Low-smoke-amount flame-retardant optical cable factice

A low-smoke, optical cable technology, applied in the field of optical cable materials, can solve the problems of flammable, poisonous smoke and gas, low smoke generation, and low smoke toxicity, etc., and achieve small physical properties, low volatility, timely and efficient flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A low-smoke flame-retardant optical cable ointment, comprising components by mass: 78 parts of base oil, 9 parts of compound thickener, 0.8 part of flame retardant, and 0.5 part of antioxidant.

[0021] The base oil is hydrogenated paraffin base oil / hydrogenated naphthenic oil mixed oil, and the mass ratio is 2:3; the composite thickener is polyacrylamide / fatty alcohol polyoxyethylene ether, and the mass ratio is 5: 7; the flame retardant is triallyl isocyanurate and nano-tin powder, the mass ratio is 90:0.15, wherein triallyl isocyanurate is a thermal crosslinking agent, and nano-tin powder is a catalyst ; The antioxidant is tertiary butyl hydroquinone.

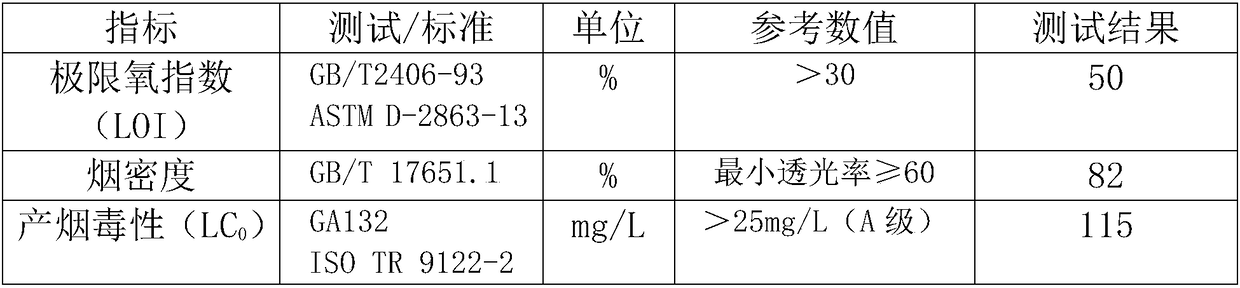

[0022] Example 1 Flame-retardant performance table of low-smoke flame-retardant optical cable ointment:

[0023]

Embodiment 2

[0025] A low-smoke flame-retardant optical cable ointment, comprising components by mass: 80 parts of base oil, 10 parts of compound thickener, 1.1 parts of flame retardant, and 0.6 parts of antioxidant.

[0026] Described base oil is hydrogenated paraffin base oil / hydrogenated naphthenic oil mixed oil, and mass ratio is 2.1:3.4; Described composite thickener is polyacrylamide / fatty alcohol polyoxyethylene ether, and mass ratio is 5.4: 7.3; the flame retardant is triallyl isocyanurate and nano-tin powder, the mass ratio is 93:0.17, wherein triallyl isocyanurate is a thermal crosslinking agent, and nano-tin powder is a catalyst ; The antioxidant is tertiary butyl hydroquinone.

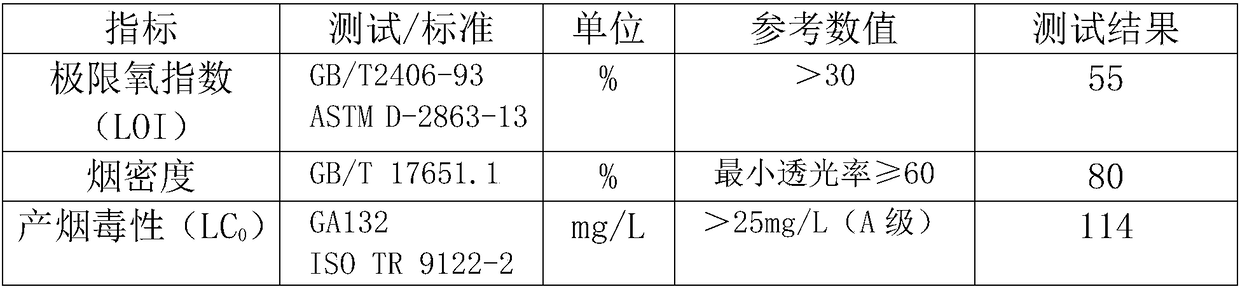

[0027] Example 2 Flame-retardant performance table of low-smoke flame-retardant optical cable ointment:

[0028]

Embodiment 3

[0030] A low-smoke flame-retardant optical cable ointment, comprising components by mass: 82 parts of base oil, 11 parts of compound thickener, 1.3 parts of flame retardant, and 0.7 parts of antioxidant.

[0031] The base oil is hydrogenated paraffinic base oil / hydrogenated naphthenic oil mixed oil, and the mass ratio is 2.3:3-3.8; the composite thickener is polyacrylamide / fatty alcohol polyoxyethylene ether, and the mass ratio is 5.7:7.7; The flame retardant is triallyl isocyanurate and nano tin powder, and the mass ratio is 97:0.19, wherein triallyl isocyanurate is a thermal crosslinking agent, and nano tin powder It is a catalyst; the antioxidant is tertiary butyl hydroquinone.

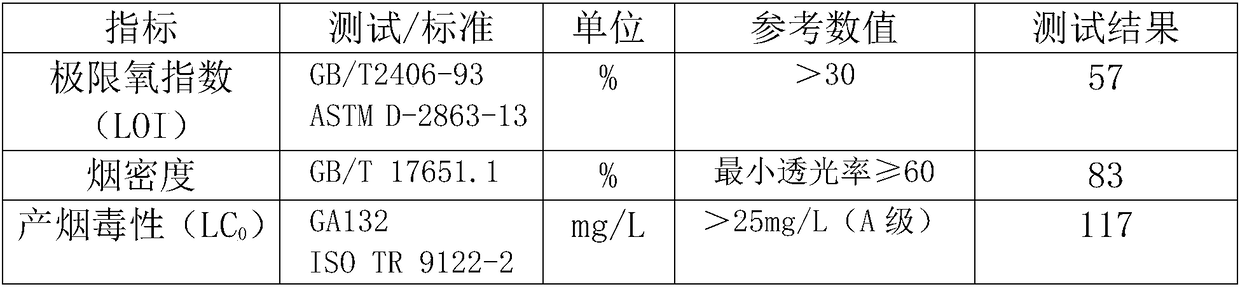

[0032] Example 3 Flame-retardant performance table of low-smoke flame-retardant optical cable ointment:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com