Preparation process for deflazacort

A preparation process, the technology of deflazacort, applied in the field of deflazacort preparation process, can solve the problems of high production cost, complicated process operation, difficult sewage treatment, etc., and achieve simple production operation, economical and environmentally friendly process, and product yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

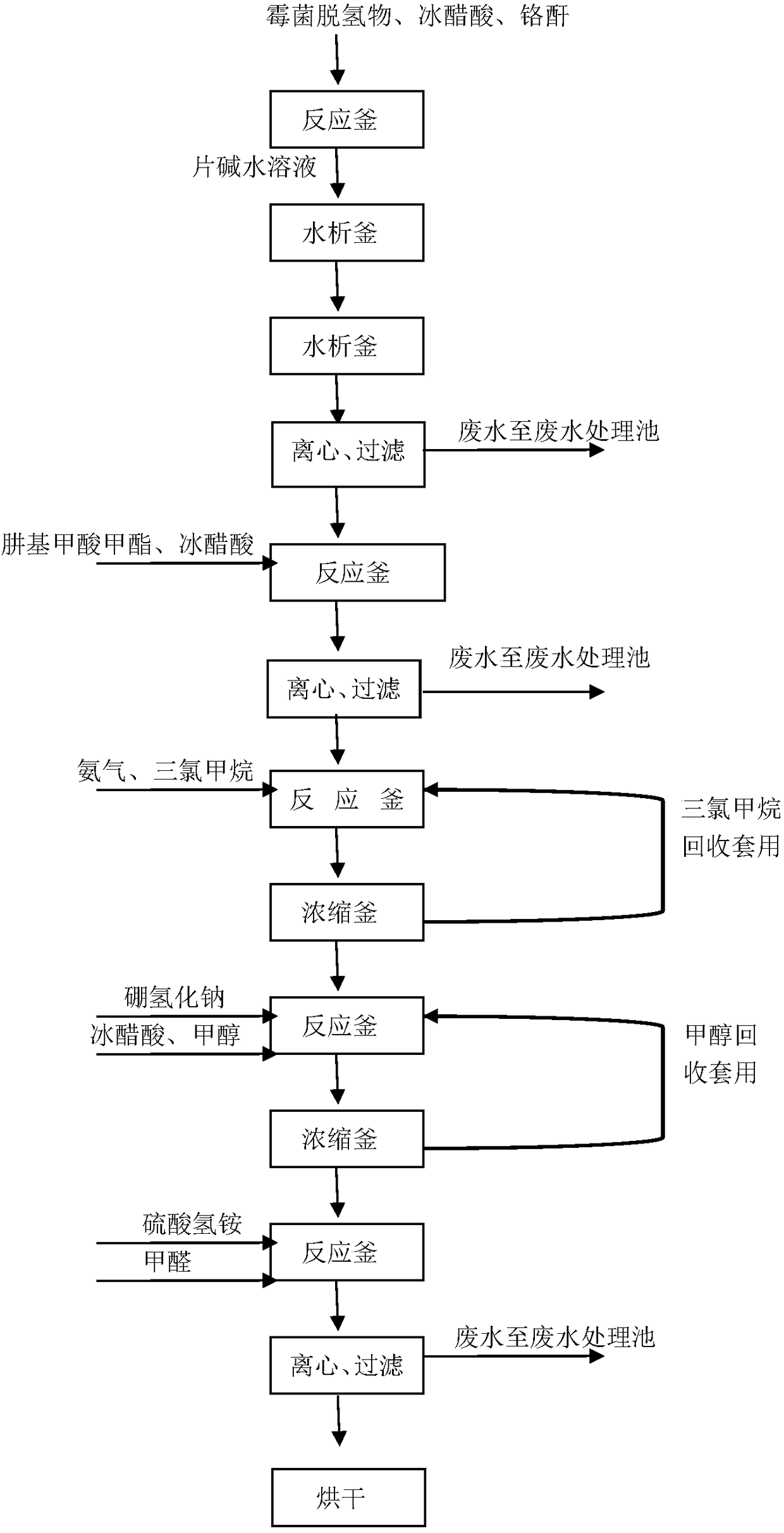

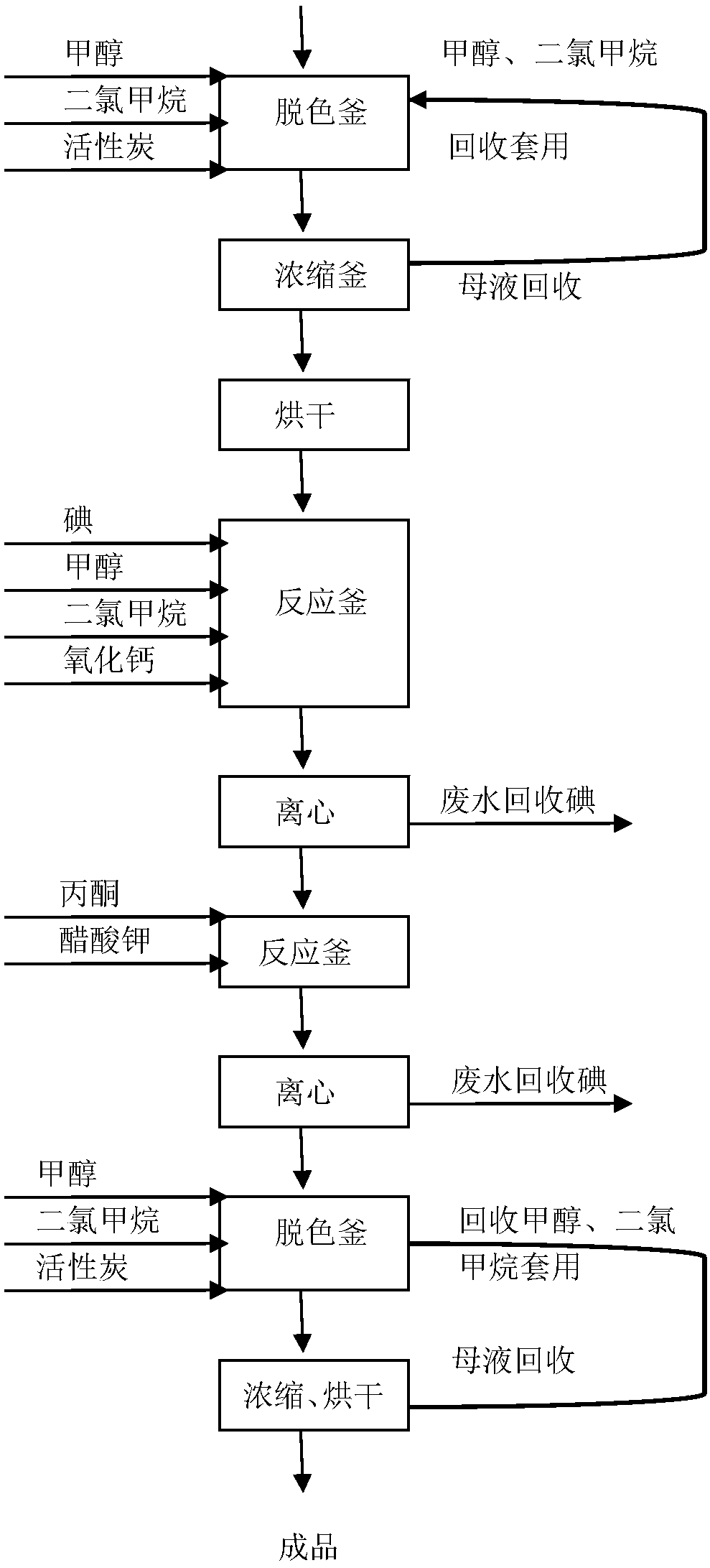

Method used

Image

Examples

Embodiment 1

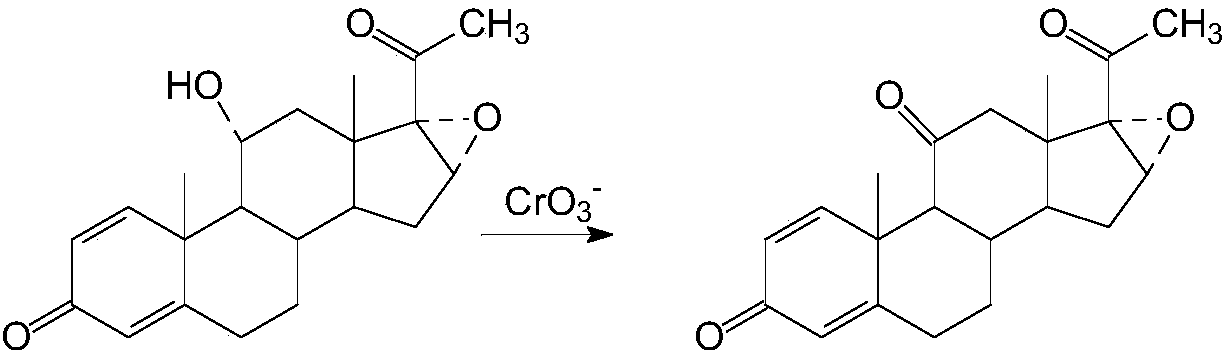

[0023] Oxide preparation: Add 95 parts of mold dehydrogenation products, 180 parts of glacial acetic acid, and 35 parts of chromic anhydride to the reaction kettle, stir and react for 4 to 5 hours at a temperature of 35-38°C, and add 1700 parts of concentration to the water analysis kettle 5% caustic soda aqueous solution for water analysis, centrifugation and filtration to obtain oxides.

[0024] Preparation of protective material: add 90 parts of oxides, 40-60 parts of glacial acetic acid, 1500 parts of water, 35 parts of methyl carbazate in the reaction kettle, react for 10 hours at a temperature of 20-25 ° C, and centrifugally filter to obtain protection. thing.

