Method for preparing lightweight environment-friendly high-near infrared emissivity material and application thereof

An infrared emissivity and environment-friendly technology, applied in the direction of coating, etc., can solve the problems of affecting the grilling effect of high-firing tubes, not having infrared heating effect, and endangering food health, so as to improve the infrared grilling effect, the preparation method is simple and efficient, and the energy The effect of less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

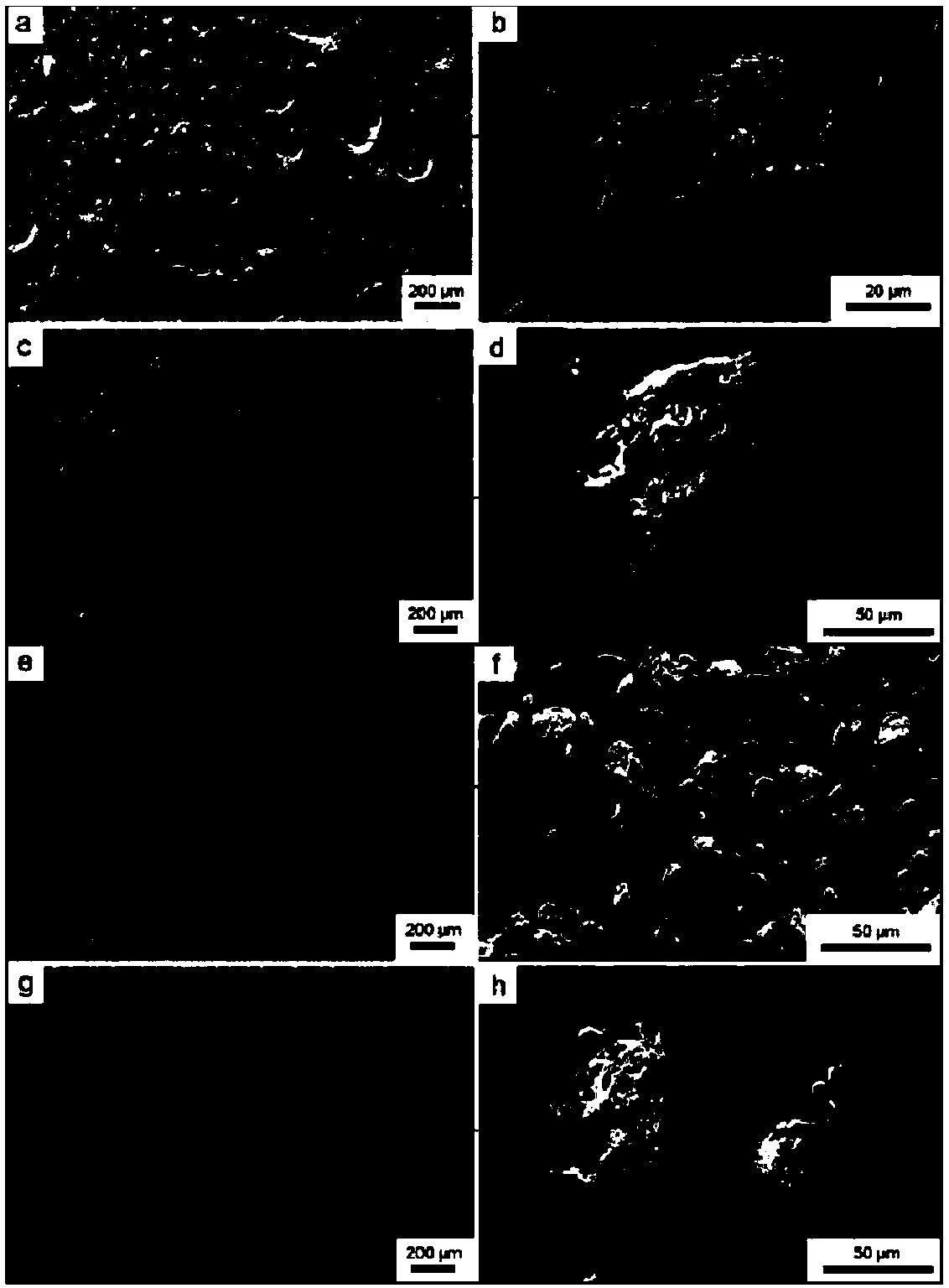

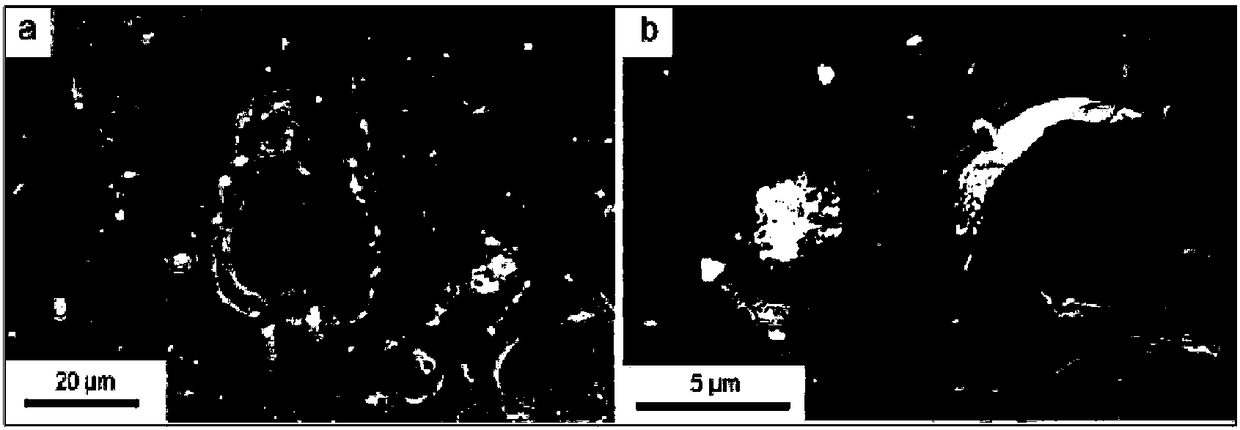

Embodiment 1

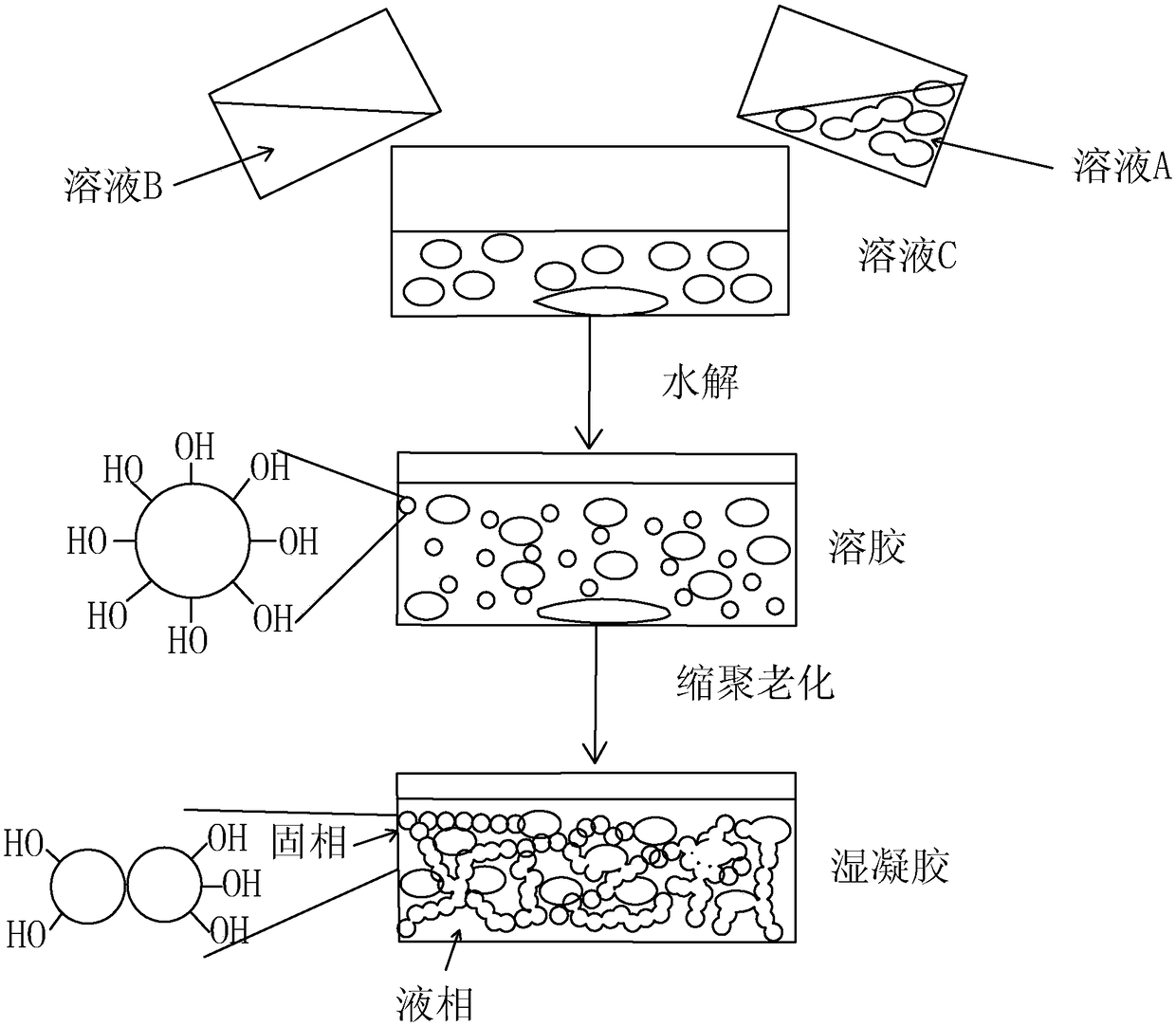

[0028] Step 1, take 9g of spherical graphite, place in a 1000mL beaker, add 150mL of absolute ethanol solution, ultrasonically disperse for 30min, and obtain solution A for subsequent use;

[0029] Step 2, 25.64g Mg(NO 3 ) 2 ·6H 2 O and 37.51g Al(NO 3 ) 3 9H 2 O, add an appropriate amount of deionized water, place the solution in a water bath at 60°C and stir for 30 minutes to obtain solution B;

[0030] Step 3: Pour solution A into solution B, and continuously stir for 30 minutes, then adjust the temperature of the water bath to 80°C, adjust the pH value of the mixed solution to 3 with ammonia water (25wt%), and stir for 30 minutes to obtain solution C ;

