Vehicle PC/ABS alloy and preparation method thereof

An alloy and automotive technology, applied in the field of automotive PC/ABS alloy and its preparation, can solve the problems of unsuitability for extrusion molding, low elongation at break, affecting the use effect of plates, etc., to improve melt fluidity, The effect of good smoothness, excellent mechanical properties and low temperature impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of above-mentioned PC / ABS alloy for vehicle comprises the following steps:

[0043] 1) drying acrylonitrile-butadiene-styrene copolymer, polycarbonate, methyl methacrylate-butadiene-styrene copolymer, compatibilizer and flame retardant;

[0044] 2) Combine acrylonitrile-butadiene-styrene copolymer, polycarbonate, methyl methacrylate-butadiene-styrene copolymer, compatibilizer, flame retardant, anti-warping agent and antioxidant Mix evenly, then transfer to a twin-screw extruder, extrude, pelletize, and dry to obtain PC / ABS alloy pellets for vehicles.

[0045] Preferably, the drying described in step 1) is carried out at 75-85° C., and the drying time is 3-5 hours.

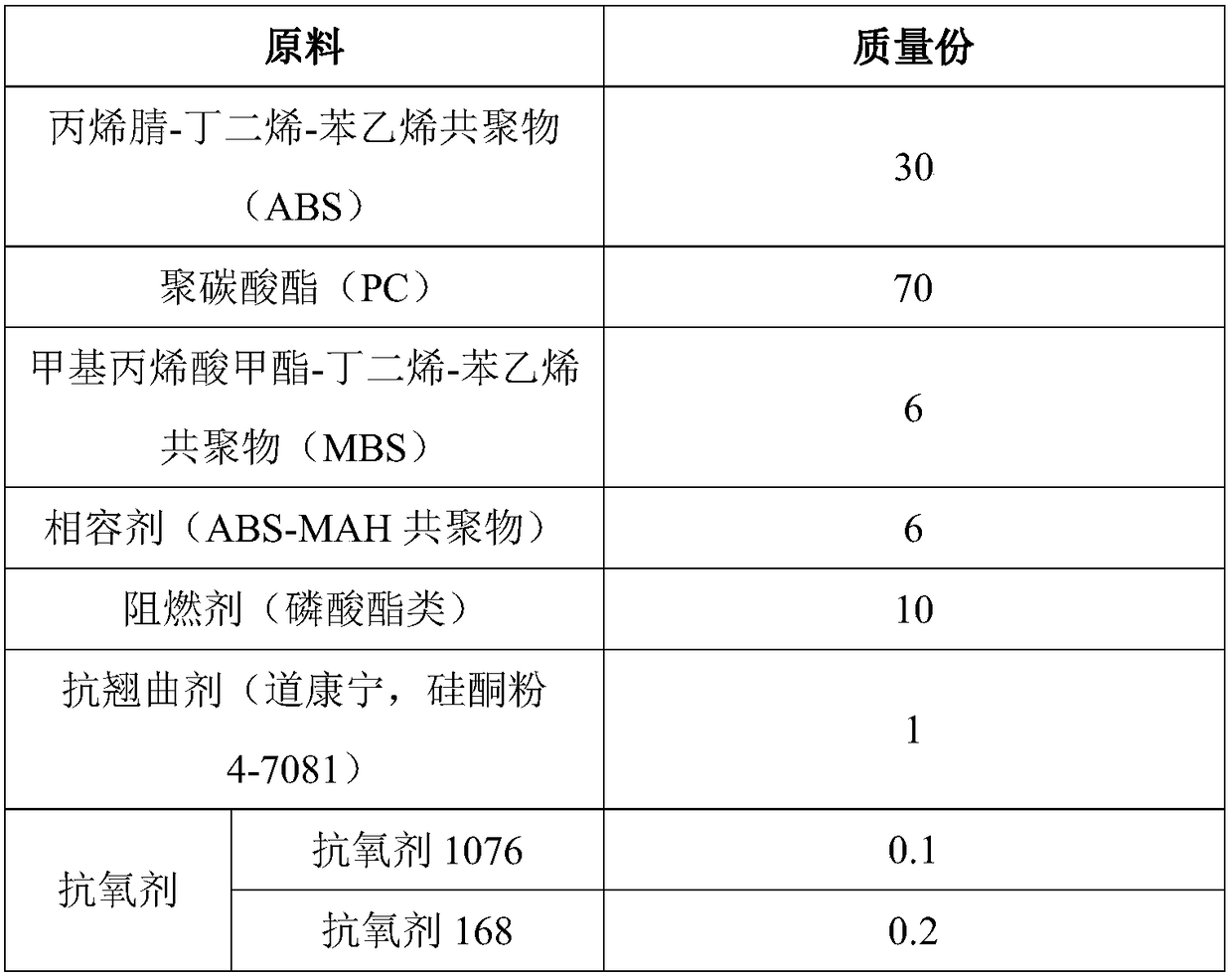

Embodiment 1

[0048] A kind of PC / ABS alloy for automobile, its raw material composition is as shown in the following table:

