Energy-saving and environmentally-friendly dyeing process

An energy-saving, environmental-friendly, and technological technology, applied in the field of textile dyeing and finishing, can solve the problems of large sewage discharge, increased steam consumption, and high post-treatment water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

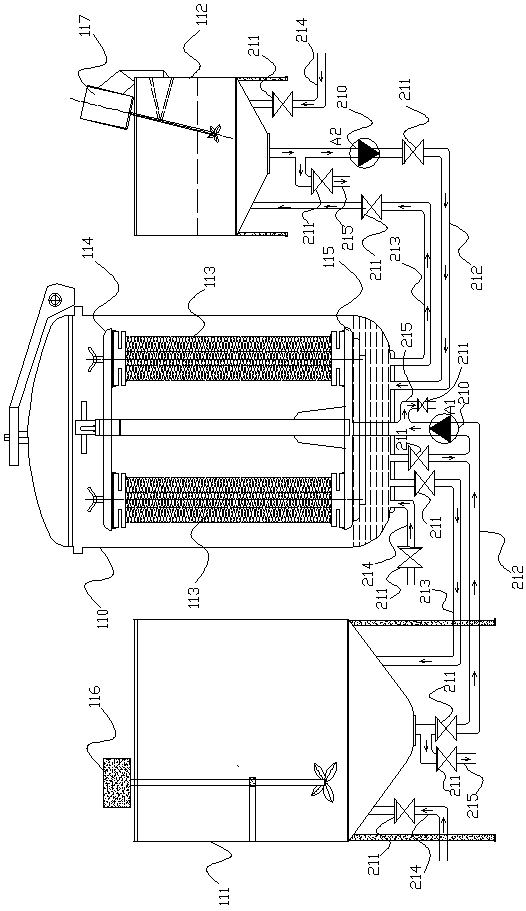

[0029] The dyeing process can be carried out by fixing the dyeing shaft 113 in the inner cavity of the main cylinder 110 through the creel 114 and the creel chassis 115. The whole dyeing process consists of three stages: pre-treatment, dyeing and post-treatment, the specific methods are as follows:

[0030] 1. Pre-processing:

[0031] After the spare tank 111 is filled with water, turn on the spare tank agitator 116, add the oxygen bleaching aid and wait for the mixture to be uniform, then turn on the circulation pump A1, and pump the mixture of the oxygen bleaching aid and water into the main tank 110. Add caustic soda into the material barrel 112 and then inject it into the main vat 110. After running for 3 minutes, add hydrogen peroxide into the material barrel 112 and then inject it into the main vat 110. The above process is carried out in the main vat 110 under normal pressure.

[0032] Then start to pressurize the master cylinder 110 to 2 bar, and raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com