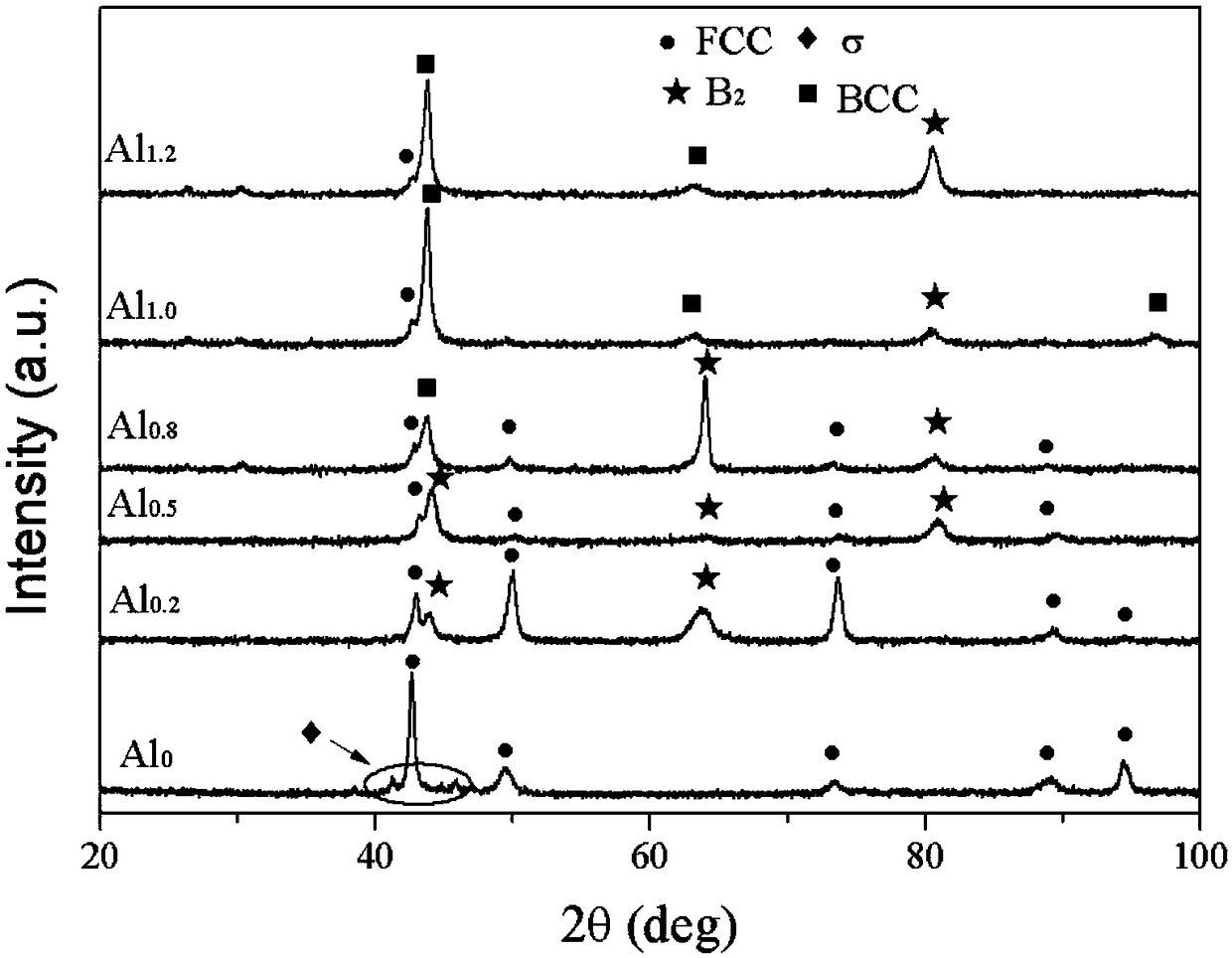

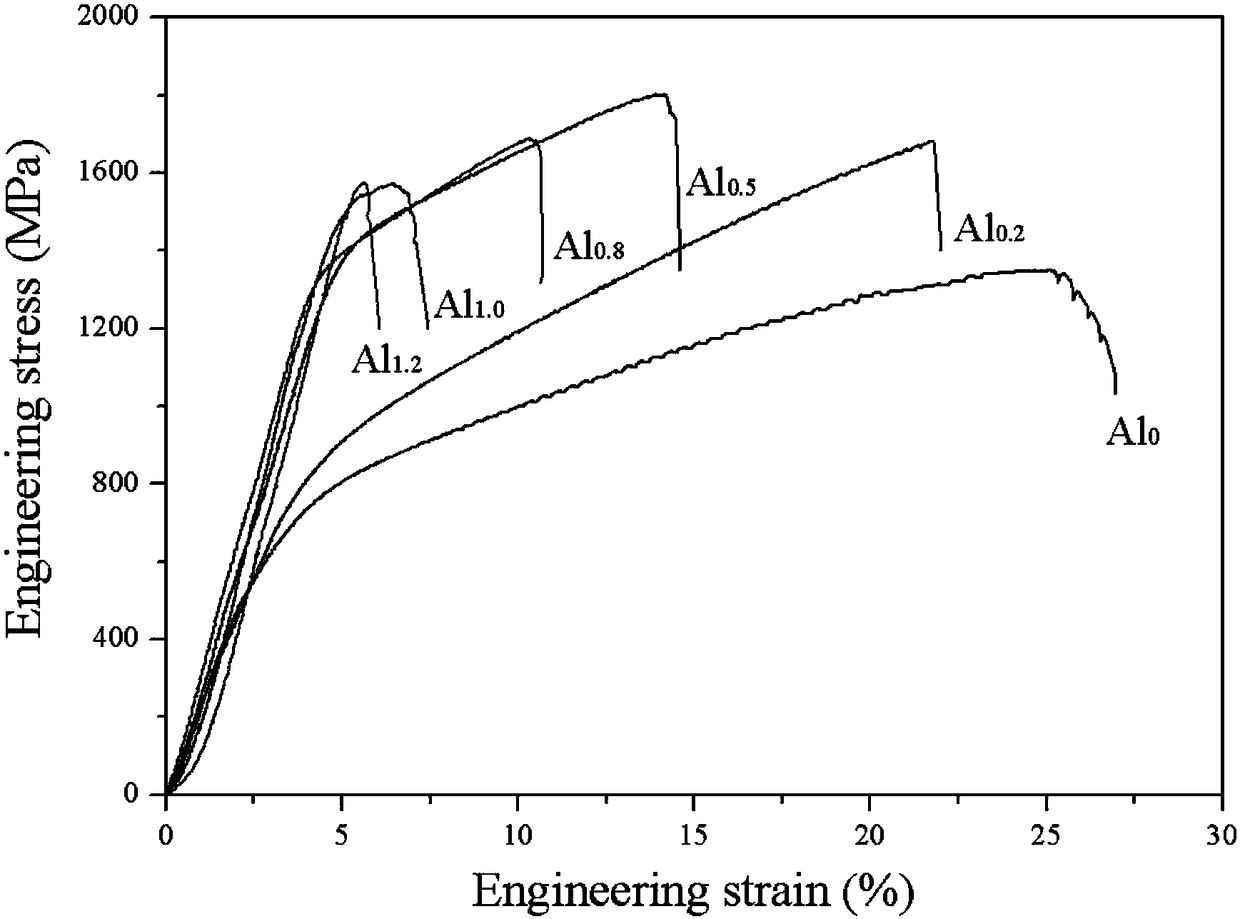

Five-element high-entropy alloy Cu0.5FeNiVAlx and strength and hardness improvement method thereof

A high-entropy alloy, high-strength technology, applied in the field of high-entropy alloys, to achieve the effect of broadening the application range and application prospects, improving performance, and increasing economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A Quaternary High-Entropy Alloy Cu 0.5 For FeNiV, the purity of the alloy raw materials used is ≥99.9%, and the impurities and oxides on the surface of the raw materials are removed by mechanical means, and then cleaned and dried with industrial ethanol, and weighed with an electronic balance according to the ratio shown in Table 1. The weighing error Less than three ten thousandths.

[0039] Table 1: Alloy raw material ratio

[0040] sample

mark

Cu

Fe

Ni

V

Al

Cu 0.5 FeNiV

Al 0

14.29

28.57

28.57

28.57

0

[0041] In this example, WK-Ⅱ type non-consumable vacuum arc melting is used to prepare quaternary high-entropy alloy Cu 0.5 FeNiV, the specific steps are as follows:

[0042] (1) put into water-cooled copper crucible after alloy raw material copper, iron, nickel, vanadium are calculated and weighed according to atomic percentage;

[0043] (2) Turn on the mechanical pump to evacuate the melting furnace ...

Embodiment 2

[0050] A five-element high-entropy alloy Cu 0.5 FeNiVAl 0.2 , the purity of the alloy raw materials used are all ≥99.9%, the impurities and oxides on the surface of the raw materials are removed by mechanical means, and then cleaned and dried with industrial ethanol, and weighed with an electronic balance according to the ratio shown in Table 2, and the weighing error is less than Three out of ten thousand.

