Two-ingredient polyurethane adhesive as well as preparation method and application thereof

A two-component polyurethane and adhesive technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as unstable chemical properties, poor vibration resistance, and low bonding strength. Achieve enhanced toughness and anti-aging performance, improve compression resistance, and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A two-component polyurethane adhesive, the adhesive includes component A and component B, component B is liquefied MDI, component A and component B are mixed uniformly at a mass ratio of 3:1 to obtain Two-component polyurethane adhesive.

[0047](1) Preparation of component A:

[0048] Polyether polyol: 95 parts polyether polyol 330N;

[0049] Polymer polyol: 3 parts polymer polyol POP36 / 28;

[0050] Cross-linking agent: 1 part propylene glycol;

[0051] Foam stabilizer: 0.1 part;

[0052] Inert silicone oil: 0.1 part of ethyl silicone oil.

[0053] Tertiary amine gel catalyst: 0.1 part catalyst A33;

[0054] Tertiary amine foaming catalyst: 0.1 part of catalyst A1;

[0055] Foaming agent: 0.5 parts of HCFC-141b (a fluorodichloroethane);

[0056] Special silicone oil: 0.1 parts.

[0057] At 25°C, add the above materials into the reaction kettle, stir and mix, and after 2 hours, the product of component A can be obtained.

[0058] (2) Use of two-component polyur...

Embodiment 2

[0062] A two-component polyurethane adhesive, the adhesive includes component A and component B, component B is liquefied MDI, component A and component B are uniformly mixed in a mass ratio of 4:1 to obtain Two-component polyurethane adhesive.

[0063] (1) Preparation of component A:

[0064] Polyether polyol: 77.759 parts polyether polyol 330N;

[0065] Polymer polyol: 15.552 parts polymer polyol POP36 / 28;

[0066] Crosslinking agent: 3.110 parts of ethylene glycol;

[0067] Foam stabilizer: 0.389 parts;

[0068] Inert silicone oil: 0.233 parts of simethicone.

[0069] Tertiary amine gel catalyst: 0.467 parts catalyst A33;

[0070] Tertiary amine foaming catalyst: 0.156 parts of catalyst A1;

[0071] Blowing agent: 2.333 parts of HCFC-141b (a fluorodichloroethane);

[0072] Special silicone oil: 0.001 parts.

[0073] At 20°C, add the above materials into the reaction kettle, stir and mix, and after 2 hours, the product of component A can be obtained.

[0074] (2) Us...

Embodiment 3

[0078] A two-component polyurethane adhesive, the adhesive includes component A and component B, component B is liquefied MDI, component A and component B are uniformly mixed in a mass ratio of 2:1 to obtain Two-component polyurethane adhesive.

[0079] (1) Preparation of component A:

[0080] Polyether polyol: 50 parts polyether polyol 330N;

[0081] Polymer polyol: 28 parts polymer polyol POP36 / 28;

[0082] Cross-linking agent: 6 parts of 1,4-butanediol;

[0083] Foam stabilizer: 2 parts;

[0084] Inert silicone oil: 2 parts simethicone.

[0085] Tertiary amine gel catalyst: 1.8 parts catalyst A33;

[0086] Tertiary amine foaming catalyst: 1.2 parts catalyst A1;

[0087] Blowing agent: 8 parts of HCFC-141b (one fluorodichloroethane);

[0088] Special silicone oil: 1 part.

[0089] At 15°C, add the above materials into the reaction kettle, stir and mix, and after 2 hours, the product of component A can be obtained.

[0090] (2) Use of two-component polyurethane adhes...

