Lightweight gypsum board with electromagnetic shielding function and preparation method thereof

An electromagnetic shielding and gypsum board technology, applied in the field of lightweight gypsum board and its preparation, can solve the problems of life, work and electrical equipment hazards, gypsum board does not have electromagnetic shielding and other problems, achieve excellent compatibility between raw materials, and improve indoor life. Or the effect of improving the working environment and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A light-weight gypsum board with electromagnetic shielding function, the preparation raw materials of which include gypsum powder, 32% of fillers and 6% of external additives, wherein the fillers include the following raw materials by weight:

[0048] 1 part of reducing iron powder;

[0049] 4 parts of volcanic ash;

[0050] 2 parts of porous limestone;

[0051] 1 part of expanded graphite;

[0052] 3 parts of palygorskite;

[0053] 2 parts of clinoptilolite;

[0054] 4 parts of bauxite;

[0055] 1.5 parts of aluminized glass fiber;

[0056] Above-mentioned landplaster is obtained by mixing citric acid landplaster and clay landplaster by mass ratio of 2:1;

[0057] The above-mentioned adjuvant includes the following raw materials in parts by weight: 0.6 part of expansion agent, 0.3 part of coupling agent, 3 parts of polymer emulsion, 0.4 part of foaming agent and 0.3 part of coagulation regulator.

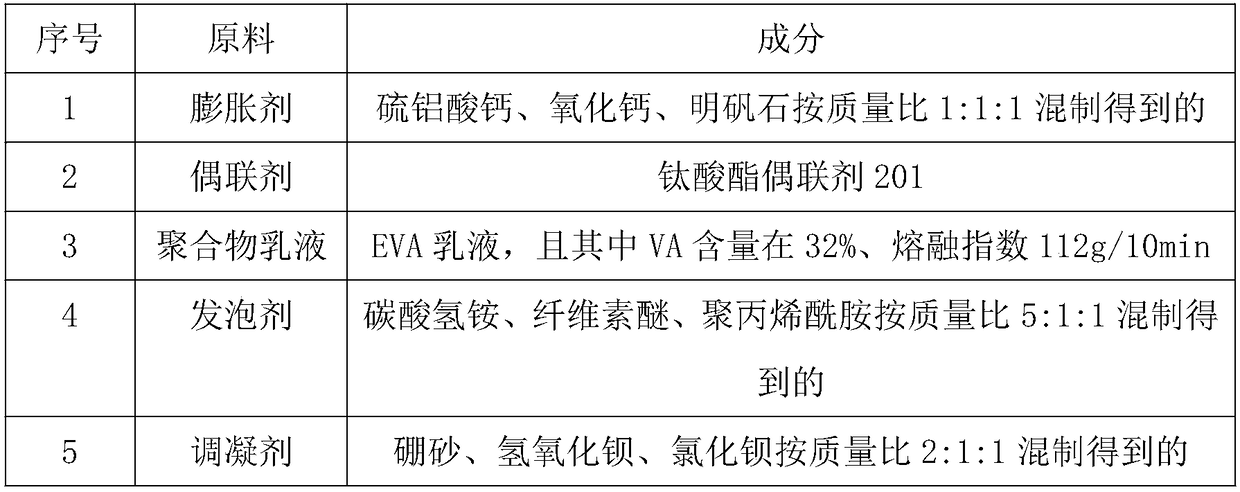

[0058] The above-mentioned various adjuvants are selected as sho...

Embodiment 2

[0070] A light-weight gypsum board with electromagnetic shielding function, the preparation raw materials of which include gypsum powder, 34% of fillers and 7% of external additives, wherein the fillers include the following raw materials by weight:

[0071] 1.5 parts of reducing iron powder;

[0072]5 parts of volcanic ash;

[0073] 2.5 parts of porous limestone;

[0074] 1.25 parts of expanded graphite;

[0075] 4 parts palygorskite;

[0076] 2.5 parts of clinoptilolite;

[0077] 5 parts of bauxite;

[0078] 1.75 parts of aluminized glass fiber;

[0079] Above-mentioned landplaster is obtained by mixing citric acid landplaster and clay landplaster by mass ratio of 2:1;

[0080] The above-mentioned adjuvant includes the following raw materials in parts by weight: 0.7 part of expansion agent, 0.4 part of coupling agent, 4 parts of polymer emulsion, 0.5 part of foaming agent and 0.4 part of coagulation regulator.

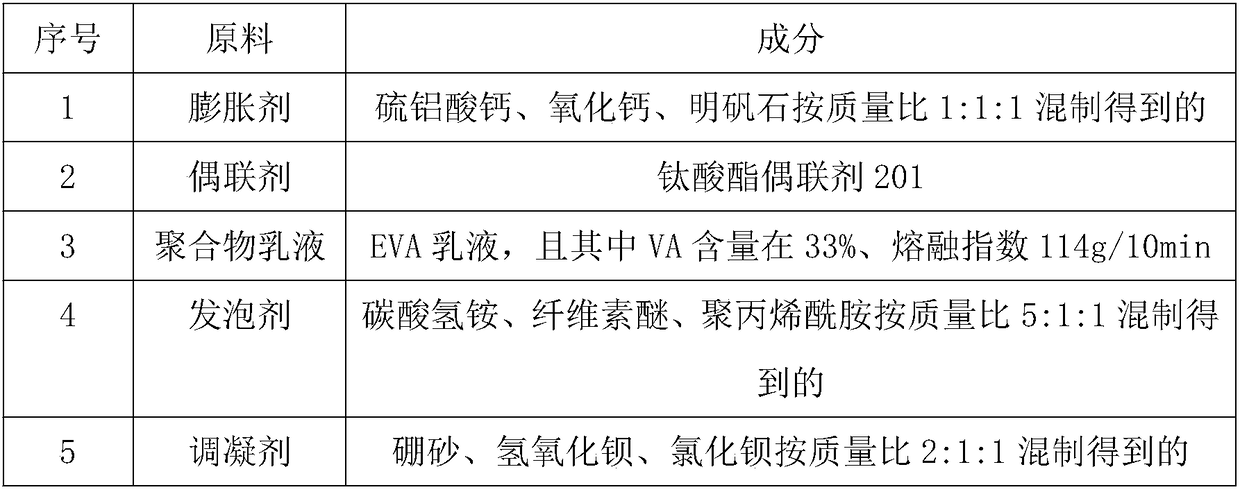

[0081] Above-mentioned each adjuvant is selected as show...

Embodiment 3

[0093] A lightweight gypsum board with electromagnetic shielding function, the preparation raw materials of which include gypsum powder, 36% of fillers and 8% of external additives, wherein the fillers include the following raw materials by weight:

[0094] 2 parts of reducing iron powder;

[0095] 6 parts of volcanic ash;

[0096] 3 parts of porous limestone;

[0097] 1.5 parts of expanded graphite;

[0098] 5 parts of palygorskite;

[0099] 3 parts of clinoptilolite;

[0100] 6 parts of bauxite;

[0101] 2 parts of aluminized glass fiber;

[0102] The above-mentioned landplaster is obtained by mixing citric acid landplaster and clay plaster in a mass ratio of 3:1;

[0103] The above-mentioned adjuvant includes the following raw materials in parts by weight: 0.8 part of expansion agent, 0.5 part of coupling agent, 5 parts of polymer emulsion, 0.6 part of foaming agent and 0.5 part of coagulation regulator.

[0104] Above-mentioned each adjuvant is selected as shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com