Preparation method for anti-smashing glove

A technology for gloves and anti-smashing, applied in gloves, protective clothing, clothing, etc., can solve the problems of small elasticity of stainless steel wire, poor cushioning performance, poor air permeability, etc., and achieve the effect of less manual injury and enhanced cushioning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present embodiment provides a kind of preparation method of anti-smashing gloves, specifically comprises the following steps:

[0025] S0, preparing bead glue and dipping glue.

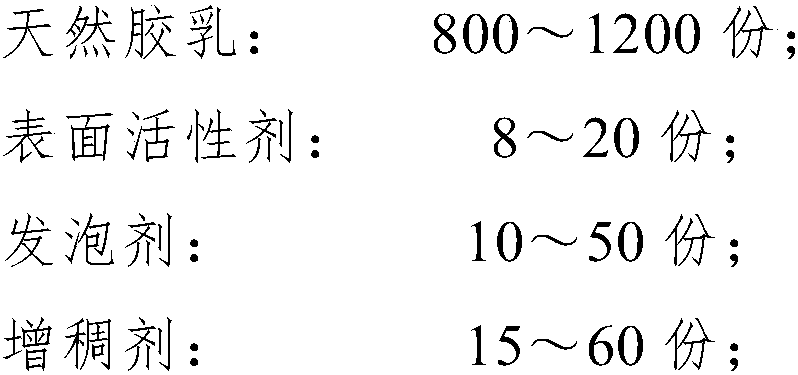

[0026] Specifically, the preparation method of above-mentioned bead glue comprises the steps:

[0027] a1, 1000 parts of natural rubber latex are pre-vulcanized by a sulfur vulcanization system to obtain pre-vulcanized latex. Among them, during the pre-vulcanization process, the natural latex molecular chains are partially vulcanized, and the natural latex molecules are quickly cross-linked to form a network structure. This process is carried out inside the natural latex particles, so that the natural latex corresponding Geophysical changes and chemical changes, thereby improving its physical and mechanical properties. The swelling index (that is, the Q value, representing the degree of crosslinking, the higher the Q value, the lower the degree of crosslinking) of the final prevulcanized ...

Embodiment 2

[0047] The present embodiment provides a kind of preparation method of anti-smashing gloves, specifically comprises the following steps:

[0048] S0, preparing bead glue and dipping glue.

[0049] Specifically, the preparation method of above-mentioned bead glue comprises the steps:

[0050] a1, 800 parts of natural rubber latex were pre-vulcanized by thiuram vulcanization system to obtain pre-vulcanized latex. The Q value of the prevulcanized latex finally obtained is 5.5, the mechanical stability is greater than 2000s, the viscosity reaches 75MPa s, the 300% modulus stress reaches 0.95MPa, the tensile strength reaches 28MPa, and the elongation at break reaches 800%. Process requirements.

[0051] a2. Add 8 parts of sodium dodecylbenzenesulfonate to the prevulcanized latex obtained in step a1, and mix it evenly by stirring or vibrating.

[0052] a3. Add 10 parts of sodium bicarbonate to the mixed solution obtained in step a2, and mix evenly by stirring or shaking.

[0053...

Embodiment 3

[0065] The present embodiment provides a kind of preparation method of anti-smashing gloves, specifically comprises the following steps:

[0066] S0, preparing bead glue and dipping glue.

[0067] Specifically, the preparation method of above-mentioned bead glue comprises the steps:

[0068] a1. 950 parts of natural rubber latex were pre-vulcanized by a resin vulcanization system to obtain pre-vulcanized latex. The Q value of the prevulcanized latex finally obtained is 5.0, the mechanical stability is greater than 3200s, the viscosity reaches 80MPa s, the 300% modulus stress reaches 0.99MPa, the tensile strength reaches 30MPa, and the elongation at break reaches 880%. Process requirements.

[0069] a2. Add 6 parts of sodium dodecylbenzene sulfonate and 9 parts of Pingpingjia to the prevulcanized latex obtained in step a1, and mix them evenly by stirring or shaking.

[0070] a3. Add 20 parts of sodium carbonate and 15 parts of benzenesulfonyl hydrazide to the mixed solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical stability | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com