Epoxy resin composition for carbon fiber prepreg

A technology of carbon fiber prepreg and epoxy resin, which is applied in the field of materials, can solve the problems of insufficient epoxy resin storage and practicability, and is not easy to disperse, and achieve the effects of low curing shrinkage, strong bonding force, and high product dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the epoxy resin composition of the present invention is to uniformly mix the raw materials of the epoxy resin composition according to their proportions.

[0043] The prepreg of the present invention can be produced by dissolving the epoxy resin composition of the present invention in an organic solvent, impregnating it into reinforcing fibers, taking it out, and evaporating the solvent using an oven or the like; The resin composition is heated to impregnate the reinforcing fibers, and then it is only necessary to take it out and cool it.

[0044] The carbon fiber-reinforced epoxy resin composite material of the present invention can be obtained by thermocompression curing molding of the above-mentioned carbon fiber prepreg.

[0045] The epoxy resin composition of the present invention and its carbon fiber prepreg and carbon fiber composite material can be used in various aspects of industrial production and people's life, such as aerospace fie...

Embodiment 1~17

[0086] The epoxy resin compositions of Examples 1-17 were added into an internal mixer according to the raw materials and proportions shown in Table 2, kneaded at 160° C. for 20 minutes, and cooled to room temperature.

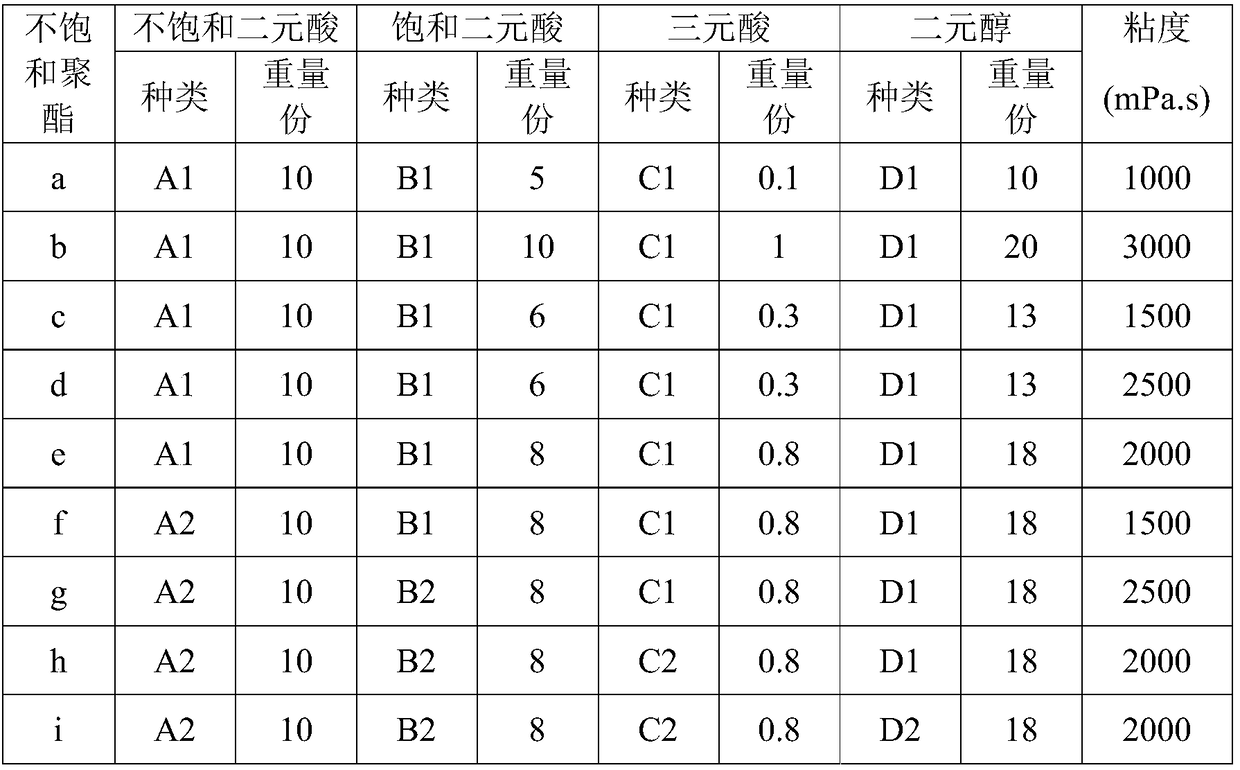

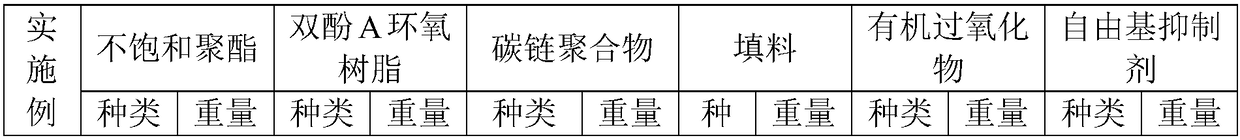

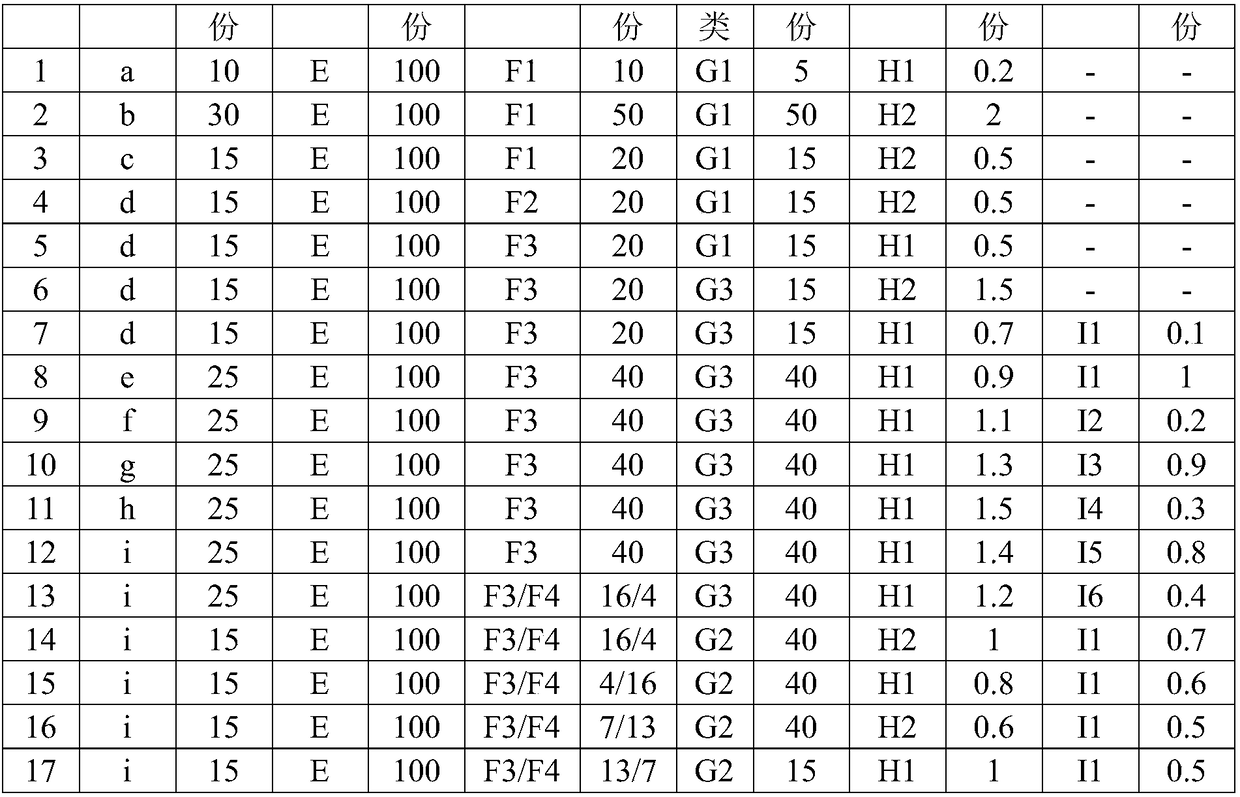

[0087] Table 2 Epoxy resin composition

[0088]

[0089]

[0090] Among them, "-" indicates that it does not contain free radical inhibitors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com