Catalytic rectifying apparatus for splitting chirality 1-phenethyl alcohol by virtue of lipase and method for producing chirality 1-phenethyl

A technology of catalytic rectification and phenylethanol, applied in enzyme production/bioreactors, biochemical equipment and methods, fractionation, etc., can solve problems such as difficult to obtain high product conversion rate, achieve reduced contact time and high optical purity , the effect of high reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

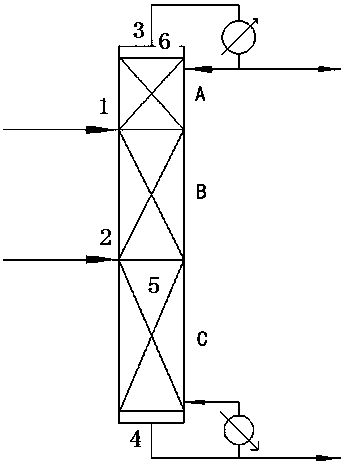

Image

Examples

Embodiment 1

[0030] The operating pressure of the catalytic rectification column used was 300 mBar. 1-Phenylethyl alcohol is continuously fed from the upper feed port of the reaction section after being preheated to 60°C. Ethyl butyrate is continuously fed from the feed port at the lower part of the reaction section after being preheated to 60°C. The molar ratio of feed 1-phenylethanol to ethyl butyrate is 1:3. 1-phenylethanol and ethyl butyrate react under the catalysis of the lipase catalyst loaded in the reaction section to generate R-ester and ethanol. The temperature of the tower kettle is 109-110°C, and the tower kettle reboiler provides the rising gas phase for the upper sections. The top reflux ratio of the catalytic rectification tower is 2.0, the temperature is 50-51°C, and the ethanol product is extracted from the top.

[0031] After testing, the conversion rate of R-1-phenylethanol in the catalytic rectification tower is ≥99.0%, the mass fraction of ethanol in the production ...

Embodiment 2

[0033] The operating pressure of the catalytic rectification column used was 500 mBar. 1-Phenylethyl alcohol is continuously fed from the upper feed port of the reaction section after being preheated to 60°C. Methyl butyrate is fed continuously from the feed port at the lower part of the reaction section after being preheated to 60°C. The molar ratio of feed 1-phenylethanol to methyl butyrate is 1:2. 1-phenylethanol and methyl butyrate react under the catalysis of the lipase catalyst loaded in the reaction section to generate R-ester and methanol. The temperature of the tower kettle is 94-95°C, and the tower kettle reboiler provides the ascending gas phase for the upper sections. The top reflux ratio of the catalytic rectification tower is 2.4, the temperature is 47-48°C, and the methanol product is extracted from the top.

[0034] After testing, the conversion rate of R-1-phenylethanol in the catalytic rectification tower is ≥ 99.5%, the mass fraction of methanol in the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com