Coaxial non-angle pumping detection method and system

A technology of pump detection and included angle, applied in the direction of material excitation analysis, etc., can solve the problems of complex delay line structure and system error, and achieve the effect of convenient measurement, convenient signal reception, and reduced optical path requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

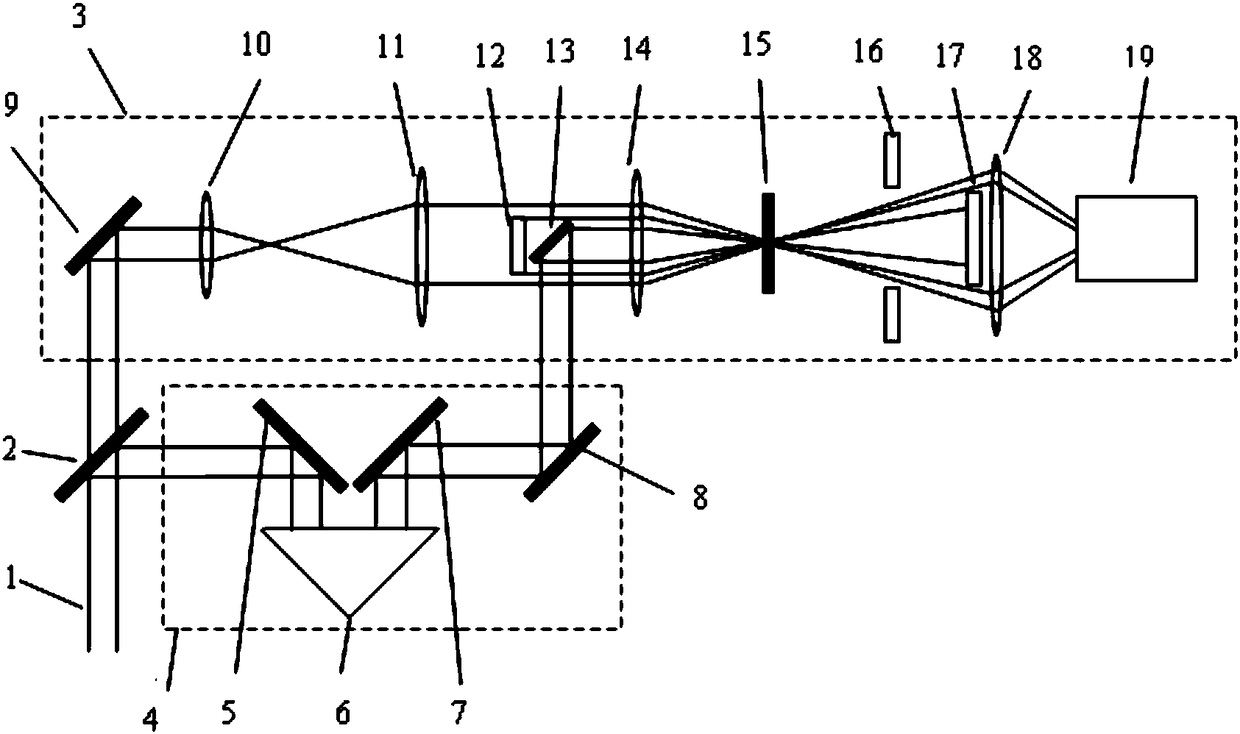

[0029] as attached figure 1As shown, a coaxial pump detection method with no included angle is based on the detection optical path 3 and the pump optical path 4. The pump optical path is composed of reflectors, rectangular prisms, and convex lenses. The reflective prisms can be translated back and forth to change the pumping path. The delay time of light; the detection light path is composed of a reflector, a baffle, a convex lens, a small hole, and a detector; the pump light path and the detection light path are simultaneously focused on the sample to be tested.

[0030] Use the beam splitter 2 to divide the laser pulse 1 into the detection optical path 3 and the pump optical path 4, the detection optical path 3 passes through the mirror 9 to change the direction, after the lens 10 and the convex lens 11 expand the beam, it is blocked by the baffle 12 coaxial with the beam. After light, the edge light beam passes through the pump light reflector 13, then passes through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com