[0049] Table 1 The raw material composition table of a kind of vehicle PC / ABS alloy

[0050]

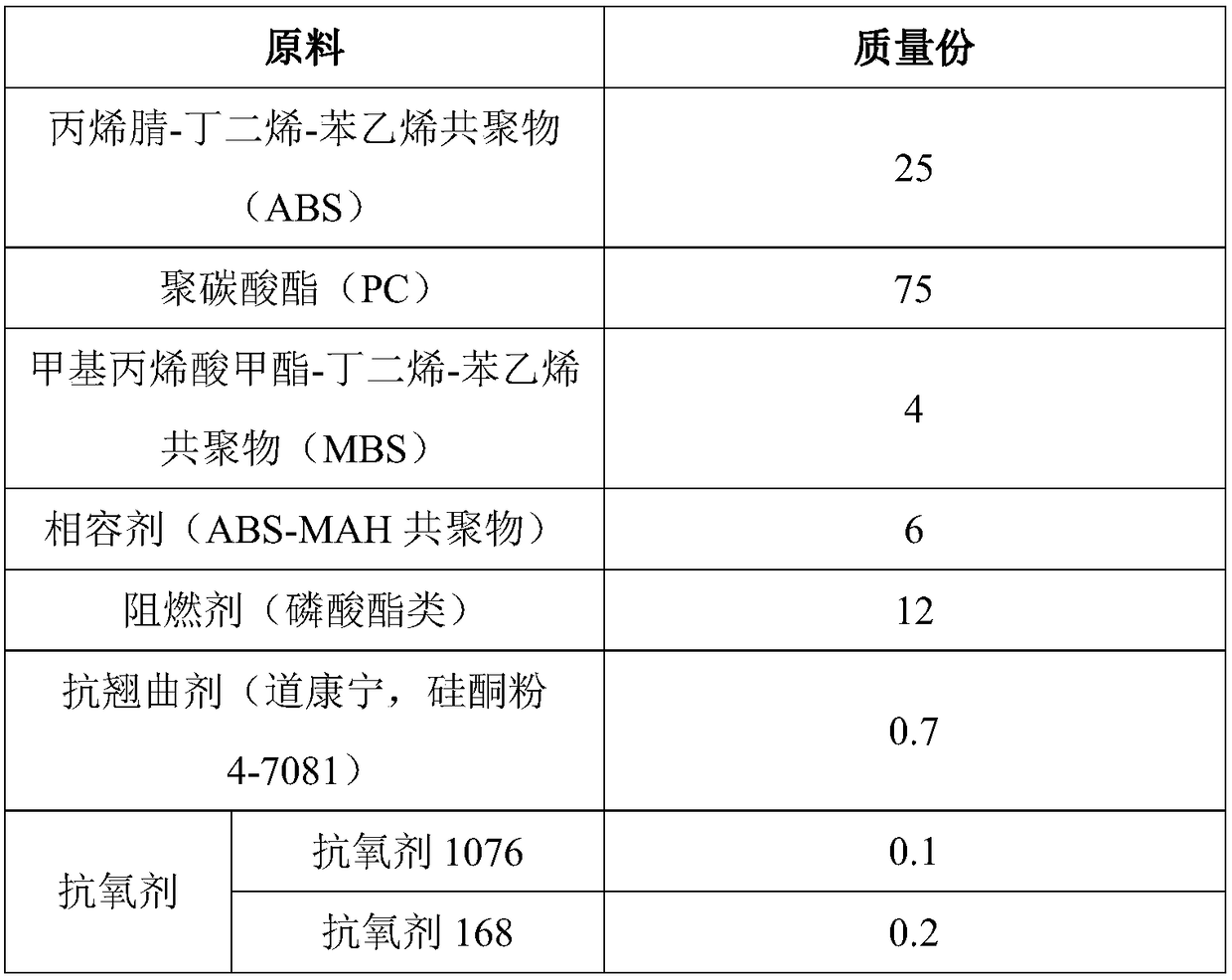

Embodiment 2

[0052] A kind of PC / ABS alloy for automobile, its raw material composition is as shown in the following table:

[0053] Table 2 The raw material composition table of a kind of vehicle PC / ABS alloy

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com