Degradable hot air non-woven fabric and preparation method thereof

A non-woven fabric, hot air technology, applied in non-woven fabrics, textiles and papermaking, fiber processing, etc., can solve the problems of non-biodegradability, pollution, white environment, etc. Simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

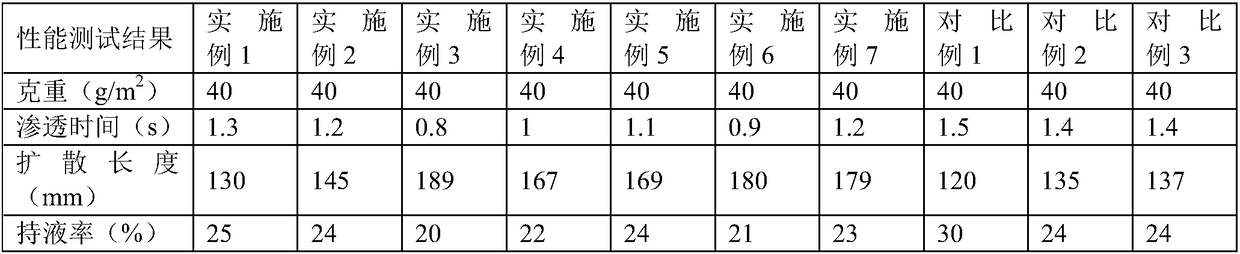

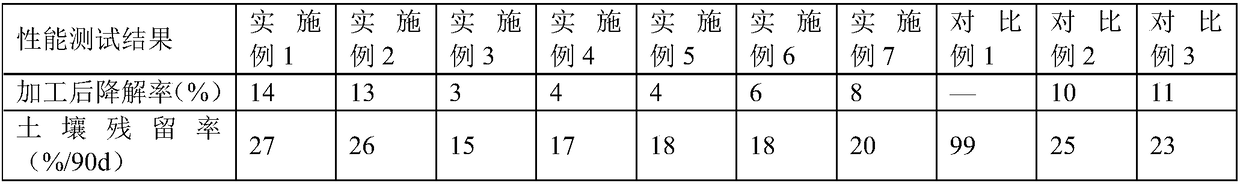

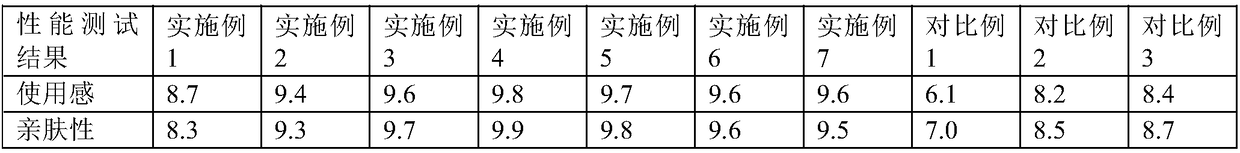

Examples

Embodiment 1

[0024] Mechanical carding: 15 kg of PLA fibers with a skin-core structure are mechanically carded to form a fiber web; the skin and core layers of the PLA fibers are both PLA, and the melting point of the skin layer PLA is 130 ° C. The melting point of the core layer PLA is 160 ° C. ℃, the skin-to-core ratio is 1:1, and the fineness of the PLA fiber with the skin-to-core structure is 4.4dtex;

[0025] Hot-air bonding: under hot air at 134°C, the PLA fibers at the overlapping joints were melt-bonded to prepare a degradable air-through nonwoven fabric with a thickness of 2 mm.

Embodiment 2

[0027] Mechanical carding: Evenly mix 7.5 kg of PLA fibers with a skin-core structure and 7.5 kg of single-component PLA fibers, and then overlap each other to form a fiber web after mechanical carding; the melting point of the single-component PLA fibers is 160 ° C, and the skin-core structure The material of the skin layer and the core layer of the PLA fiber is PLA, the melting point of the skin layer PLA is 130°C, the melting point of the core layer PLA is 160°C, and the ratio of skin to core is 1:1. PLA fiber with skin-core structure and single-component PLA fiber The fineness is 4.4dtex;

[0028] Hot-air bonding: under hot air at 134°C, the PLA fibers at the overlapping joints were melt-bonded to prepare a degradable air-through nonwoven fabric with a thickness of 2 mm.

Embodiment 3

[0030] Pretreatment: Take 7.5kg of PLA fiber with skin-core structure and 7.5kg of single-component PLA fiber, irradiate with ultraviolet device for 25 minutes, then put PLA fiber into 35kg of treatment solution with a concentration of 4%, and blow nitrogen gas for 11 minutes to fully swell Finally, the excess treatment solution was poured out, and then irradiated with an ultraviolet device for 25 minutes, then boiled in distilled water for 2.5 hours, and then dried; wherein, the treatment solution was composed of poly(α-D-galactosyl-D-glucoside) and D - Prepared from mannitol, the mass ratio of poly(α-D-galactosyl-D-gluconoside) to D-mannitol is 1:3, and the solvent is water;

[0031] Mechanical carding: Evenly mix 7.5kg of pretreated PLA fibers with a sheath-core structure and 7.5kg of single-component PLA fibers, and overlap each other to form a fiber web after mechanical carding; the melting point of the single-component PLA fibers is 160°C The material of the skin layer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com