A kind of ship propeller blade with piezoelectric damping and preparation method

A technology for propellers and ships. It is applied in the field of propeller blades and preparations for ships. It can solve the problems of limited damping performance of propeller structure, uncontrollable dynamic mechanical properties, and large impact of resin matrix damping performance by temperature and frequency. vibration and noise reduction performance, and the effect of excellent mechanical properties of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a ship propeller blade with piezoelectric damping, the specific steps are:

[0033] 1. According to the hydrodynamic performance requirements of the propeller, the cladding structure design of the piezoelectric damping composite core and the fiber-reinforced thermoplastic composite prepreg is carried out;

[0034] 2. Determine the proportions of piezoelectric ceramic powder, carbon nanotubes, and thermoplastic polymers in the core of piezoelectric damping composite materials, as well as the types of fiber-reinforced thermoplastic composite materials, according to the design requirements of the cladding structure, and carry out fiber-reinforced thermoplastic composite materials. Dip preparation;

[0035] 3. Cut the fiber-reinforced thermoplastic composite material prepreg to size, and put it into the upper and lower molds by manual method according to the design sequence and layer angle;

[0036] 4. Put the carbon nanotubes into the mixed acid sol...

Embodiment 1

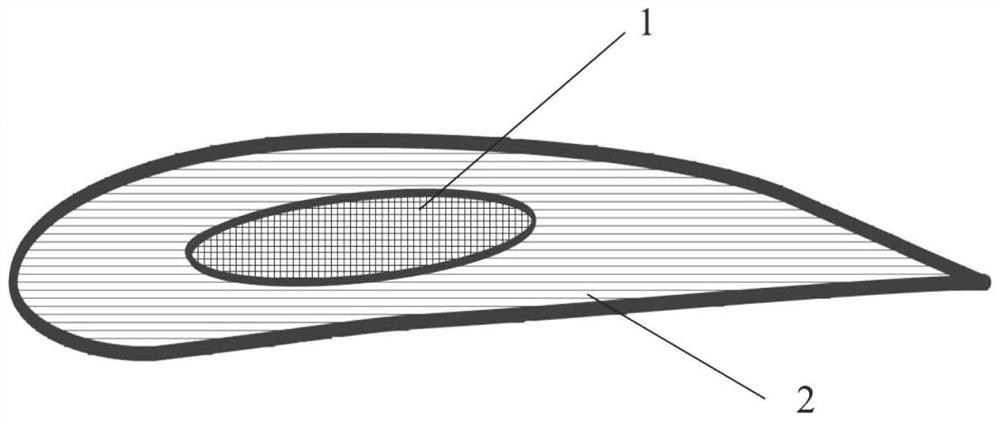

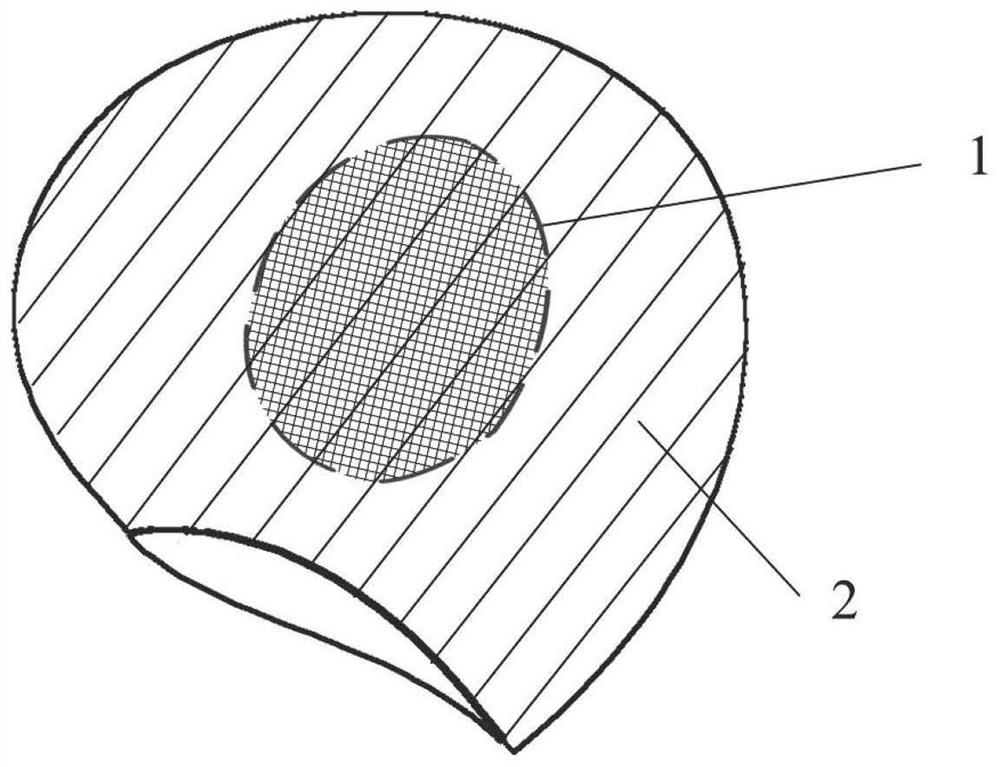

[0042] A propeller blade for ships with piezoelectric damping, made of 80 parts by mass of piezoelectric damping composite material core and 200 parts by mass of T300 carbon fiber reinforced polyamide composite material prepreg cladding;

[0043] The core of the piezoelectric damping composite material is located in the middle of the propeller blade. It is composed of 5 parts by mass of lead dioxide piezoelectric ceramic powder, 0.09 parts by mass of acidified single-walled carbon nanotubes, and 100 parts by mass of polyamide at 210 ° C. After stirring evenly for 30 minutes, pour it into a mold and cool to room temperature to release the mold.

[0044] After the piezo-resistance damping composite material core is obtained, the unidirectional T300 carbon fiber reinforced polyamide composite material prepreg with a thickness of 0.4m is cut, and the side bevel angle of the blade is taken as the reference angle, according to The layup sequence of the piezoelectric damping comp...

Embodiment 2

[0046] A ship propeller blade with piezoelectric damping, made of 120 parts by mass of piezoelectric damping composite material core and 120 parts by mass of T700 carbon fiber reinforced polyether ketone composite material prepreg cladding;

[0047] The core of the piezoelectric damping composite material is located at the root of the propeller blade, and is uniformly prepared by 8 parts by mass of lead zirconate piezoelectric ceramic powder, 0.05 parts by mass of acidified multi-walled carbon nanotubes, and 100 parts by mass of polyether ketone at 230 °C. After stirring for 45 minutes, it was poured into a mold and cooled to room temperature to be released from the mold.

[0048] After the piezoelectric damping composite material core is obtained, the 0.35m thick unidirectional T700 carbon fiber reinforced polyetherketone composite material prepreg is cut, and the blade side bevel angle is used as the reference angle, according to The layup sequence of the piezoelectric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com