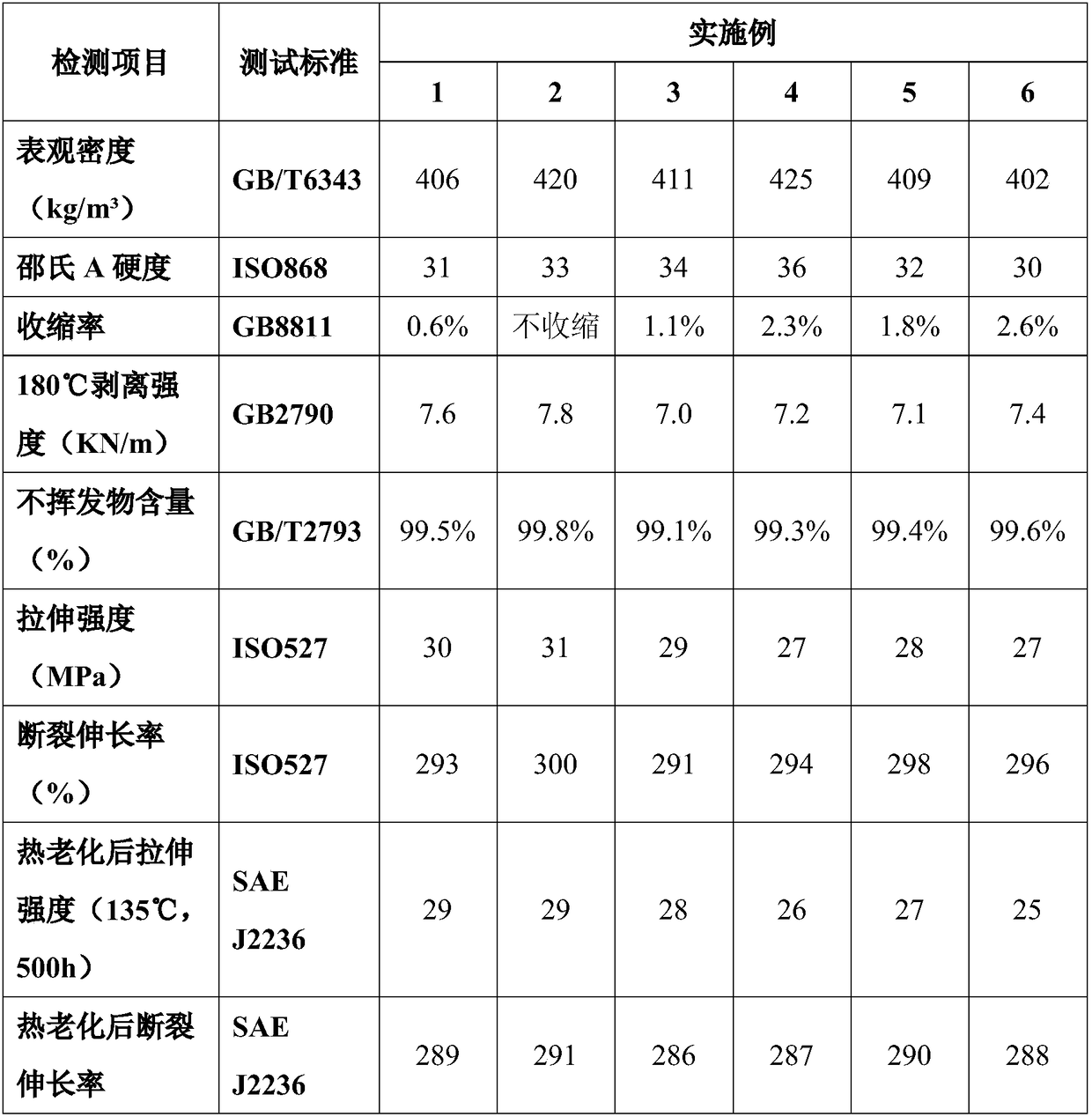

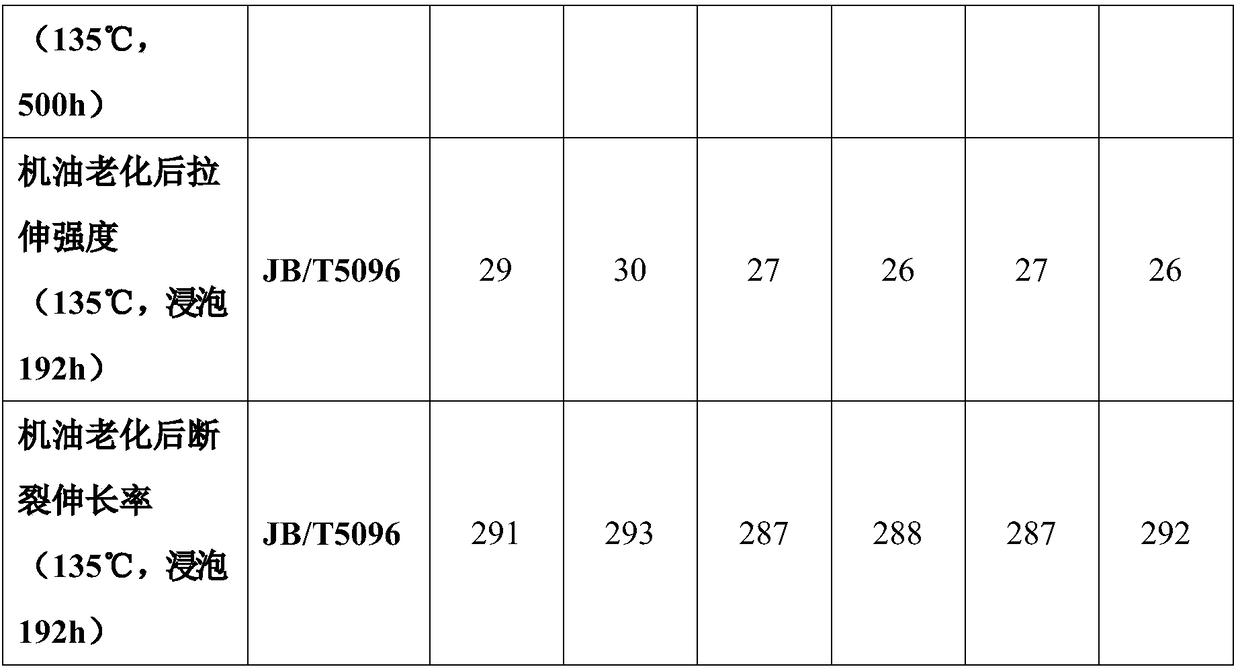

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com