Preparation method of high strength and high toughness bamboo plywood

A high-toughness, bamboo plywood technology, which is applied in the jointing of wooden veneers, flat products, manufacturing tools, etc., can solve problems such as poor strength, toughness, weak integrity, and easy cracking of the surface, and achieve chemical bonding. The effect of increasing, improving cohesion, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

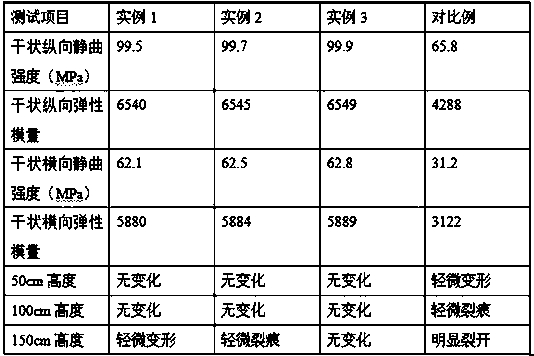

Examples

example 1

[0026] Select a bamboo curtain with a size of 460mm×460mm×2mm, put the bamboo curtain into a high-pressure cooker, add a sodium hydroxide solution with a concentration of 0.5mol / L into the high-pressure cooker until the bamboo curtain is completely submerged, and seal the high-pressure Cooking pot, increase the pressure in the high-pressure cooking pot to 1.5MPa, heat and boil for 6 hours to obtain pretreated bamboo curtains; after the above-mentioned heating and boiling treatment is completed, immediately take out the pretreated bamboo curtains and put them into an autoclave with an air inlet , then add the water of 10 times of the quality of phenol and bamboo curtain quality such as pretreatment bamboo curtain in the autoclave and the sodium hydroxide of bamboo curtain quality 5%, seal reactor; Feed steam until the pressure in the reactor reaches 1.0MPa, stop feeding steam and raise the temperature of the reactor to 175°C, stir and react at a speed of 200r / min for 50min, afte...

example 2

[0028]Select a bamboo curtain with a size of 460mm×460mm×2mm, put the bamboo curtain into a high-pressure cooker, add a sodium hydroxide solution with a concentration of 0.5mol / L into the high-pressure cooker until the bamboo curtain is completely submerged, and seal the high-pressure Cooking pot, increase the pressure in the high-pressure cooking pot to 1.7MPa, heat and boil for 7 hours, and obtain the pretreated bamboo curtain; after the above-mentioned heating and boiling treatment is completed, immediately take out the pretreated bamboo curtain and put it into an autoclave with an air inlet , then add the water of 12 times of the phenol of quality such as pretreatment bamboo curtain and bamboo curtain quality and the sodium hydroxide of bamboo curtain quality 5% in autoclave, seal reactor; Feed steam until the pressure in the reactor reaches 1.1MPa, stop feeding steam and raise the temperature of the reactor to 177°C, and stir and react at a speed of 250r / min for 60min. Aft...

example 3

[0030] Select a bamboo curtain with a size of 460mm×460mm×2mm, put the bamboo curtain into a high-pressure cooker, add a sodium hydroxide solution with a concentration of 0.5mol / L into the high-pressure cooker until the bamboo curtain is completely submerged, and seal the high-pressure Cooking pot, increase the pressure in the high-pressure cooking pot to 2.0MPa, heat and boil for 8 hours to obtain pretreated bamboo curtains; after the above-mentioned heating and boiling treatment is completed, immediately take out the pretreated bamboo curtains and put them into an autoclave with an air inlet , then add the water of 15 times of the phenol of quality such as pretreatment bamboo curtain and bamboo curtain quality and the sodium hydroxide of bamboo curtain quality 5% in autoclave, seal reactor; Feed steam until the pressure in the reactor reaches 1.2MPa, stop feeding steam and raise the temperature of the reactor to 180°C, stir and react at a speed of 300r / min for 70min, after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com