Fiber-reinforced renewable concrete and preparation method thereof

A technology of recycled concrete and fiber reinforcement, applied in the field of recycled concrete, can solve the problems of reduced performance of recycled aggregate, unsatisfactory degree of improvement, small amount of recycled aggregate added, etc., and achieves the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

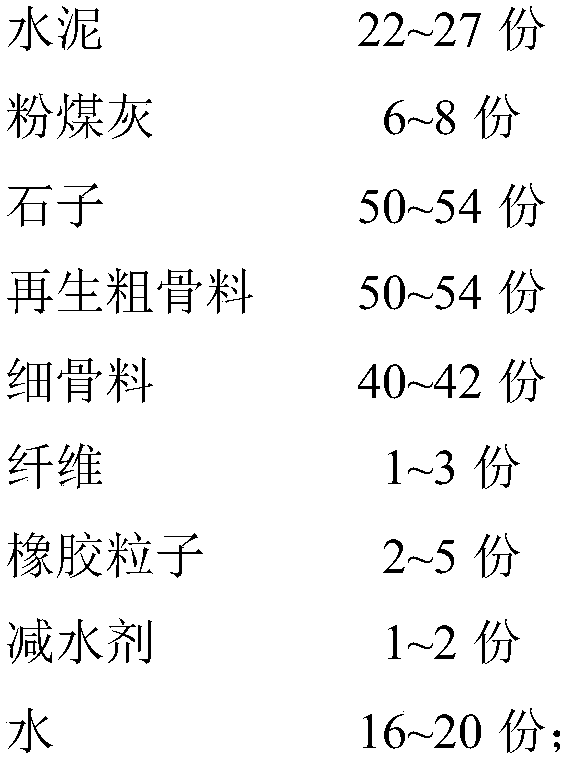

[0033] The formula of fiber reinforced recycled concrete is as follows (by weight):

[0034]

[0035]

[0036] Among them, in the composition of recycled coarse aggregate, the mass ratio of recycled coarse aggregate made from the first to fourth types of waste concrete is 3:10:4:2; in the composition of recycled fine aggregate, the mass ratio of recycled fine aggregate is from the first to fourth types of waste concrete. The mass ratio of recycled fine aggregate made from the fourth type of waste concrete is 1:5:8:2; the composite fiber is composed of polypropylene fiber and glass fiber in a mass ratio of 10:3.

[0037] Preparation method: The waste concrete is crushed with a crusher and sieved to obtain recycled coarse aggregate and recycled fine aggregate. The particle size range of the recycled coarse aggregate is 6-18 μm, and the particle size range of the recycled fine aggregate is 2- 4 μm. Weigh each raw material in the formula amount, add polypropylene fiber, san...

Embodiment 2

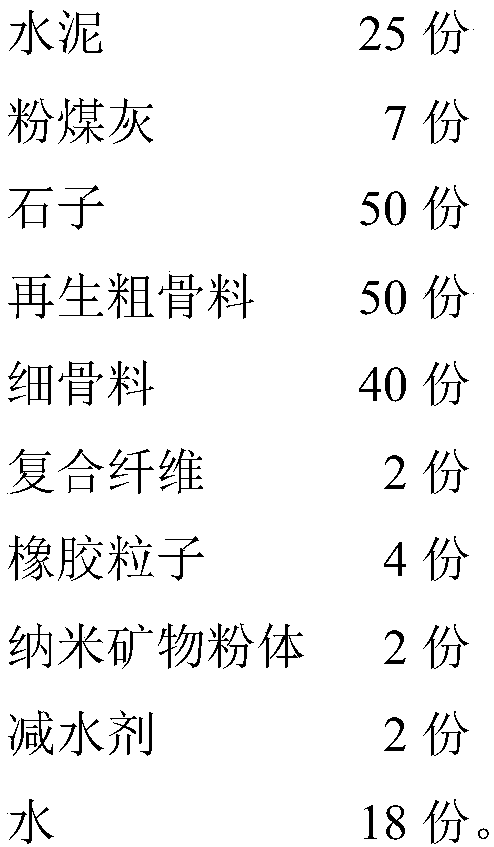

[0039] The formula of fiber reinforced recycled concrete is as follows (by weight):

[0040]

[0041] Among them, in the composition of recycled coarse aggregate, the mass ratio of recycled coarse aggregate made from the first to fourth types of waste concrete is 3:10:4:2; in the composition of recycled fine aggregate, the mass ratio of recycled fine aggregate is from the first to fourth types of waste concrete. The mass ratio of recycled fine aggregate made from the fourth type of waste concrete is 1:5:8:2; the composite fiber is composed of polypropylene fiber, aluminum silicate fiber and glass fiber in a mass ratio of 10:6:3.

[0042] Preparation method: The waste concrete is crushed with a crusher and sieved to obtain recycled coarse aggregate and recycled fine aggregate. The particle size range of the recycled coarse aggregate is 6-18 μm, and the particle size range of the recycled fine aggregate is 2- 4 μm. Weigh each raw material in the formula amount, add composite...

Embodiment 3

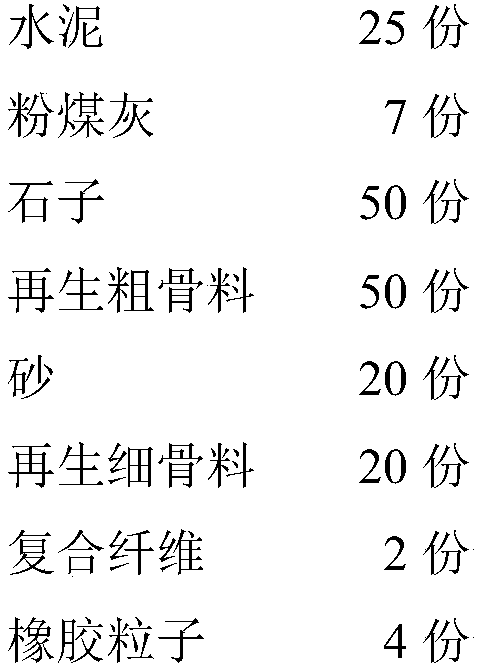

[0044] The formula of fiber reinforced recycled concrete is as follows (by weight):

[0045]

[0046] Among them, in the composition of recycled coarse aggregate, the mass ratio of recycled coarse aggregate made from the first to fourth types of waste concrete is 3:10:4:2; in the composition of recycled fine aggregate, the mass ratio of recycled fine aggregate is from the first to fourth types of waste concrete. The mass ratio of recycled fine aggregate made from the fourth type of waste concrete is 1:5:8:2; the composite fiber is composed of polypropylene fiber, aluminum silicate fiber and glass fiber in a mass ratio of 10:6:3; The mineral powder is composed of nano sepiolite and nano kaolin with a mass ratio of 1:3.

[0047] Preparation method: The waste concrete is crushed with a crusher and sieved to obtain recycled coarse aggregate and recycled fine aggregate. The particle size range of the recycled coarse aggregate is 6-18 μm, and the particle size range of the recycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com