Calcium magnesium polyphosphate fertilizer prepared from phosphoric acid and phosphorus tailings as raw materials and preparation method thereof

A technology of calcium polyphosphate and phosphate tailings, which is applied in calcium fertilizers, phosphate fertilizers, magnesium fertilizers, etc., can solve the problems of environmental pollution of phosphate tailings and low availability of magnesium, so as to improve the comprehensive utilization rate of resources and ensure reliable product quality. , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing calcium magnesium polyphosphate fertilizer using wet-process phosphoric acid and phosphorus tailings as raw materials, the used raw material indicators are as follows:

[0035] Wet-process phosphoric acid: w(P 2 o 5 ) 23.39%, w (MgO) 1.01%, w (CaO) 0.12%;

[0036] Phosphorus tailings: w(P 2 o 5 ) 7.07%, w (MgO) 16.2%, w (CaO) 35.11%;

[0037] Including the following steps:

[0038] (1) 100kg of phosphorus tailings and 400kg of wet-process phosphoric acid were mixed and reacted for 1.5h at normal temperature in a reactor to obtain a reaction mixture;

[0039] (3) Calcining the reaction mixture obtained above at 350° C. for 3.5 hours, and grinding to obtain the calcium magnesium polyphosphate product.

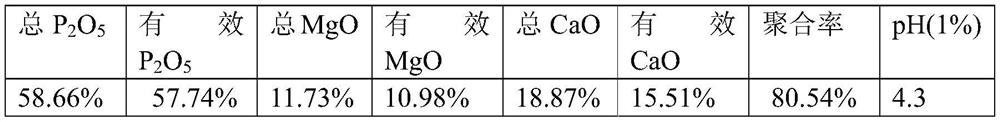

[0040] The product analysis results are as follows:

[0041]

Embodiment 2

[0043] A method for preparing calcium magnesium polyphosphate fertilizer using wet-process phosphoric acid and phosphorus tailings as raw materials, the used raw material indicators are as follows:

[0044] Wet-process phosphoric acid: w(P2O5) 22.39%, w(MgO) 1.23%, w(CaO) 0.15%;

[0045] Phosphorus tailings: w(P2O5)6.18%, w(MgO)15.23%, w(CaO)34.32%;

[0046] Including the following steps:

[0047] (1) 100kg of phosphorus tailings and 520kg of phosphoric acid were mixed and reacted for 2 hours at normal temperature in a reactor to obtain a reaction mixture;

[0048] (2) Concentrating the above reaction mixture at 80°C and 30kPa to a concentrated solution with a mass content of 44-45% of water in the slurry;

[0049] (3) Calcining the concentrated solution obtained above at 450° C. for 3 hours, and then grinding to obtain the calcium magnesium polyphosphate product.

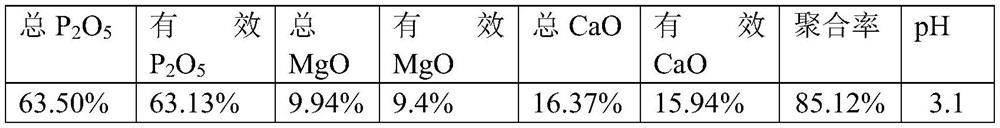

[0050] The product analysis results are as follows:

[0051]

Embodiment 3

[0053] A method for preparing calcium magnesium polyphosphate fertilizer using wet-process phosphoric acid and phosphorus tailings as raw materials, the used raw material indicators are as follows:

[0054] Wet-process phosphoric acid: w(P 2 o 5 ) 22.39%, w (MgO) 1.33%, w (CaO) 0.19%;

[0055] Phosphorus tailings: w(P 2 o 5 ) 7.02%, w (MgO) 17.23%, w (CaO) 33.35%;

[0056] Including the following steps:

[0057] (1) 100kg of phosphorus tailings and 580kg of phosphoric acid were mixed and reacted for 1h at normal temperature in a reactor to obtain a reaction mixture;

[0058] (2) Concentrating the above-mentioned reaction mixture at 90°C and 30kPa to a concentrated solution with a mass content of 35-36% of water in the slurry;

[0059] (3) Calcining the concentrated solution obtained above at 600° C. for 2 hours and grinding to obtain the calcium magnesium polyphosphate product.

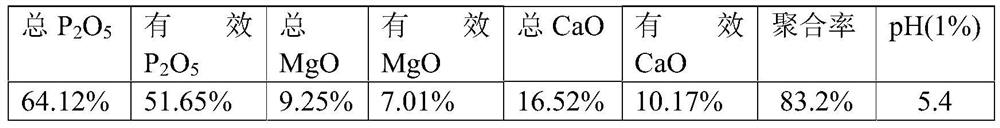

[0060] The product analysis results are as follows:

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com