[0031] Step 4, slowly add an appropriate amount of tetraethyl orthosilicate in solution C, wherein their molar ratio is n (正硅酸乙酯) :n (硝酸铝) =5:2; after adding tetraethyl orthosilicate, adjust the temperature of the water bath to 90°C, allow it to stir for 1h to obtain solution D, and pay attention to adding deionized...

Embodiment 2

[0039] Step 1, get the spherical graphite of 15g, place in the beaker of 1000mL, add the absolute ethanol solution of 200mL, ultrasonic dispersion 30min, obtain solution A for subsequent use;

[0040] Step 2, 38.64g Mg(NO 3 ) 2 ·6H 2 O and 37.51g Al(NO 3 ) 3 9H 2 O, add an appropriate amount of deionized water, place the solution in a water bath at 60°C and stir for 30 minutes to obtain solution B;

[0041] Step 3: Pour solution A into solution B, and continuously stir for 30 minutes, then adjust the temperature of the water bath to 80°C, adjust the pH value of the mixed solution to 4 with ammonia water (25wt%), and stir for 30 minutes to obtain solution C ;

[0042] Step 4, slowly add an appropriate amount of tetraethyl orthosilicate in solution C, wherein their molar ratio is n (正硅酸乙酯) :n (硝酸铝) =6:2; after adding tetraethyl orthosilicate, adjust the temperature of the water bath to 90°C, allow it to stir for 1h to obtain solution D, and pay attention to adding deioni...

Embodiment 3

[0050] Step 1, get the spherical graphite of 7g, be placed in the beaker of 1000mL, add 100mL absolute ethanol solution, ultrasonic dispersion 30min, obtain solution A for subsequent use;

[0051] Step 2, 25.64g Mg(NO 3 ) 2 ·6H 2 O and 37.51g Al(NO 3 ) 3 9H 2 O, add an appropriate amount of deionized water, place the solution in a water bath at 60°C and stir for 30 minutes to obtain solution B;

[0052] Step 3: Pour solution A into solution B, and continuously stir for 30 minutes, then adjust the temperature of the water bath to 80°C, adjust the pH value of the mixed solution to 3 with ammonia water (25wt%), and stir for 30 minutes to obtain solution C ;

[0053] Step 4, slowly add an appropriate amount of tetraethyl orthosilicate in solution C, wherein their molar ratio is n (正硅酸乙酯) :n (硝酸铝) =5.4:2; After adding tetraethyl orthosilicate, adjust the temperature of the water bath to 90°C, allow it to stir for 1h to obtain solution D, and pay attention to adding deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com