Preparation method of Co/Ni-MoO2 composite electrolyzed water catalyst

A technology for catalyst and water electrolysis, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low catalyst yield and complex catalyst preparation methods, and achieve the effect of simple and easy-to-operate preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

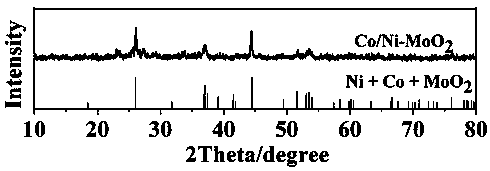

[0019] Firstly, 2.0 mmol each of cobalt nitrate, nickel nitrate, ammonium molybdate, and F127 were weighed in a mortar, mixed and ground for 20 minutes at room temperature to obtain a dough-like precursor. The above precursor was transferred to a muffle furnace, heated at 70 degrees Celsius for 5 hours in an air atmosphere, then raised to 300 degrees Celsius for 1 hour, and then cooled to room temperature naturally to obtain Co / Ni-MoO 2 Composite water electrolysis hydrogen production catalyst.

Embodiment 2

[0021] Firstly, 2.0 mmol each of cobalt nitrate, nickel nitrate, ammonium molybdate, and F127 were weighed in a mortar, mixed and ground for 20 minutes at room temperature to obtain a dough-like precursor. Transfer the above precursor to a muffle furnace, and heat it at 80 degrees Celsius for 8 hours in an air atmosphere, then raise the temperature to 300 degrees Celsius for 1 hour and then cool it down to room temperature naturally to obtain Co / Ni-MoO 2 Composite water electrolysis hydrogen production catalyst.

Embodiment 3

[0023] Firstly, 3.0 mmol each of cobalt nitrate, nickel nitrate, ammonium molybdate and F127 were weighed in a mortar, mixed and ground at room temperature for 20 minutes to prepare a dough-like precursor. The above precursor was transferred to a muffle furnace, heated at 70 degrees Celsius for 8 hours in an air atmosphere, then raised to 300 degrees Celsius for 1 hour and then cooled to room temperature naturally to obtain Co / Ni-MoO 2 Composite water electrolysis hydrogen production catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com