Corrosion-resistant environmental-friendly zinc alloy

A zinc alloy and corrosion-resistant technology, applied in the field of alloys, can solve the problems of unsuitability for casting and poor fluidity, and achieve the effects of better alloy fluidity, enhanced bottom shrinkage resistance, and excellent polishing performance.

Inactive Publication Date: 2018-09-07

厦门格欧博新材料科技有限公司

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The alloy has high tensile strength, elongation and shear strength, but has poor fluidity and is not suitable for casting

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

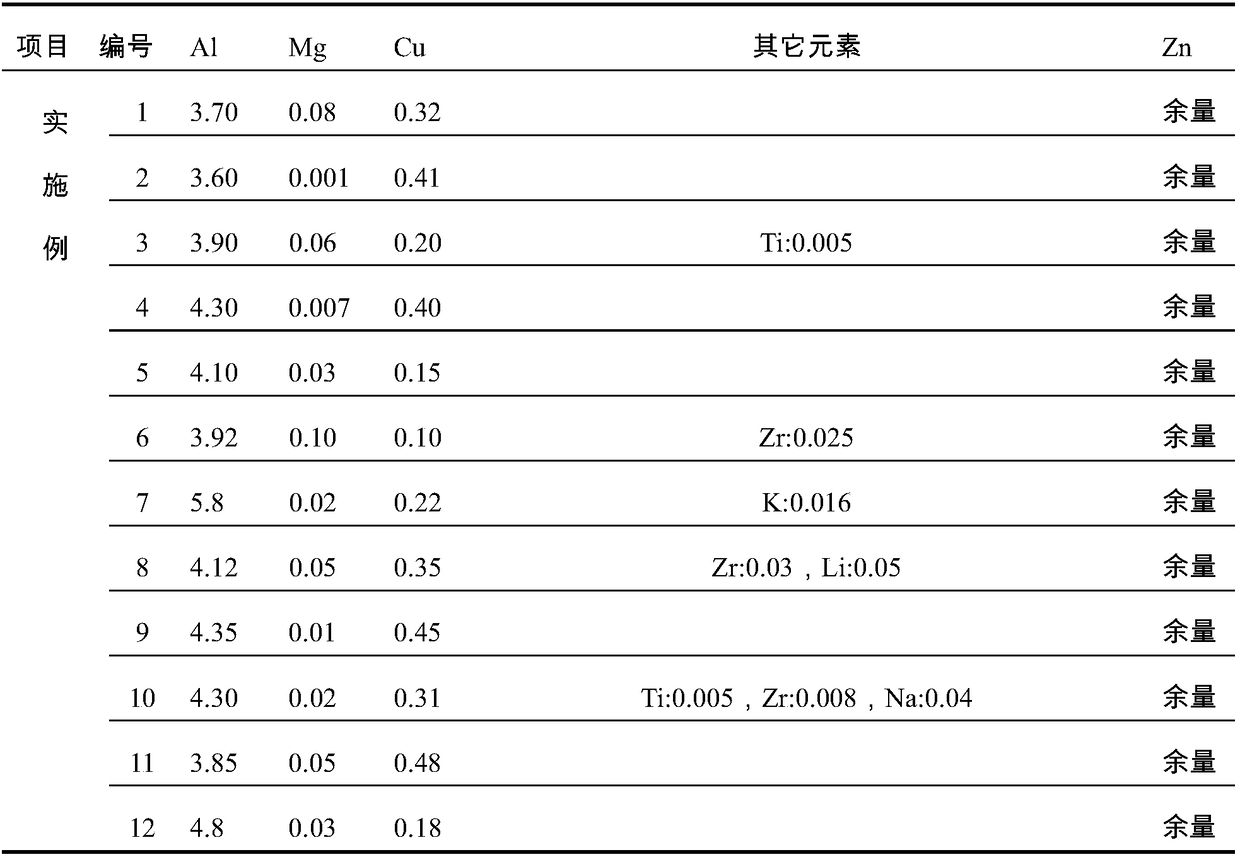

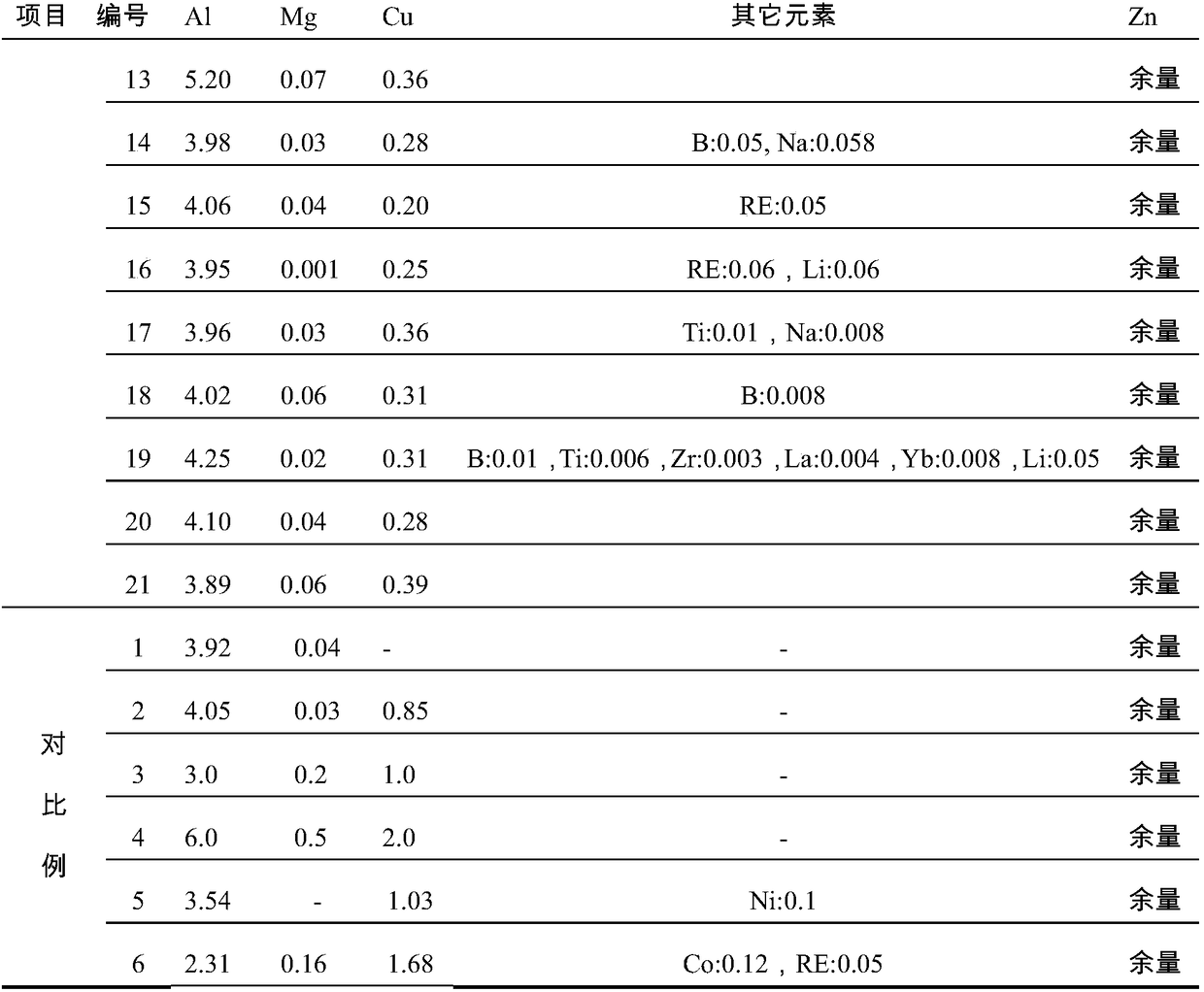

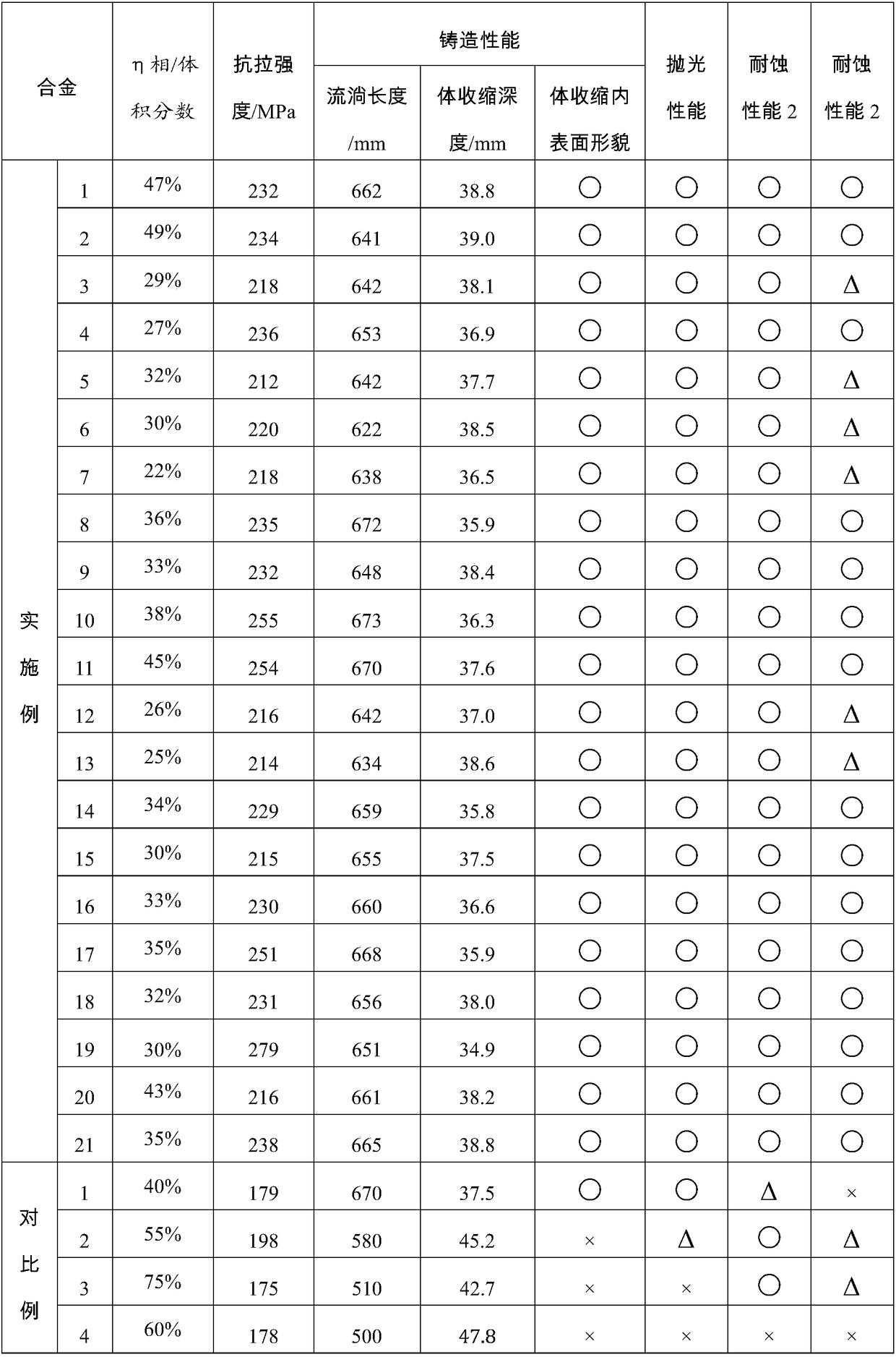

[0045] The compositions of the corrosion-resistant and environment-friendly zinc alloys provided by the examples and comparative examples of the present invention are shown in Table 1.

[0046] Table 1 Corrosion-resistant environmental protection zinc alloy composition table (wt%)