[0025] Preparation of closed-loop hydrolyzate: Add 120 parts of protective materials and 750 parts of chloroform into the reaction kettle, stir, control the temperature at 25-28°C, feed nitrogen, keep warm for 24-30 hours, and after the reaction is complete, pump the materials into the washing kettle. Add water ...

Embodiment 2

[0029] Preparation of oxides: Add 90 parts of mold dehydrogenation products, 200 parts of glacial acetic acid, and 30 parts of chromic anhydride into the reaction kettle, stir and react for 4 to 5 hours at a temperature of 35-38°C, and add 1600 parts of concentration to the water analysis kettle 5% caustic soda aqueous solution for water analysis, centrifugation and filtration to obtain oxides.

[0030] Preservation preparation: Add 90 parts of oxides, 50 parts of glacial acetic acid, 1600 parts of water, 40 parts of methyl carbazate into a reaction kettle, react at 20-25°C for 10 hours, and centrifuge to obtain the protection.

[0031] Preparation of closed-loop hydrolyzate: Add 120 parts of protective material and 800 parts of chloroform into the reaction kettle, stir, control the temperature at 25-28°C, feed nitrogen gas, keep warm for 24-30 hours, and after the reaction is complete, pump the material into the washing kettle. Add water to wash once, dry chloroform under neg...

Embodiment 3

[0035] Preparation of oxides: add 110 parts of mold dehydrogenation products, 240 parts of glacial acetic acid, and 40 parts of chromic anhydride in the reaction kettle, stir and react for 4 to 5 hours at a temperature of 35-38°C, and add 1900 parts of concentration in the water analysis kettle 5% caustic soda aqueous solution for water analysis, centrifugation and filtration to obtain oxides.

[0036] Preservation preparation: add 95 parts of oxides, 60 parts of glacial acetic acid, 1900 parts of water, 50 parts of methyl carbazate in a reaction kettle, react at a temperature of 20-25°C for 10 hours, and centrifuge to obtain the protection.

[0037]Preparation of closed-loop hydrolyzate: Add 130 parts of protective material and 900 parts of chloroform into the reaction kettle, stir, control the temperature at 25-28°C, feed nitrogen, keep warm for 24-30 hours, and after the reaction is complete, pump the material into the washing kettle. Add water to wash once, dry the chlorof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com