Non-evaporable type air intake agent material applied to high-precision vacuum device

A vacuum device, non-evaporative technology, applied in vacuum evaporation plating, metal material coating process, ion implantation plating, etc., can solve the problem of getter activity disappearance, improve the getter performance and reduce the probability of failure , good vacuum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in further detail below in conjunction with accompanying drawing:

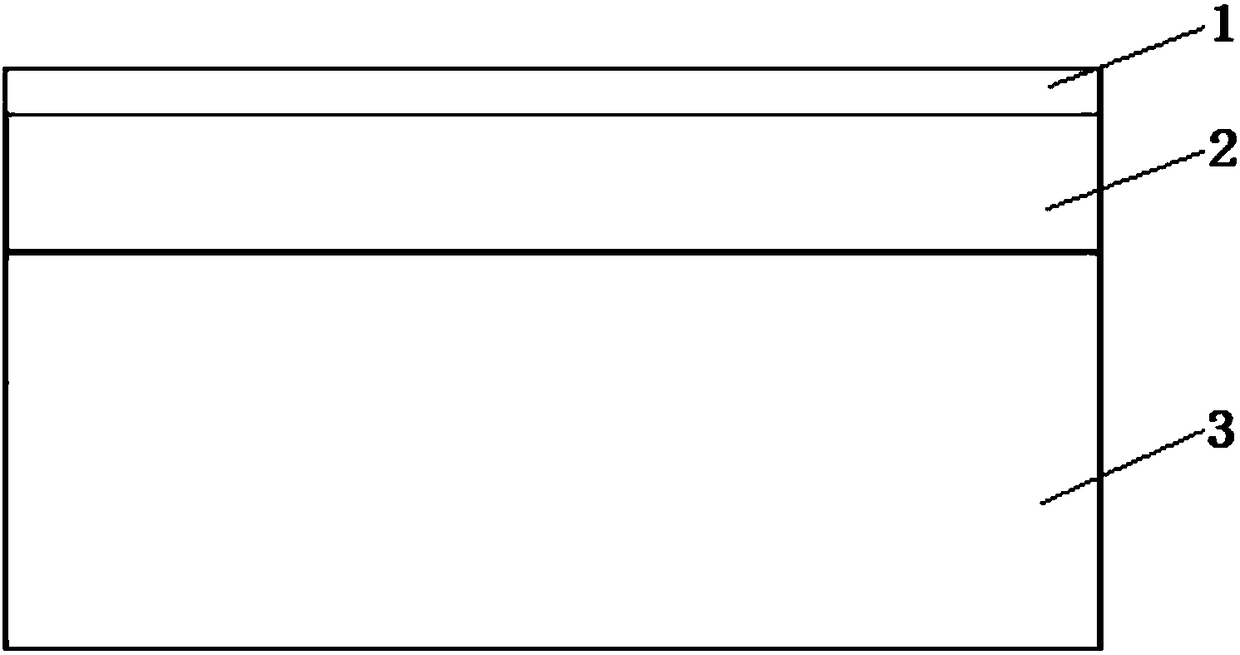

[0012] refer to figure 1 The non-evaporable getter material suitable for high-precision vacuum devices described in the present invention includes a substrate 3, a non-evaporable getter Ti-Zr-V-Hf film 2 and a Pd film distributed sequentially from bottom to top 1, wherein the substrate 3 is stainless steel, oxygen-free copper or silicon wafer.

[0013] The non-evaporable getter Ti-Zr-V-Hf film 2 has a lower activation temperature, which is conducive to expanding the application range of the film, such as the previous non-evaporable getter such as Ti-Zr-V The thin film has an activation temperature of 220°C. Due to the high activation temperature, it cannot be used on the aluminum alloy pipe, which may easily cause deformation of the aluminum alloy pipe, thereby affecting the quality of the particle beam in the aluminum alloy pipe.

[0014] Coating a layer of Pd film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com