[0047]

[0048]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a corrosion-resistant environmental-friendly zinc alloy and relates to the technical field of alloys. The corrosion-resistant environmental-friendly zinc alloy comprises the following components in percentage by weight: 3.6-5.8% of Al, 0.1-0.48% of Cu, 0.001-0.1% of Mg and the balance of Zn and inevitable impurities, wherein the mass ratio of Al to Cu is 8-30; the microstructure of the zinc alloy comprises an eta phase and a beta phase; the volume percentage of the eta phase is less than 50%. The alloy has excellent casting properties, corrosion resistance and polishingand electroplating properties, is applicable to components and elements of water heating bathroom accessories, small hardware accessories and the like manufactured through pressure casting and gravityor low-pressure casting.

Description

technical field [0001] The invention relates to the technical field of alloys, and in particular to a corrosion-resistant and environment-friendly zinc alloy. Background technique [0002] As an important non-ferrous metal, zinc is used in the third place after aluminum and copper, and zinc is used to produce zinc-based alloys, which occupies the second place in zinc consumption, mainly used in the production of die-casting zinc alloys and Gravity cast zinc alloy. [0003] Compared with other non-ferrous metals, die-casting zinc alloy has the characteristics of low melting point, good fluidity and formability, low energy consumption, and low raw material cost. The surface of die-casting castings is smooth, especially suitable for polishing and electroplating. Die-casting zinc alloys commonly used in the manufacturing industry are Zn-Al alloys containing about 4wt% Al. %), ZAMAK5 (Cu: 0.7-1.1wt%), ZAMAK7 (Cu≤0.1wt%) alloys, ZAMAK3 and ZAMAK7 alloys in this series of alloys ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C18/04

CPCC22C18/04

Inventor 杨力泽胡胜

Owner 厦门格欧博新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com