Set system for removing PM 2.5 by wet method and recovering waste heat

A waste heat recovery and complete system technology, which is applied in the field of energy conservation and environmental protection, can solve the problems of general dust removal effect of industrial waste gas, achieve good economy, prevent secondary dust, and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

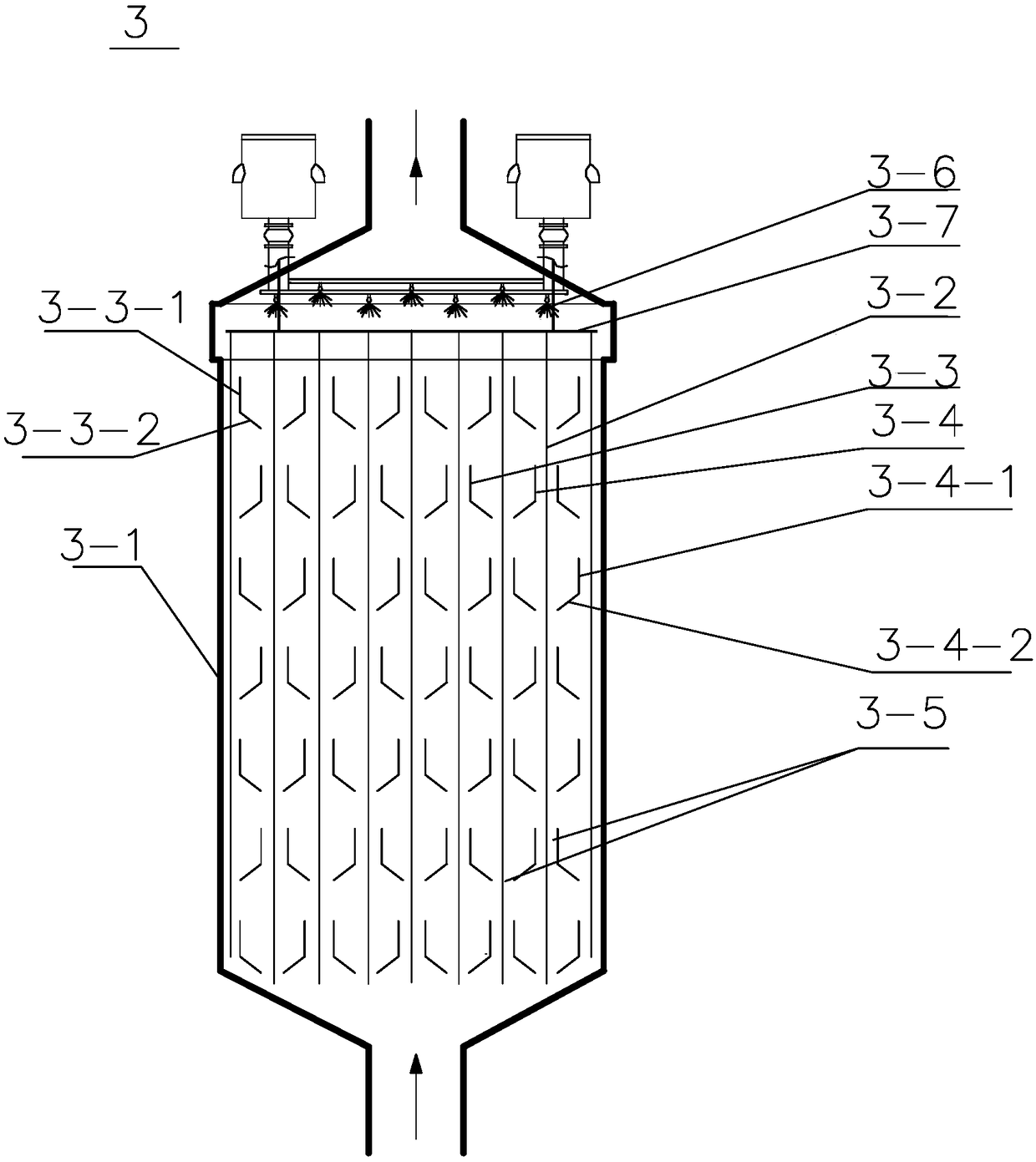

