Method for extracting phenolic compounds from coal tar by utilizing ethanolamine

A technology for phenolic compounds and ethanolamines, which can be used in the preparation of organic compounds, chemical instruments and methods, and tar processing through selective solvent extraction, and can solve problems such as unsuitable development of phenolic extraction and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

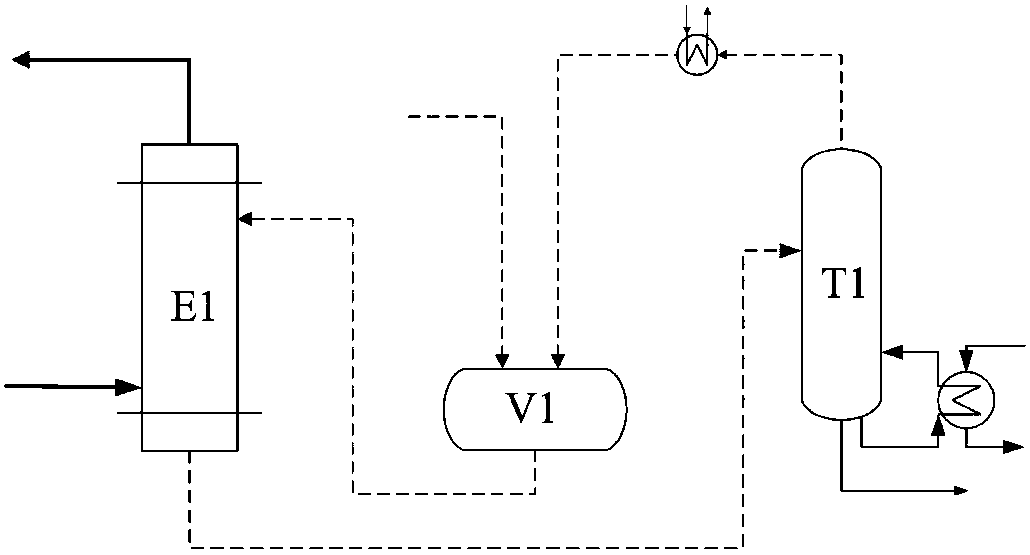

Image

Examples

Embodiment 1

[0023] Embodiment 1 extracts phenolic compounds from low temperature coal tar

[0024] The raw materials are taken from Hebei Longcheng Coal Comprehensive Utilization Co., Ltd.

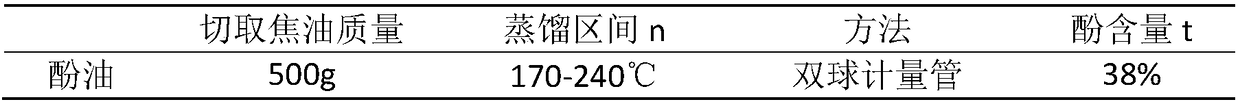

[0025] The coal tar in the 170-230°C fraction was tested for phenol content (double-ball measurement method), and the results are shown in Table 1:

[0026] Table 1: Results of phenol content in coal tar

[0027]

