Clostridium butyricum fermentation method for obviously improving yield of butyric acid

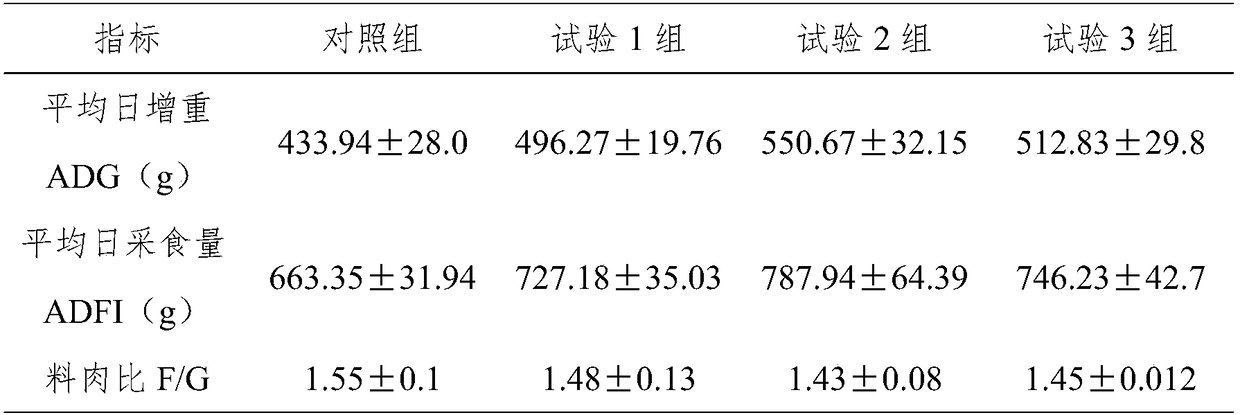

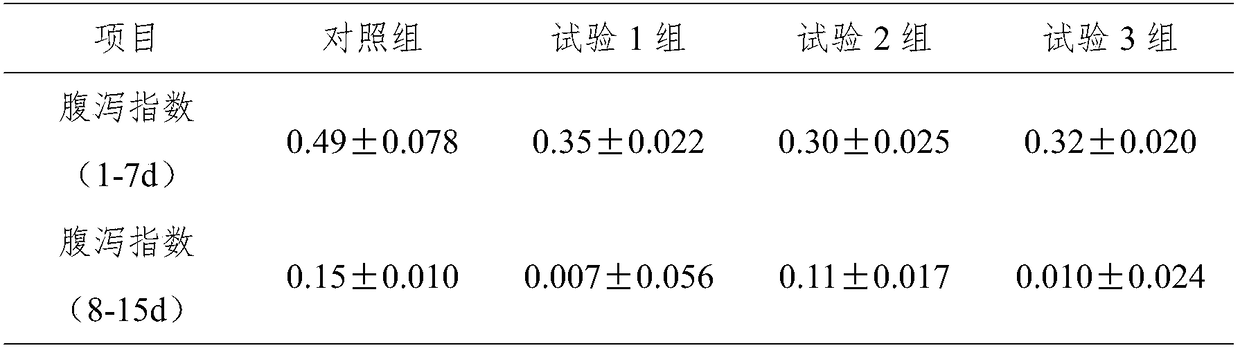

A technology of Clostridium butyricum and fermentation method, applied in the directions of microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problem of few studies on extracting butyric acid, etc., to improve animal production performance, reduce diarrhea rate, The effect of increasing growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A clostridium butyricum fermentation method significantly improving butyric acid production, said clostridium butyricum fermentation method significantly improving butyric acid production comprises the following steps:

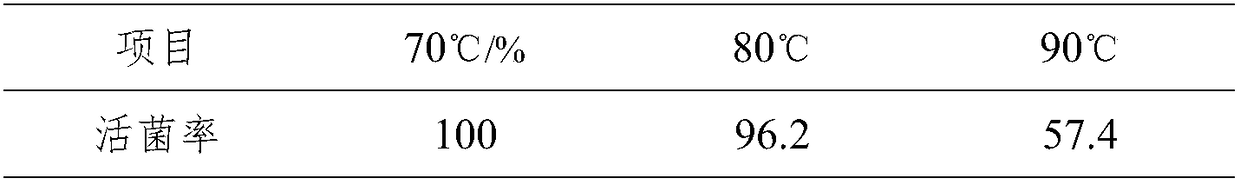

[0025] S1. Inoculate Clostridium butyricum into the culture medium and cultivate until the pH of the culture medium is less than 3.5. In the early stage of Clostridium butyricum spore formation, tolerance treatment is carried out in a water bath at 82°C every 7 hours, and the tolerance treatment is collected. Bacteria solution, isolate resistant strains;

[0026] S2. Inoculate the tolerant strain in step S1 into a liquid shake flask culture medium and cultivate it to the logarithmic phase to obtain first-class seeds;

[0027] S3. Take 1% of the total amount of the primary seed bacteria in step S2 and inoculate it into the primary culture medium in the 50L seed tank, and cultivate it to the logarithmic growth phase to obtain the secondary seed;

[0028]...

Embodiment 2

[0033] A clostridium butyricum fermentation method significantly improving butyric acid production, said clostridium butyricum fermentation method significantly improving butyric acid production comprises the following steps:

[0034] S1. Inoculate Clostridium butyricum into the culture medium and cultivate until the pH of the culture medium is less than 3.5. In the early stage of Clostridium butyricum spore formation, tolerance treatment is carried out in a water bath at 80°C every 6 hours, and the tolerance treatment is collected. Bacteria solution, isolate resistant strains;

[0035] S2. Inoculate the tolerant strain in step S1 into a liquid shake flask culture medium and cultivate it to the logarithmic phase to obtain first-class seeds;

[0036] S3. Take 1% of the total amount of the primary seed bacteria in step S2 and inoculate it into the primary culture medium in the 50L seed tank, and cultivate it to the logarithmic growth phase to obtain the secondary seed;

[0037]...

Embodiment 3

[0041] A clostridium butyricum fermentation method significantly improving butyric acid production, said clostridium butyricum fermentation method significantly improving butyric acid production comprises the following steps:

[0042] S1. Inoculate Clostridium butyricum into the culture medium and cultivate until the pH of the culture medium is less than 3.5. During the early stage of Clostridium butyricum spore formation, tolerance treatment is carried out in a water bath at 85°C every 8 hours, and the tolerance treatment is collected. Bacteria solution, isolate resistant strains;

[0043] S2. Inoculate the tolerant strain in step S1 into a liquid shake flask culture medium and cultivate it to the logarithmic phase to obtain first-class seeds;

[0044] S3. Take 1% of the total amount of the primary seed bacteria in step S2 and inoculate it into the primary culture medium in the 50L seed tank, and cultivate it to the logarithmic growth phase to obtain the secondary seed;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com