[0051] Table 2: Alloy raw material ratio

[0052] sample

mark

Cu

Fe

Ni

V

Al

Cu 0.5 FeNiVAl 0.2

Al 0.2

13.50

27.03

27.03

27.03

5.41

[0053] In this example, WK-II non-consumable vacuum arc melting is used to prepare five-element high-entropy alloy Cu 0.5 FeNiVAl 0.2 ,Specific steps are as follows:

[0054] (1) Put alloy raw material copper, iron, nickel, vanadium, aluminum into water-cooled copper crucible after calculating and weighing according to atomic percentage;

[0055] (2) Turn on the molecula...

Embodiment 3

[0062] A five-element high-entropy alloy Cu 0.5 FeNiVAl 0.5 , the purity of the alloy raw materials used are all ≥99.9%. The impurities and oxides on the surface of the raw materials are removed by mechanical means, and then cleaned and dried with industrial ethanol. The electronic balance is used to weigh according to the ratio shown in Table 3. The weighing error is less than Three out of ten thousand.

[0063] Table 3: Ratio of Alloy Raw Materials

[0064] sample

mark

Cu

Fe

Ni

V

Al

Cu 0.5 FeNiVAl 0.5

Al 0.5

12.50

25.00

25.00

25.00

12.50

[0065] In this example, WK-II non-consumable vacuum arc melting is used to prepare five-element high-entropy alloy Cu 0.5 FeNiVAl 0.5 ,Specific steps are as follows:

[0066] (1) Put alloy raw material copper, iron, nickel, vanadium, aluminum into water-cooled copper crucible after calculating and weighing according to atomic percentage;

[0067] (2) Turn on the mechan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com