Snowflake type steel sheet pile and its processing method

A processing method and technology of steel sheet piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large pile settlement and insufficient bearing capacity of single piles, and achieve improved pile bearing capacity, small settlement, and control The effect of pile deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

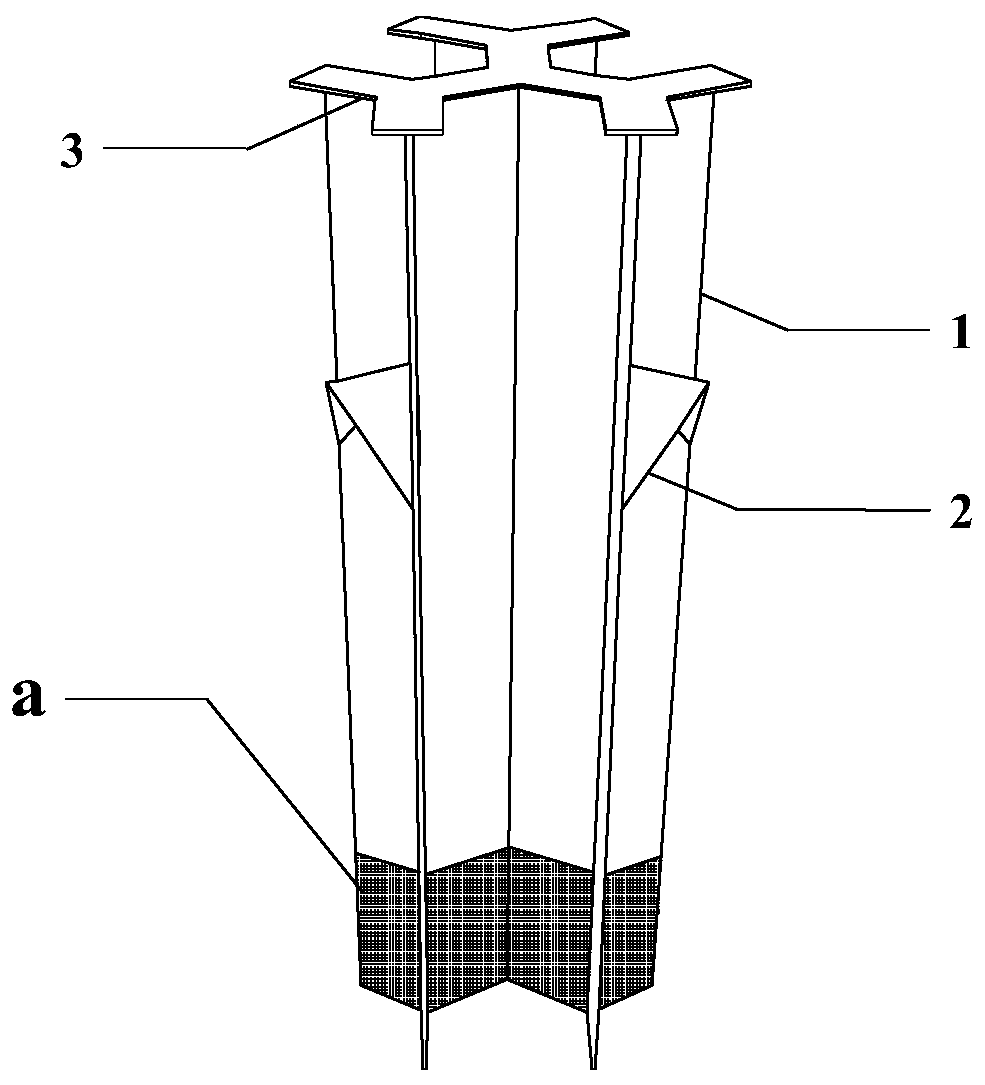

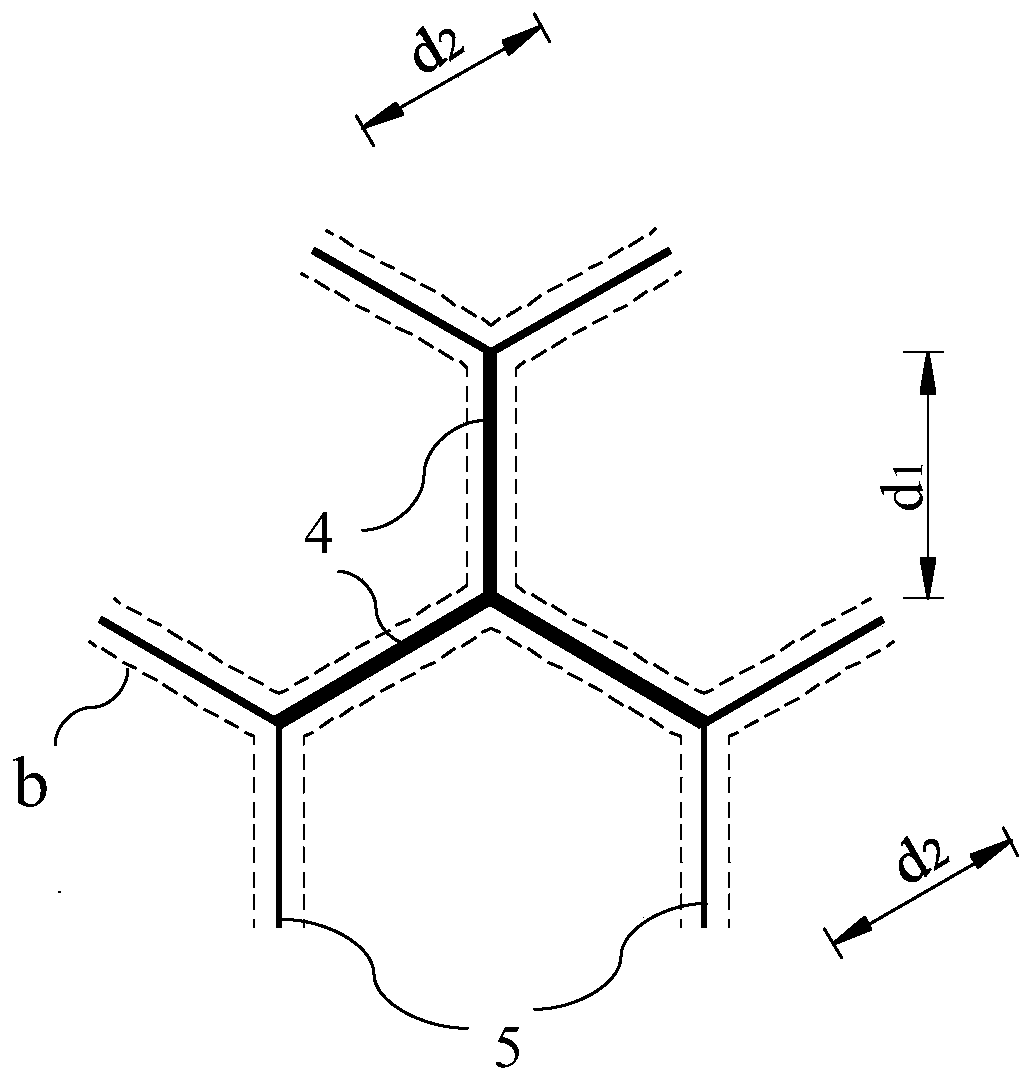

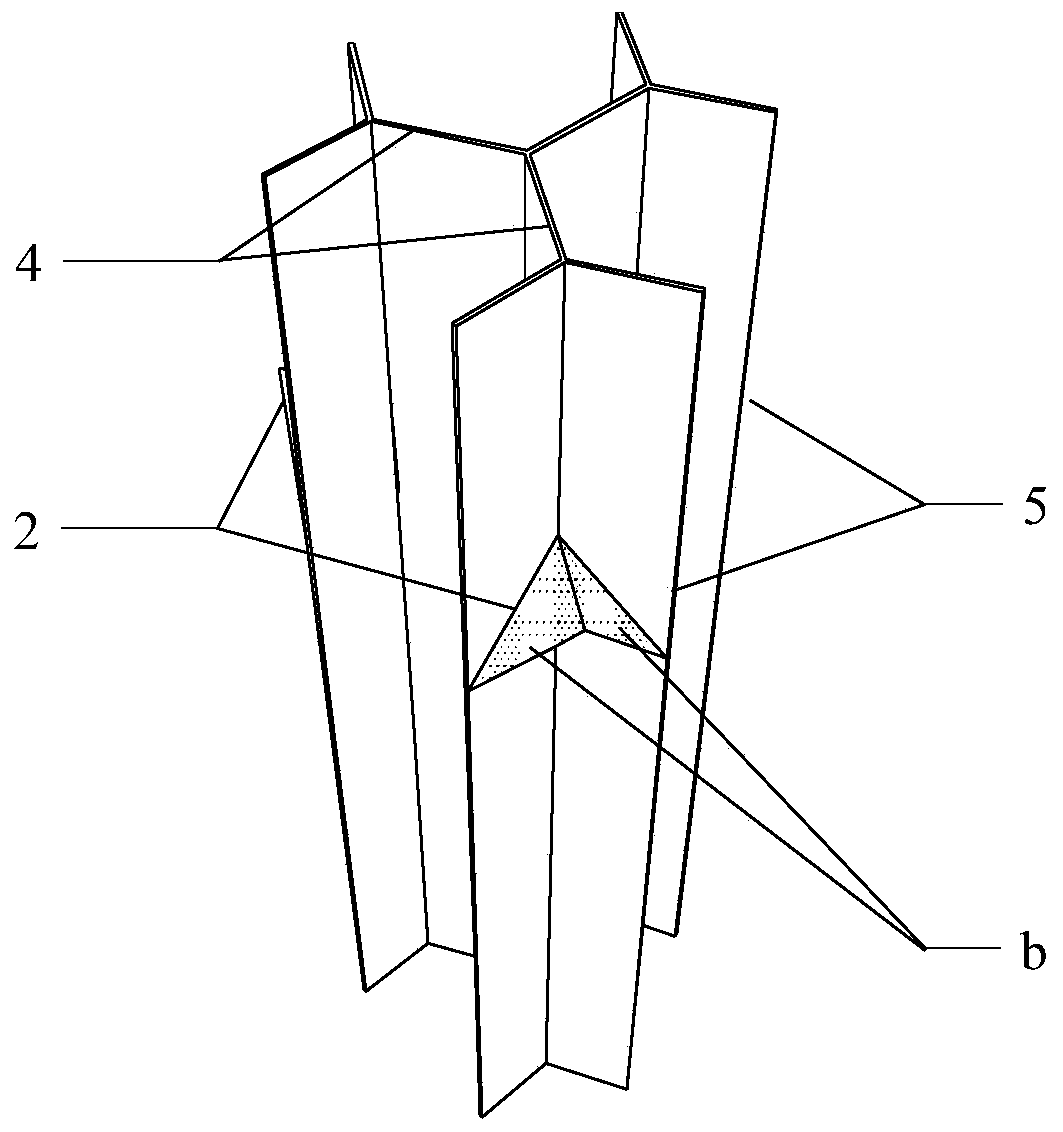

[0032] Such as figure 1 As shown, the steel sheet pile includes a pile body 1, a support plate 2 and a pile cap 3; the material of the pile body 1 is a steel plate, and the lower end 1 / 5 of its length is a smooth surface a. The support plate 2 is located at 1 / 3 of the length of the upper end of the pile body 1, and is extruded outward in a triangular shape, and then squeezes part of the soil toward the hole wall to increase the side friction of the steel sheet pile; because the additional stress on the soil is spindle shape distribution, and it is the largest at the depth of 1 / 3 from the surface, then the location of the support plate 2 conforms to the law of stress diffusion in the soil around the pile, which is conducive to the pile body being fully stressed and achieving a small settlement of the pile body. The pile cap 3 is a widened steel plate with the same shape as the pile body 1, and forms an external expansion on the outer wall of the pile body 1, which enhances the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com