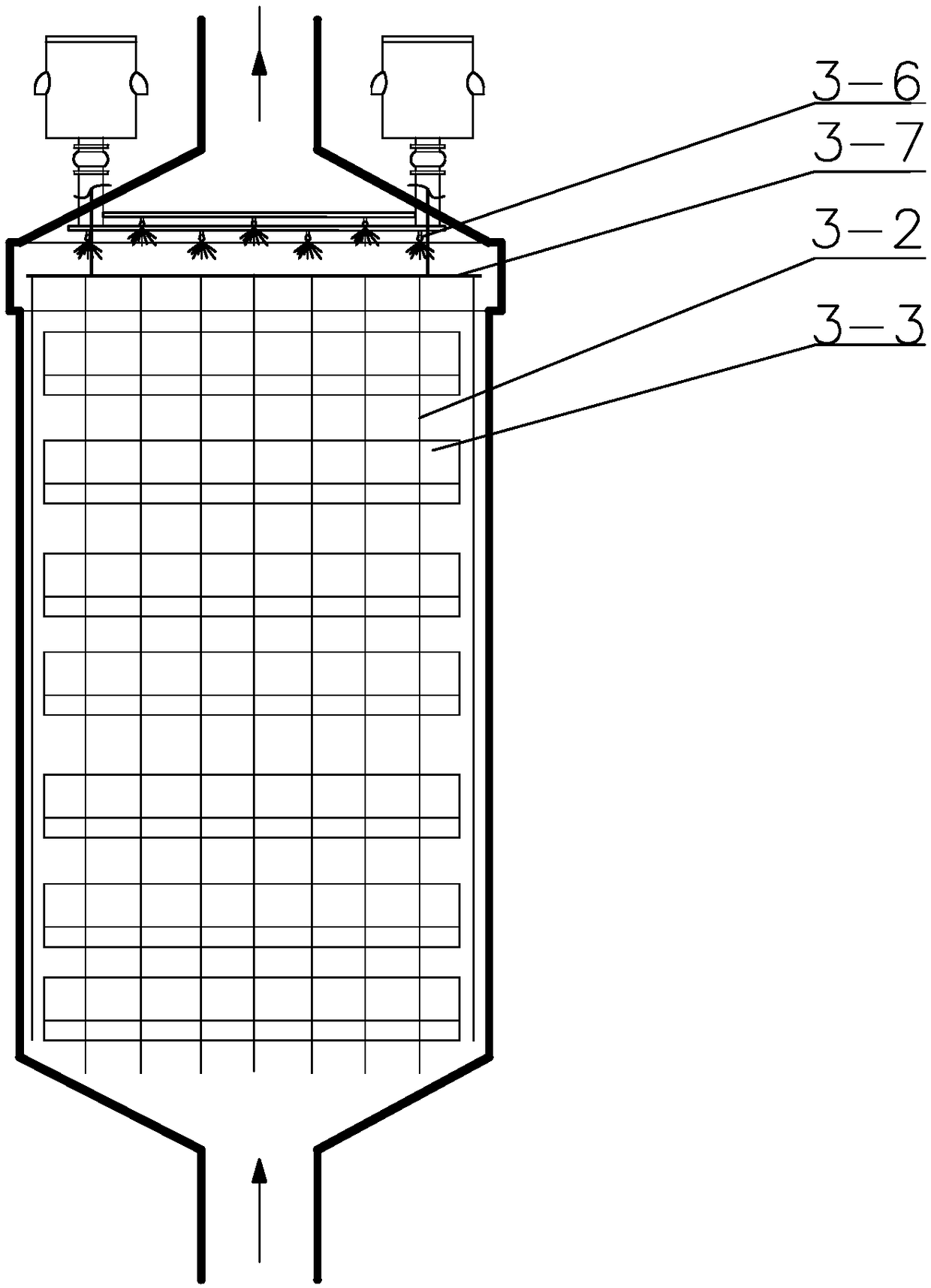

[0021] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

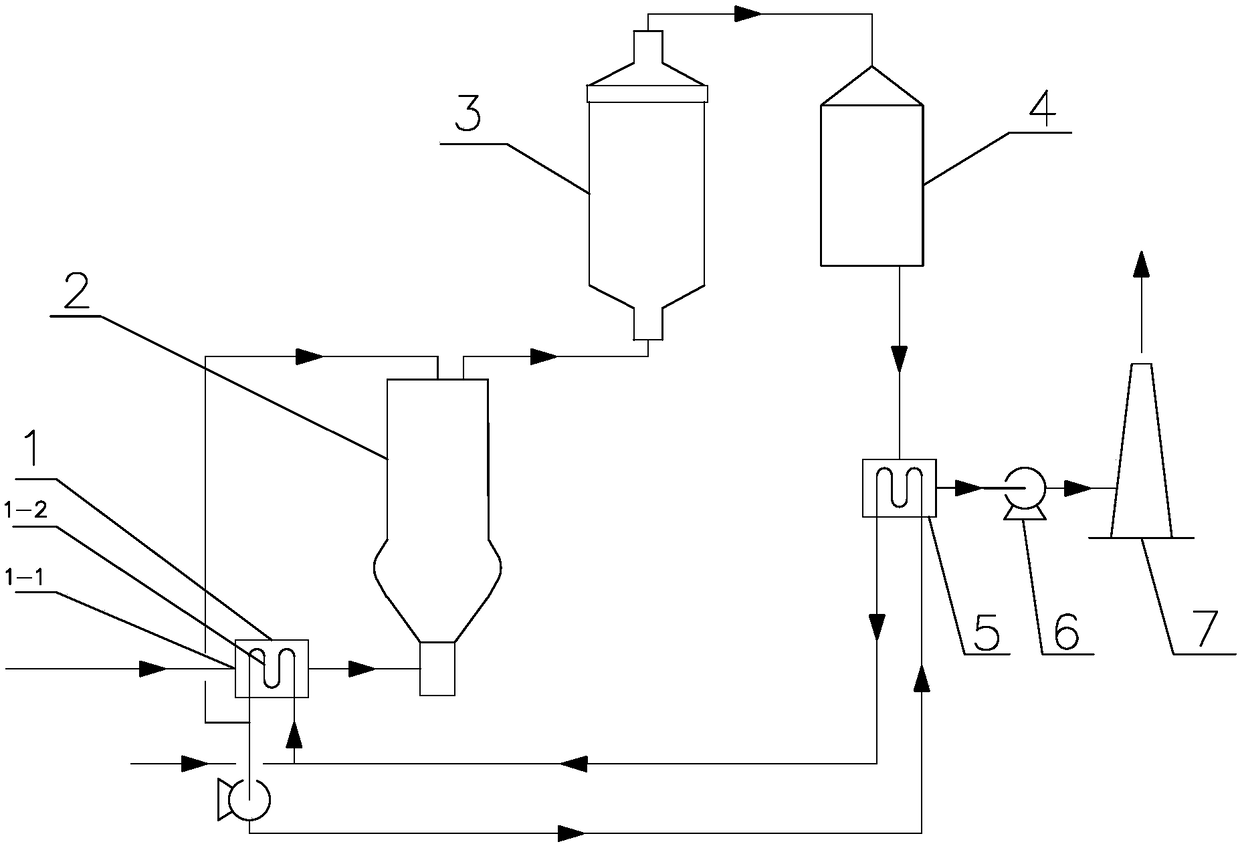

[0022] Such as Figure 1-6 As shown, it is the best embodiment of the present invention, a complete system for wet removal of PM2.5 and waste heat recovery and utilization, including exhaust gas cooler 1, water vapor phase change condensing chamber arranged in series from front to back according to the process sequence 2. Electrostatic precipitator 3, desulfurization tower 4, exhaust gas reheater 5, induced draft fan 6 and chimney 7, exhaust gas cooler 1 is provided with exhaust gas inlet 1-1, and exhaust gas cooler 1 is provided with heat exchanger 1-2 , the electrostatic precipitator 3 is a vertical conical electrostatic precipitator, the vertical conical e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com