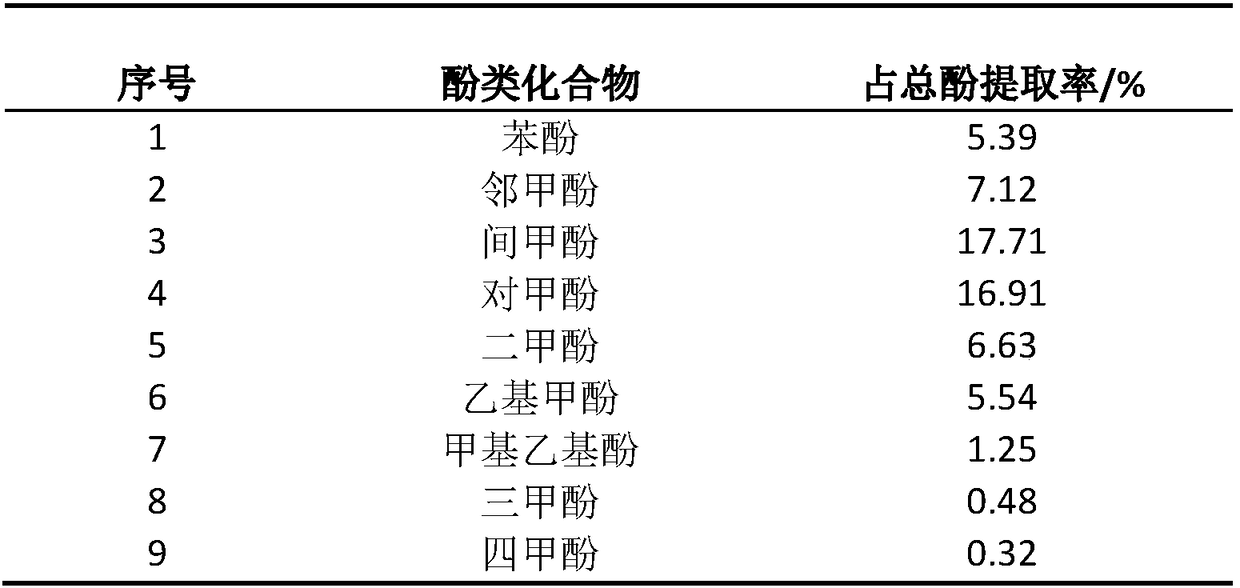

[0028] In the laboratory, add 20g of extractant (ethanolamine) into the separatory funnel, then add 10g of phenol oil, react at 50°C for 30 minutes, stand to separate layers, take out the obtained lower layer, and pass the upper layer through Multi-stage extraction, the extract and the lower layer are mixed together as a mixture of phenol oil and extractant, placed in a three-necked flask, and then ethanolamine is evaporated by distillation to obtain 19g of ethanolamine, and then the lower layer of phenol oil is passed through GC- MS analysis, qualitative and quantitative analysis of t...

Embodiment 2

[0033] Embodiment 2 extracts phenolic compounds from low temperature coal tar

[0034] The raw materials are taken from Hebei Longcheng Coal Comprehensive Utilization Co., Ltd.

[0035] The coal tar in the 170-230°C fraction was tested for phenol content (double-ball measurement method), and the results are shown in Table 1:

[0036] Table 1: Results of phenol content in coal tar

[0037]

[0038] In the laboratory, add 30 g of extractant (ethanolamine) to the separatory funnel, then add

[0039] 10g of phenol oil was reacted at 60°C for 40min, allowed to stand and separated, and the obtained lower layer liquid was taken out, and the upper layer liquid was subjected to multi-stage extraction, and the extract and the lower layer liquid were mixed together as a mixture of phenol oil and extractant. Placed in a three-necked flask, and then distilled out ethanolamine by distillation to obtain 29g of ethanolamine, then the lower layer of phenol oil was analyzed by GC / MS, and t...

Embodiment 3

[0043] Embodiment 3 extracts phenolic compounds from low temperature coal tar

[0044] The raw materials are taken from Hebei Longcheng Coal Comprehensive Utilization Co., Ltd.

[0045] The coal tar in the 170-230°C fraction was tested for phenol content (double-ball measurement method), and the results are shown in Table 1:

[0046] Table 1: Results of phenol content in coal tar

[0047]

[0048] In the laboratory, add 50 g of extractant (ethanolamine) to the separatory funnel, then add

[0049] 10g of phenol oil was reacted at 65°C for 60min, allowed to stand for stratification, and the obtained lower layer liquid was taken out, and the upper layer liquid was subjected to multi-stage extraction, and the extract and the lower layer liquid were mixed together as a mixture of phenol oil and extractant. Placed in a three-necked flask, and then distilled out ethanolamine by distillation to obtain 49g of ethanolamine, then the phenol oil in the lower layer was analyzed by GC / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com