Perovskite solar energy cell based on two-dimensional transition metallic carbide or nitride and preparation method of perovskite solar energy cell

A solar cell, transition metal technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor stability and low conductivity of FTO transparent electrodes, and achieve the effect of good conductivity and enhanced conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An implementation example of using two-dimensional carbide or nitride as the counter electrode of a perovskite solar cell. Take 1g Ti 3 AlC 2The powder was slowly added to 30mL HF (20wt%), stirred and etched for 12h, centrifuged at 3500rpm for 5min, and the precipitate was washed 4-5 times with deionized water until the pH>5, and the obtained two-dimensional carbides or nitrides such as figure 1 As shown, Ti 3 AlC 2 The intermediate connecting layer in the powder has been consumed by the reactants. Stir intercalation in DMSO solution for 3h, Ti 3 C 2 : DMSO=1:50 (mass ratio), then centrifuged at 8000rpm for 5min to remove excess DMSO, washed 4-5 times with deionized water, and the intercalated Ti 3 C 2 Sonicate with water at a mass ratio of 1:50 at a power of 250W for 1h, centrifuge at 3500rpm for 1h, take the upper suspension, filter it with suction, and dry it in vacuum to obtain a few-layer Ti 3 C 2 , the exfoliated two-dimensional carbide or nitride materi...

Embodiment 2

[0033] An implementation example of using two-dimensional carbide or nitride as the hole transport layer material of a perovskite solar cell. Take 5gTi 3 AlC 2 The powder was slowly added to 60mL HF (10wt%), stirred and etched for 20h, centrifuged at 5000rpm for 5min, and the precipitate was washed 4-5 times with deionized water until the pH>5, and the obtained two-dimensional carbide or nitride. Stir intercalation in DMSO solution for 8h, Ti 3 C 2 : DMSO=1:25 (mass ratio), then centrifuged at 8000rpm for 10min to remove excess DMSO, washed 2 times with deionized water, and the intercalated Ti 3 C 2 Sonicate with water at a mass ratio of 1:50 at a power of 250W for 1h, centrifuge at 3500rpm for 1h, take the upper suspension, and dry it in vacuum to obtain a few-layer Ti 3 C 2 , two-dimensional carbide or nitride material after exfoliation.

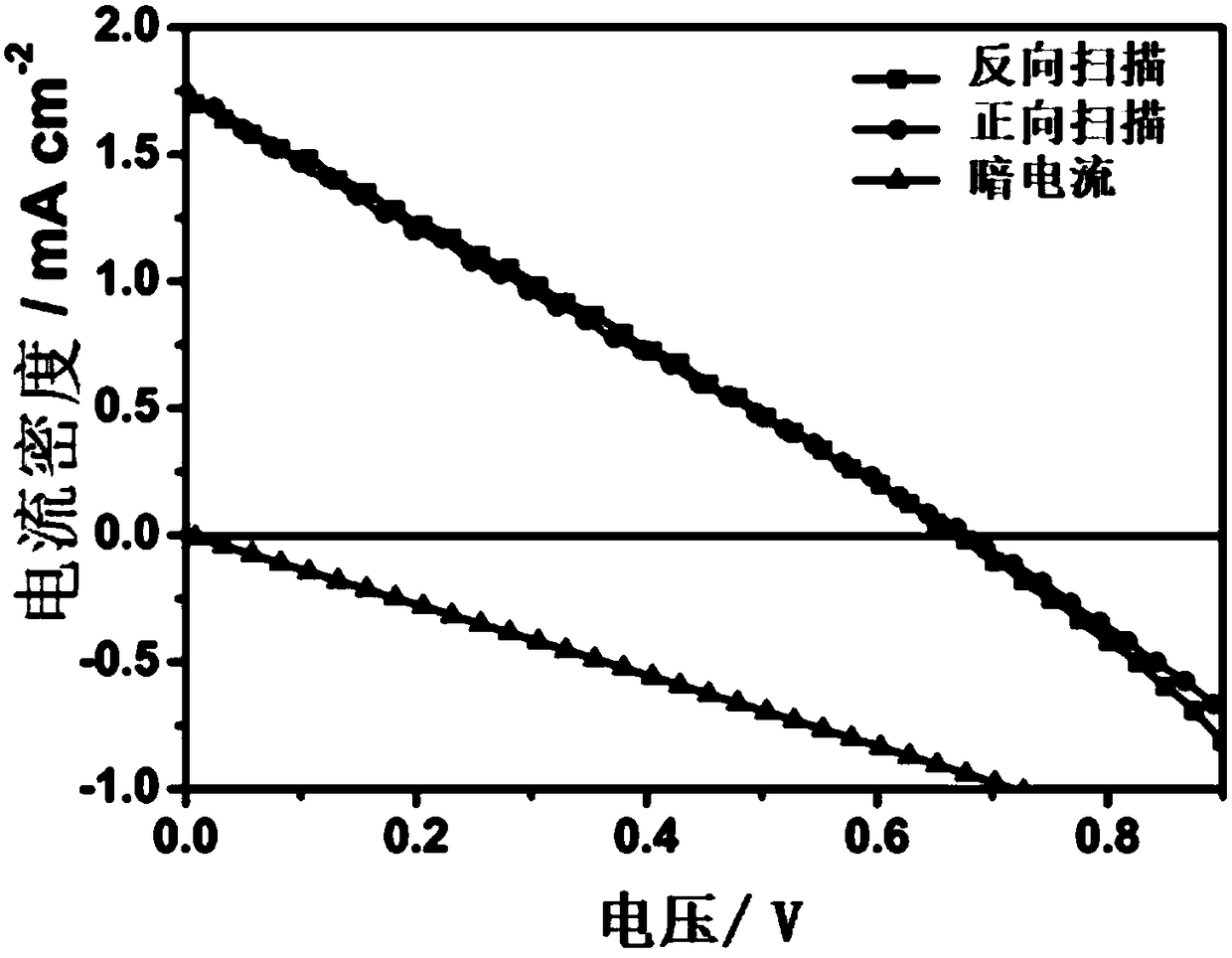

[0034] The device preparation of perovskite solar cells is as follows: on the surface of the substrate, spin-coat 70 μL of dense ...

Embodiment 3

[0036] An implementation example of using two-dimensional carbide or nitride as the doped hole transport layer of a perovskite solar cell. The preparation process of the two-dimensional carbide or nitride material is shown in Example 2. The device preparation of perovskite solar cells is as follows: on the surface of the substrate, spin-coat 70 μL of dense layer TiO 2 , high temperature sintering. 75 μL of porous layer slurry was dropped on TiO 2 On the dense layer, spin-coat at 3000rpm for 30s, and sinter at high temperature. After cooling down, transfer to the glove box and take 55 μL of filtered PbI 2 The solution was dropped on the porous TiO 2 Spin-coat at 3000rpm for 30s, after standing for 10min, 250μL filtered CH 3 NH 3 A solution of I in isopropanol was dropped on PbI 2 Spin-coat at 5000rpm for 30s, and anneal at 165°C for 27.5min on a hot plate. Take 150 μL Ti 3 C 2 Chlorobenzene solution, it is added to the configured Spiro-MeOTAD chlorobenzene solution (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com