the pH while adding, adjust the pH to 11, and continue stirring for 60 minutes, the color of the original solution turns dark blue;

[0067] 3) Centrifuge at a speed of 10000r / min for 5 minutes to separate the product, wash the product with deionized water, and dry it in vacuum at 40°C to obtain a sky blue solid nanorod with a length of 150nm-2μm and a diameter of 30-50nm.

[0068] The application experiment of copper hydroxide peroxidase catalyzing hydrogen p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com